Efficient and accurate acoustic trim modeling with Simcenter 3D

Lighter. More efficient. Electrified. Those are the key aspirations of almost every car manufacturer today. The urgent necessity to reduce our carbon footprint is leading to a burst of innovation. New materials and manufacturing methods as well as complex multiphysics technologies grab all the attention. They radically change how vehicles are developed. Can engineers working on classic performance requirements such as noise, vibration and harshness (NVH) keep up?

Reducing weight limits NVH engineers in their margin of maneuver. At the same time, more efficient internal combustion engines require higher combustion pressure, which is detrimental for NVH. And powertrain electrification with E-motors and gearboxes leads to mid- to high-frequency noise in the cabin, both structure- and airborne. So how can NVH engineers effectively deal with these challenges?

Acoustic trim layers leading to better cabin comfort

One very important method to improve NVH performance, is noise control by applying sound-absorbent treatment on vibrating surfaces. Such an acoustic trim typically stacks layers of visco-elastic and poro-elastic materials. It is common practice in automotive and aerospace industries on components such as firewall, door panels, floor carpets, roof liner and more.

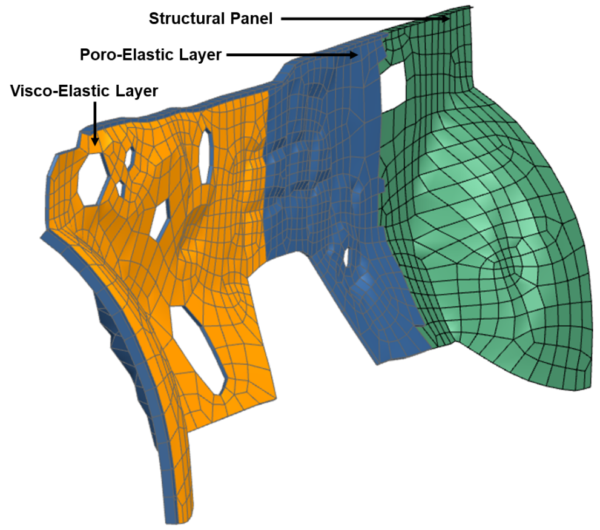

A typical setup for firewall treatment in cars, for example, includes 3 layers: the structural panel, a thick layer of porous material and a heavy visco-elastic covering layer. This combination provides efficient energy dissipation through structural damping as well as viscous and thermal losses. The outcome is increased transmission loss (TL), which leads to better cabin comfort.

Modeling acoustic trim with Simcenter 3D

Acoustic trim design and optimization require precise modeling methods and powerful acoustic simulation solutions. And that’s where Simcenter 3D Acoustics comes into play. The software has all the tools for NVH engineers to be successful. Let’s illustrate with a little example what we can do.

Sound transmission through an automotive firewall

Consider the trimmed panel in the picture below. It has the structural firewall panel, a layer of poro-elastic material on top, and then an additional layer of visco-elastic material to close the entire component.

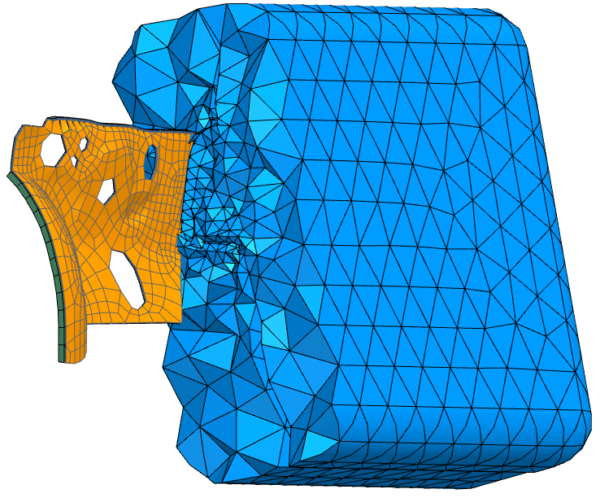

To calculate the sound transmission loss through this firewall panel, we added air on either side to represent acoustic cavities, as you can see in Figure 2. Note that the elements look coarse. They are designed to maximally exploit the strength of the finite element method with adaptive order (FEMAO), which we will describe below.

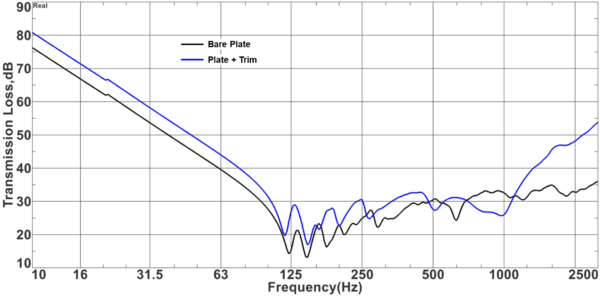

Figure 3 shows the expected sound transmission through the panel. The black and the blue curve show the TL through the untrimmed and trimmed firewall panels respectively. Next to an added mass effect visible at lower frequencies, you can clearly see the increased TL at higher frequencies (> 1000 Hz) thanks to the acoustic trim as well.

It’s all about accuracy

The accuracy of a TL prediction greatly depends on how well the properties of the poro-elastic materials can be described. Approaches like the transfer matrix method and equivalent fluid modeling with homogenized fluid phase are fast. But they miss precision. Simcenter 3D Acoustics also includes the full Biot approach. This one includes both the solid and fluid phases and can therefore account for most of the significant physical effects of the trim.

Instead of resolving acoustic pressure only, the full Biot formulation relates all 4 degrees of freedom of the solid and fluid phases (3 vibration components + 1 scalar acoustic pressure). This technique elegantly considers the interaction between the phases inside the poro-elastic material. These include elasticity, bulk mass and stiffness. Another advantage is that it facilitates coupling of the material to structure, fluids or other poro-elastic materials.

There is one drawback, however. Instead of solving for one degree-of-freedom, the formulation includes 4 variables. Full Biot modeling leads to a computationally expensive simulation problem that requires a powerful solver, especially considering the large frequency range of interest.

The powerful solver of Simcenter 3D Acoustics

Simcenter 3D Acoustics offers NVH engineers the perfect partner in crime for predicting transmission loss using full Biot modeling. The FEMAO solver technique is perfect fit to couple a detailed description of poro-elastic materials to an outstanding computational performance, even for high frequencies.

How it works? With FEMAO, engineers can accurately model the poro-elastic component using a relatively coarse mesh. When moving up in frequency, the solver maintains precision by automatically assigning higher polynomial orders to the interpolation functions that belong to poro-elastic elements. This order adaptivity applies to both the fluid and solid phase variables. The outcome is an accurate and utterly efficient solution.

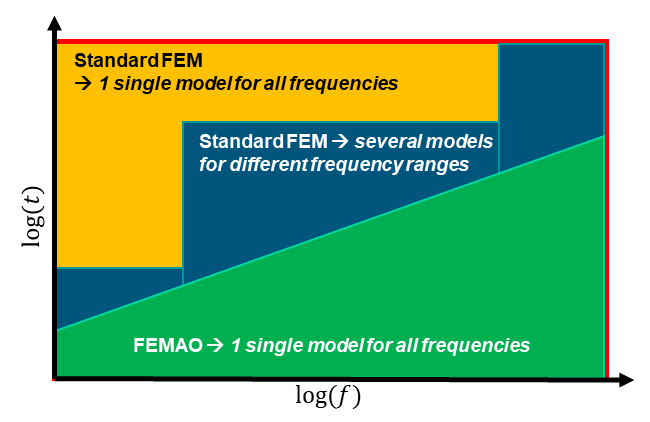

Figure 4 illustrates the benefits of FEMAO over standard FEM techniques. You can see how the method optimizes the computation time over a broad frequency range.

The entire process for acoustic trim modeling and simulation with FEMAO is available in the upcoming release Simcenter 3D 2021.2.

Related blogs

Did you think this was interesting to read? Then maybe you will also like the following blogs:

More about our FEM solvers in Simcenter 3D Acoustics:

- Efficient and Accurate Broadband FEM-based Vibro-acoustics (Part 1)

- Efficient and Accurate Broadband FEM-based Vibro-acoustics (Part 2) – External Acoustics

Read how our Simcenter testing colleagues can apply special techniques to measure high-frequency FRFs in luxury segment electric vehicles: