More than EM – A Multi-Discipline Approach to Motor Design

I recently read a very interesting IEEE paper called Modern Electrical Machine Design Optimization: Techniques, Trends, and Best Practices. In the first few paragraphs, there was some staggering facts about electric motors around the world and how they are powered.

Here are some key points:

- The total amount of electric energy generated globally projected by year 2020 is 26000 TWh and it is about to increase towards 30000 TWh, which will be increasingly generated by electromechanical conversion

- There are about 300 million industrial electric motors in operation worldwide and that amount is increasing by 15% annually

- Motors are virtually everywhere. Millions are embedded in consumer products. And while HEV/EV is another example of where they are increasingly found, an internal combustion engine car may have 60 individual electric motors for all kinds of auxiliary systems.

- Electric motors for industrial applications use more than 40% of the total energy produced worldwide

- Electrical machinery is diverse in size and power consumption, varying from several megawatts and meters to just a few milliwatts and millimeters

- Their usage puts restrictions on efficiency, reliability and controllability

There is a lot to unpack in those bullet points, and each one could be a series of blog posts on their own. The emerging trends such as “electrification of everything”, an emphasis on increased mechanical efficiency and a worldwide interest in reducing dependence on non-renewable energy sources puts the same pressure on the design and manufacturing for all motors.

Emerging trends are easily explored with best-in-class CAE

However it is the following excerpt from the paper that was the most interesting:

“Improvements enable scenarios which cover evermore aspects of physics. In the past, machine design was equivalent to investigating electromagnetic performance. Nowadays thermal, rotor dynamics, power electronics and control aspects are included. Material and engineering science have introduced new dimensions on the optimization process and impact of manufacturing and unavoidable tolerances should be considered. “

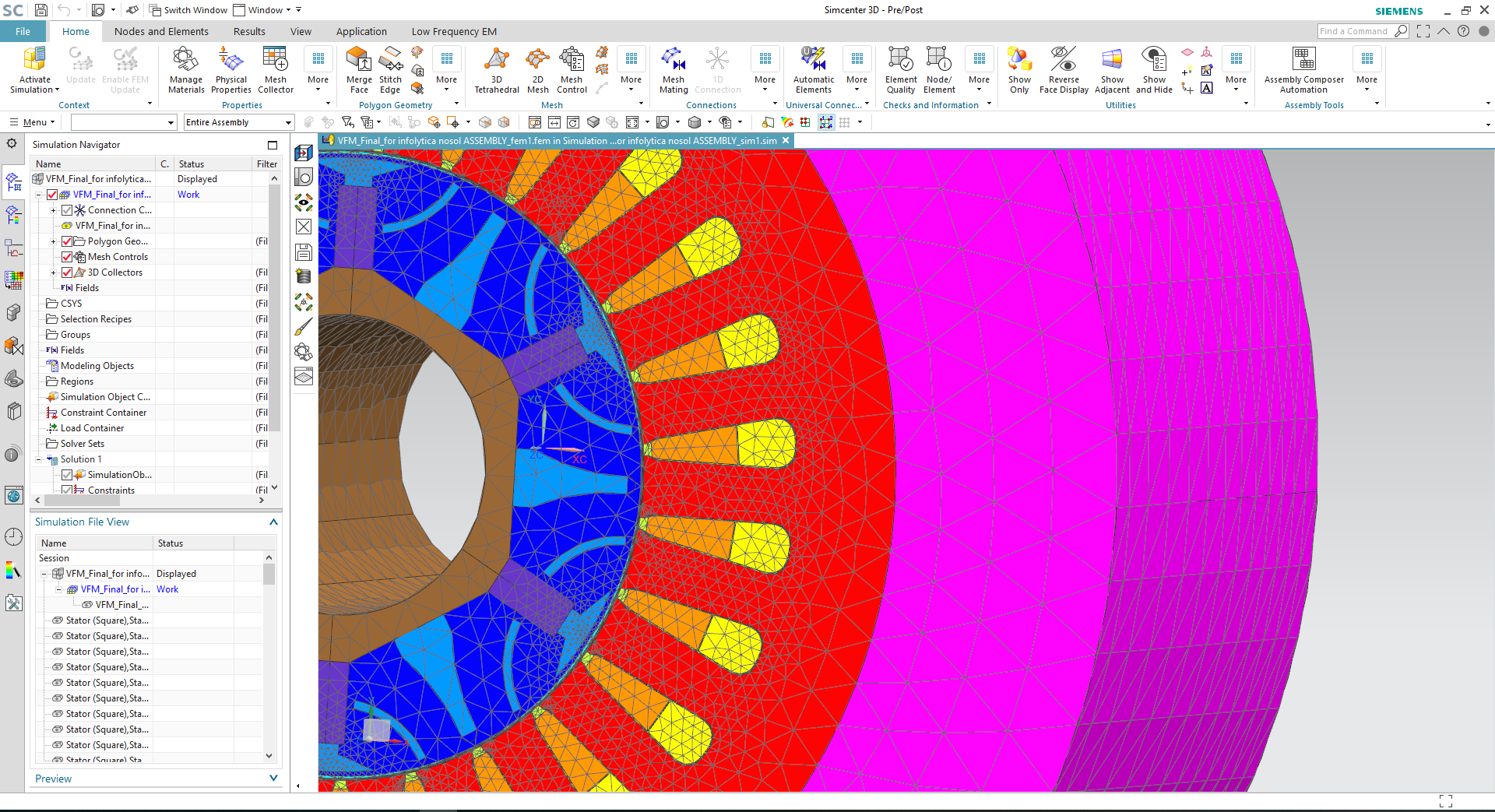

Without a doubt, an accurate electromagnetic performance simulation, such as that offered by finite element analysis, will continue to be an integral part of the electric motor design process. However to address the challenges highlighted above, this analysis must be part of a multiple discipline CAE simulation ecosystem which expands into thermal, electrical, structural, acoustics, fluid, vibrational analysis, etc.

The Simcenter 3D set of multi-discipline solutions will shortly be expanded to include new electromagnetic and electromechanical performance capabilities in 2019, responding to the emerging design challenges ahead for simple to complex electric motors, sensors, transformers, actuators, solenoids or any components with permanents magnets or coils – regardless of the restrictions, size or requirements.

Within this one 3D CAE environment, all the fast and accurate solvers required to explore modern electrical machine design and prototyping will be available. This short video features some of the soon to be available capabilities: