Bring multi-physics and durability testing to the next level

How rapid product and market changes impact durability engineering

Durability testing exists for a long time. Just think back to the Versailles Railway crash in 1842, as well as August Wohler, who discovered in 1858 that parts break after applying a certain number of cycles.

I’ve been doing durability testing projects during the past decades. Typically, I used to spend a lot of time on instrumentation—finding sensors and cable errors, calibrating, and also on post processing data, very often only some days after the tests were conducted. In those days, the number of prototypes to test was limited and the time available was reasonable.

Nowadays, product reliability is still a critical factor that makes or breaks the success of your products and of companies. But, new challenges make that engineering products for their reliability is under great pressure. Globalization enables manufacturers to distribute same products in many different countries across the globe to be used by many different users. Given the enormous variety of users behavior it has become extremely challenging to determine the correct loads the product will encounter during its lifetime. Next to this, there is a vast demand for more energy efficient products. As result, lightweight products are designed often using new and complex materials, in combination with smarter digital technologies and mechatronics. All this make the determination of fatigue life a great engineering challenge.

What’s more, with the increased amount of product variants, the number of required reliability tests has increased accordingly. And then, there is the market competitive pressure. You need to develop new product or advanced versions faster. So, how do you tackle this situation? What is the golden formula to succeed? The only solution to cope with these challenges is to improve the efficiency of your product reliability testing and seek for latest methodologies and advanced tools.

Siemens Simcenter Testlab Neo Efficiency

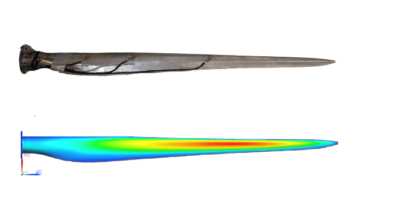

Performing multi-physics and durability testing with Simcenter Testlab Neo drastically improves your efficiency. Simcenter Testlab Neo offers a newly updated solution that offers one integrated platform for measuring and processing multi-physics data. The efficiency gains that can be obtained with Simcenter Testlab are diverse and radical. For example, recently we worked with an automotive company to improve their durability testing work. Some of the immediate efficiency gains obtained. (See above)

Learn more about the new software platform for testing engineers that is designed to guide you thought the durability testing campaigns and extend your testing options. Check out how you can obtain needed reliable data and durability insight faster.

Are you interested to learn how to perform durability load data analysis faster? Follow this webinar and find out how Simcenter Testlab Neo can bring your durability testing to the next level.

Comments

Comments are closed.