Efficient and Accurate Broadband FEM-based Vibro-acoustics (Part 2) – External Acoustics

Challenges of vibro-acoustic FE modeling for external acoustics

Two weeks ago I discussed how in Simcenter 3D Acoustics the FEMAO methodology we developed for vibro-acoustic analysis allows the acoustics engineers to accurately understand the acoustic performance of their product subject to a wide range of loads. By automatically adapting the element order of a mesh we are able to obtain accurate results while maintaining a coarse (and thus not computationally-intensive) mesh.

The second key technology is the Automatically Matched Layer (AML), a very flexible and efficient wave-absorbing method for external acoustics applications. External acoustics is about noise radiating to the environment, and with few exceptions – notably the distinctive acoustic exhaust notes of car engines– (my personal fave on this list #6 as that’s what I own ![]() ) it is rarely desirable and frequently can be an unwanted byproduct. Thus a primary objective in external acoustic applications can be noise mitigation. And undesirable noise can have a huge effect on the perception of quality of a product (or conversely in the case of exhausts).

) it is rarely desirable and frequently can be an unwanted byproduct. Thus a primary objective in external acoustic applications can be noise mitigation. And undesirable noise can have a huge effect on the perception of quality of a product (or conversely in the case of exhausts).

Given this context we can understand why the acoustic performance of a product is critical. To simulate these problems isn’t easy, because as the noise radiates it does so in all directions and essentially to “infinity”. But how do you model infinity? How big of a mesh is required? How many elements? Essentially how much is enough?

If you recall the discussion in the first part, effectively approximating reality comes down to modelization but this is the genius of the AML, as it acts as an absorbing boundary condition, the AML is applied at the outer boundary of a fluid volume mesh surrounding the sound radiating object. Now, the efficiency of the AML technology allows for using only a very small volume of actually meshed fluid. The only requirement of the fluid mesh is that its outer boundary is convex. Simcenter 3D offers dedicated meshing tools for acoustics, one of which provides you such convex AML boundary with a single click.

The AML property then automatically extrudes a virtual Perfectly Matched Layer (PML) region, surrounding the FEM region, and in which the outgoing waves are absorbed. The element order and the number of layers in the PML region are determined automatically by the solver, based on the input mesh, and the frequency of interest, without further user intervention.

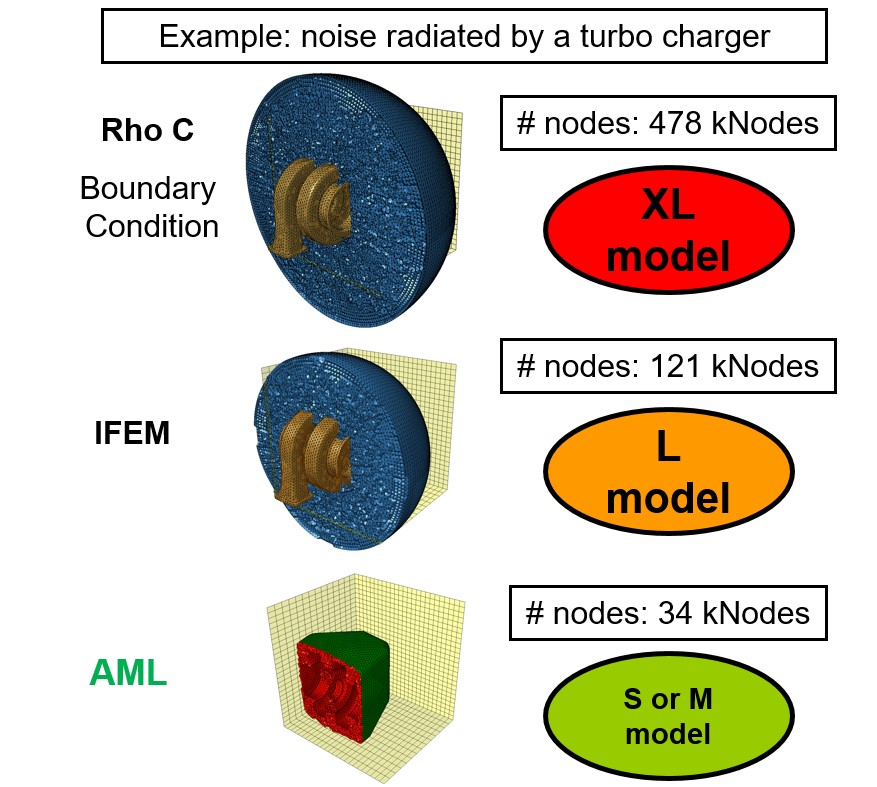

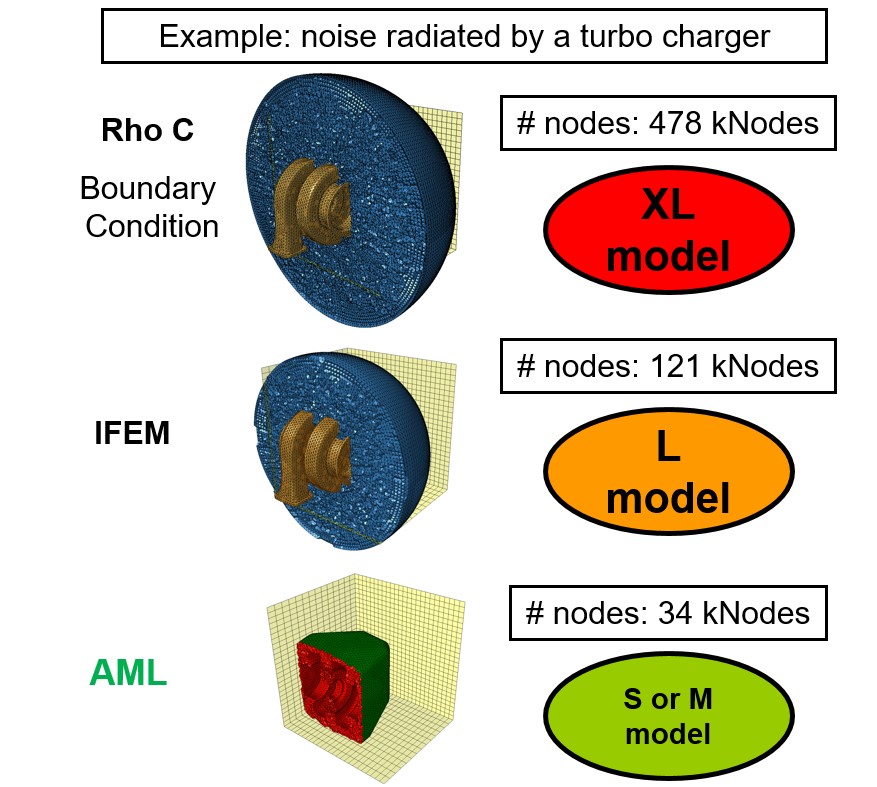

As can be seen from the turbocharger example below, this offers a large mesh size benefit (two orders of magnitude fewer number of nodes) as compared to traditional methods; these include applying a Rho-c boundary condition and using an infinite FEM (IFEM) approach.

Summary

These innovative technologies are the result of in-house Research work at Siemens PLM Software together with leading academia, in close collaboration with end users for methodology validation on their cases of interest. In particular:

-

- AML was developed as part of the IWT/VLAIO funded project “MIDAS” together with KU Leuven [2]

With the combination of both FEMAO and AML, the key mesh-based disadvantages of standard FEM are eliminated, such that a broadband frequency range acoustics prediction process based on FEM becomes a reality, for both interior and exterior acoustics applications. The methodologies’ integration into Simcenter 3D is done in the frame of the VLAIO project “HEAVENS”, with attention to the democratization of simulation methodologies in the product lifecycle management process. This targets to widen the usage base of acoustics simulation methods, from the specialist acoustics engineering experts to the much wider general FE analyst community. This helps expanding the vibro-acoustics knowledge across a team of general analysts, and jointly pursuing vibro-acoustics targets in balance with the multi-attribute product targets in the entire team.

[2] “Bériot, H. (2013). The Automatically Matched Layer Method for efficient exterior Acoustics radiation modelling, internal Siemens Communication (2013).”