Embeddable BCI-ROM Technology: reduced order thermal models for 3D CFD electronics cooling simulation

In this blog I introduce a novel reduced order modeling approach that adds significant value to package thermal model exchange in the electronics supply chain. Embeddable BCI-ROM technology enables creation of accurate reduced order thermal models of IC Packages that can be used in 3D CFD electronics cooling simulation studies. The accuracy of an embeddable BCI-ROM is close to the detailed thermal model and crucially, all internal construction details (dimensions and materials used) of the package are not present and thus cannot be reverse engineered. Embeddable BCI-ROM technology is a new feature in the recently released Simcenter Flotherm 2310 software. Read onward for an outline of thermal challenges, the solution, a demonstration and package thermal modeling accuracy comparisons.

What are some challenges in electronics supply chain for package thermal modeling?

Influencing factors:

– Modern package architectures such as 2.5D, 3DIC, chiplet based designs have complex thermal management challenges that require 3D thermal simulation to resolve.

– Performing 3D thermal analysis with suitable fidelity during package integration into electronics products and systems is even more crucial with modern package complexity and power densities.

Thermal modeling challenges:

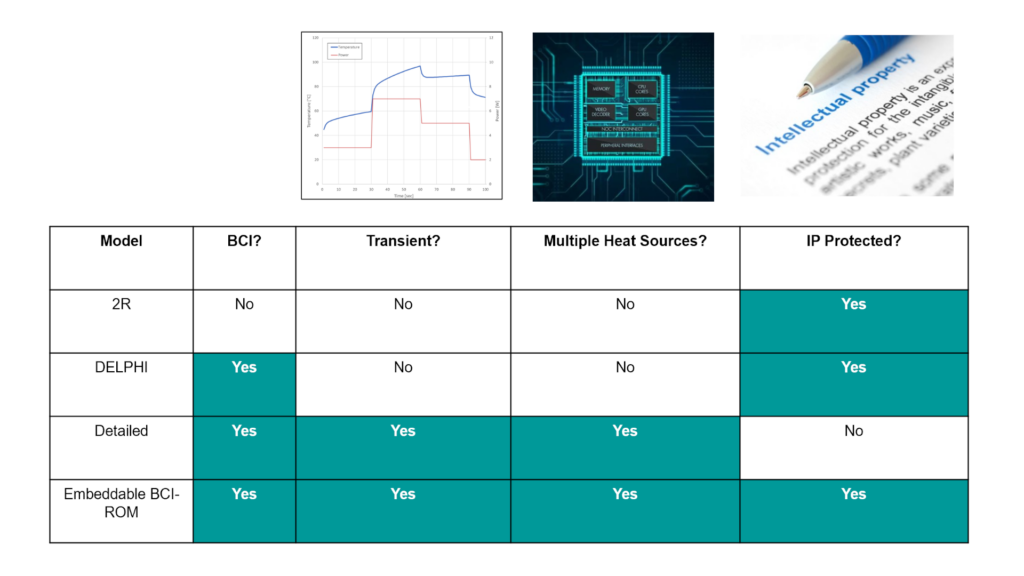

- Transient thermal modeling considering power variations is required in many cases to evaluate operating scenarios

- Full detailed thermal models for 3D analysis contain physical geometry and material properties inside of a package which are Intellectual Property (IP) sensitive.

- Standardized compact thermal models (CTMs), such as 2-Resistor and DELPHI, do not support transient simulations or multiple heat sources

Barriers to model data exchange, typical work arounds and analysis fidelity risks:

IP protection and legal considerations create barriers to thermal model exchange in the electronics supply chain. Semiconductor OEMs will sometimes rely on non-disclosure agreements in order to share detailed thermal models with their key clients, however that is not always scalable to supply to large numbers of clients and does not prevent accidental disclosure of IP. Many companies refuse to share detailed models at all.

In a high proportion of typical analysis processes, thermal engineers who are modeling packages in systems are struggling to secure suitably accurate 3D package thermal models within project time constraints. They may source a detailed thermal model from an OEM by request, they may take a simplified modeling approach, or they may create their own detailed thermal model or compact thermal model with only limited information they can source. This results in delays and often introduces inaccuracy risks. Inaccuracy leads to overdesign and higher cost, or under design leading to reliability risks.

What is an Embeddable BCI-ROM? How is it used in 3D CFD thermal analysis?

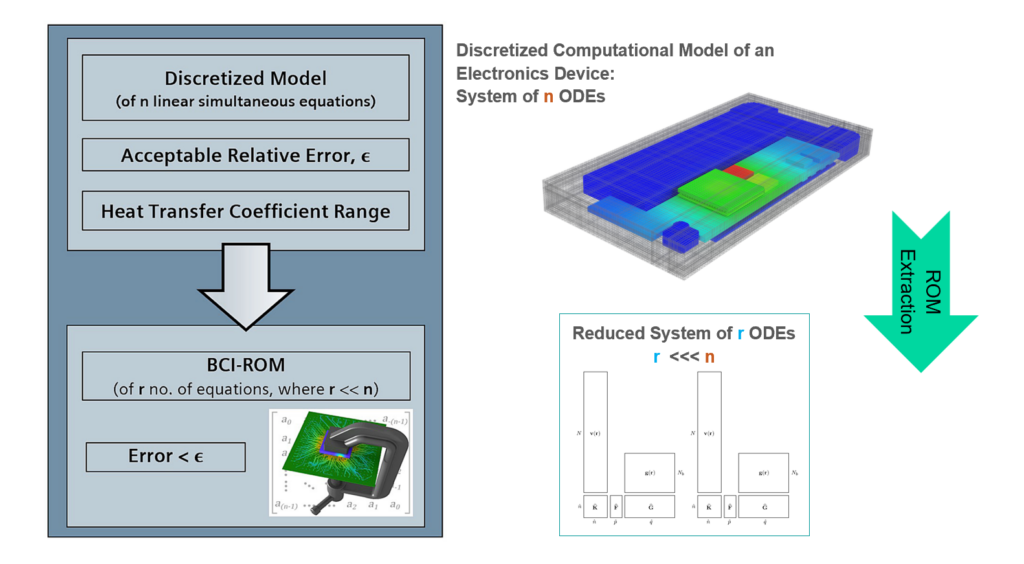

Embeddable BCI-ROM = Embeddable Boundary Condition Independent Reduced Order Model.

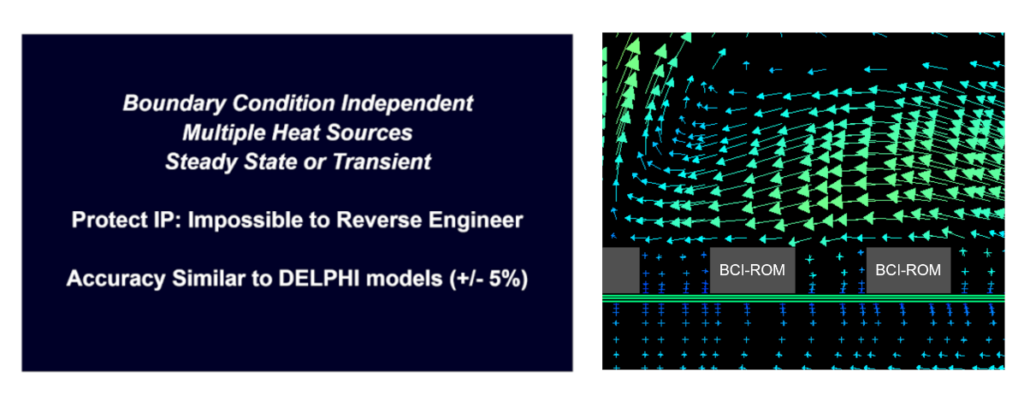

The BCI part of an Embeddable BCI-ROM means that it can be used in any thermal environment which is advantageous when considering package thermal modeling for integration in different systems. A model is BCI if it predicts temperature in space and time with accuracy regardless of the thermal environment in which it is placed. It will function correctly in natural convection, forced convection, with or without a heat sink, etc.

The BCI-ROM technology is an extension of the FAst Novel Thermal Analysis Simulation Tool for Integrated Circuits (FANTASTIC) method pioneered by Professor Lorenzo Codecasa from Politecnico di Milano, Italy. Publications generally describe the method are included in references at the base of this article and in a recent blog focused on the origins of reduced order thermal models for 3D CFD analysis.

This method has several valuable characteristics:

1) accuracy is mathematically assured by the FANTASTIC method. The required accuracy is set by the user as the acceptable relative error when the Embeddable BCI-ROM is extracted. The heat transfer coefficient (HTC) range is set by the user on extraction.

2) accuracy is ensured in both space and time, offering full support for transient applications

3) the method supports any number of heat sources, offering full support for modern package architectures with multiple chips, and for higher fidelity modeling approaches containing multiple power dissipation zones on individual chips.

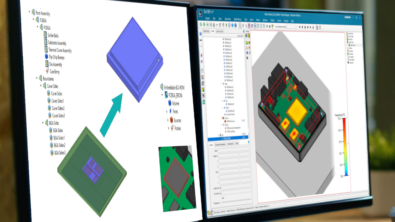

The new Embeddable BCI-ROM is a 3D analysis ready type of reduced order model based on BCI-ROM extraction methods with additional detail assigned and calculations made during generation to reduce thousands of objects in a detailed thermal mode down to a single 3D Smart Part object.

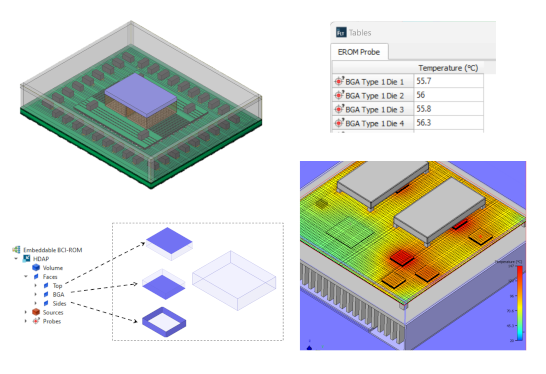

The Embeddable BCI-ROM imports into a 3D CFD thermal analysis as a single Simcenter Flotherm Smart Part. The Smart Part object faces interact with solid bodies (e.g board mounting or a heatsink placed on it), with the surrounding airflow, and with the surroundings via thermal radiation. Based on how the Embeddable BCI-ROM is configured, any power sources set can be assigned powers in the 3D thermal analysis and thermal results for surface temperature and at key internal locations set as probes during Embeddable BCI-ROM extraction can be viewed as tables or charts. Importantly, 3D geometry and results internally within the package are not accessible or possible to reverse engineer.

For more background on the historical development of package thermal models, BCI-ROM methods and Embeddable BCI-ROM approach motivation, including industry and academic research collaboration – please see this blog by Robin Bornoff “Embeddable BCI-ROMs, Taking Electronic Thermal Simulation to the Next Level, a Personal Perspective“.

How do Embeddable BCI-ROM reduced order thermal models help electronics thermal design?

Semiconductor OEMs and package providers can now supply a model to their clients that is accurate for 3D thermal analysis without the risk of exposing sensitive IP and the model can be used for 3D transient thermal analysis and support multiple heat source complex package types. This eliminates IP protection concerns. With increasing availability of Embeddable BCI-ROMs – this also provides an accurate solution to engineers who spend significant time developing their own CTMs or detailed models with limited information, shortening their workflow. Logically, improving accurate 3D system level thermal modeling through using Embeddable BCI-ROMs for package thermal models will result in more reliable electronics products and shortened design cycles.

Here is a comparison of available options for package thermal modeling assessing suitability against 4 criteria.

Only Embeddable BCI-ROM models fulfill all 4 criteria for 3D thermal analysis in a secure transportable form.

Video Demo: Embeddable BCI-ROM workflow in Simcenter Flotherm software

Watch the following video on creating an Embeddable BCI-ROM (as an author persona) and then using it mounted on a PCB in an enclosure within a system level Simenter Flotherm model (as consumer persona).

How do you easily create a detailed thermal model before generating an Embeddable BCI-ROM?

Simcenter Flotherm Package Creator, in Simcenter Flotherm XT, helps engineers easily create accurate detailed, 3D CAD based, electronics chip package thermal models in minutes for direct use in PCB & system level electronics cooling simulation. Engineers can now create detailed model geometry from popular package families in Package Creator and then export it directly to Simcenter Flotherm to create the detailed model as the basis for exporting an Embeddable BCI-ROM. The following video includes the creation of the Flip Chip BGA processor package used in the demonstration video above.

Note: Package Creator is available in Simcenter Flotherm XT. Flexx licensing is available to allow access to Simcenter Flotherm or Simcenter Flotherm XT.

Comparing Embeddable BCI-ROM accuracy to two-resistor (2R), DELPHI and detailed thermal models

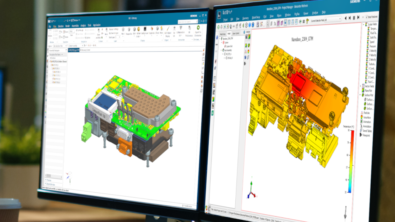

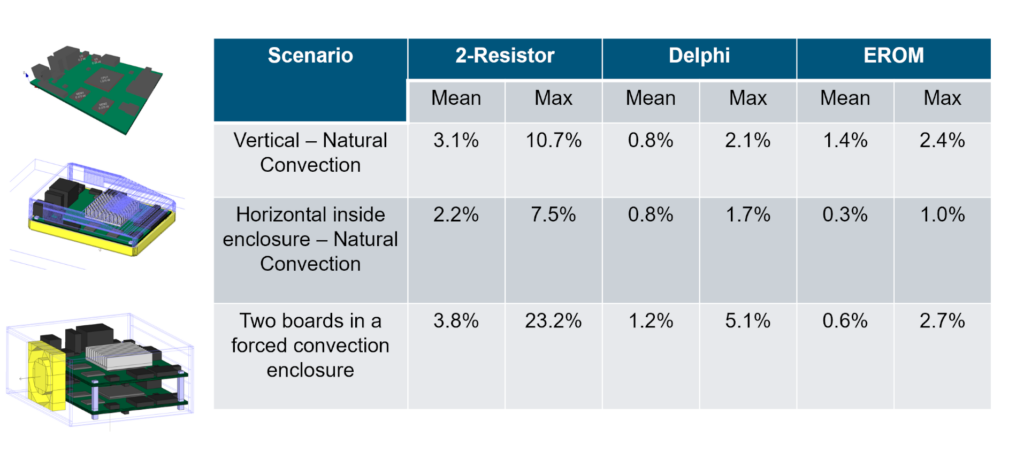

Above I summarized the differences and main benefits of Embeddable BCI-ROMs compared to standard compact thermal models and detailed thermal models in a table for 4 criteria. To illustrate accuracy in steady state 3 different system model examples were recently analyzed. A number of IC packages in each model were originally modeled using detailed model type, then the same steady state simulations were performed with the IC packages modeled in two-resistor (2R) , DELPHI and finally with Embeddable BCI-ROM models. The table below shows the comparative accuracy by looking at maximum error variation compared to detailed thermal model results.

In the table, you can observe that the Embedded BCI-ROM is well under 5% error compared to the detailed thermal model results, offering an accuracy level comparable to the standard DELPHI model approach or better. This is achieved while supporting options for multiple heat sources and transient simulations, making Embeddable BCI-ROMs a substantial upgrade on the DELPHI approach.

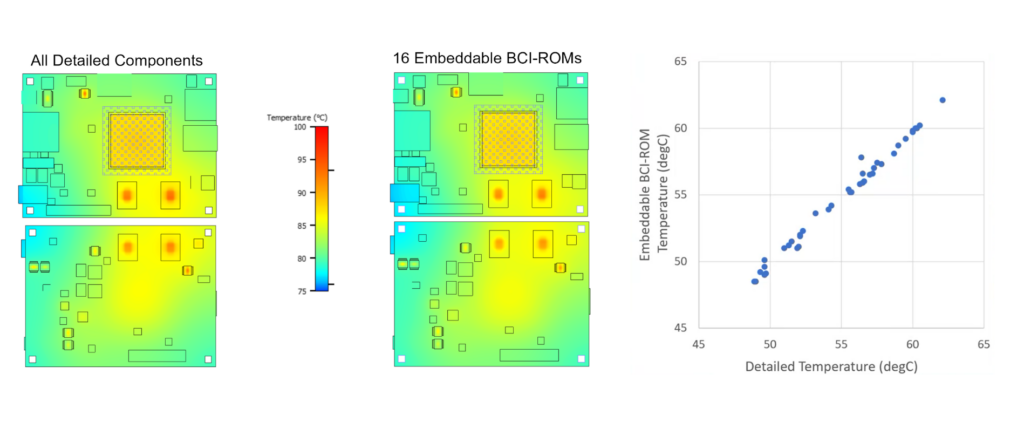

Taking a closer look at steady state comparison of detailed thermal models and Embeddable BCI-ROMs, let’s consider a model of a PCB that is horizontally mounted in an enclosure. There is a heat sink on an FCBGA processor considered. Cooling is by natural convection only.

Below is a plan view of the same PCB showing the top and bottom of the board. Visually from the surface temperatures and the junction temperature plots comparison (right), there is close accuracy and minimal difference in the results for the packages. Looking at the plot comparing accuracy of the component package models, the maximum difference is 2.5% of an outlier and the average is <0.9 %. This strongly demonstrates that acceptable accuracy level with complete confidentiality is possible with Embeddable BCI-ROMs.

In comparing Embeddable BCI-ROMs to detailed thermal models, for over 140+ detailed thermal models compared to, the majority {96%} of the components junction temperature results were within the 5% of the detailed component results. This is comparable or even better in many instances than detailed models compared to DELPHI models.

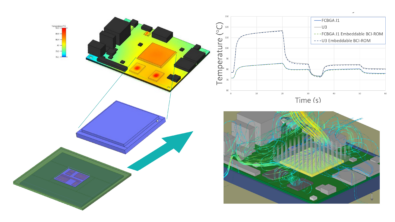

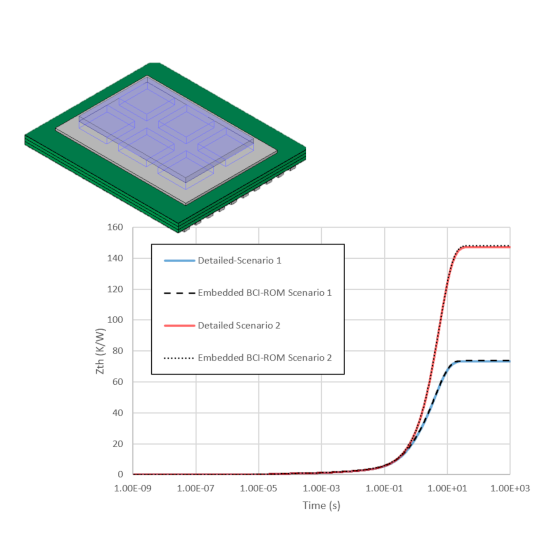

Transient thermal analysis comparison using Embeddable BCI-ROM

Transient thermal simulation is increasingly a requirement to prove design thermal performance and reliability for given operating power modes and conditions that a product is exposed to during use intended.

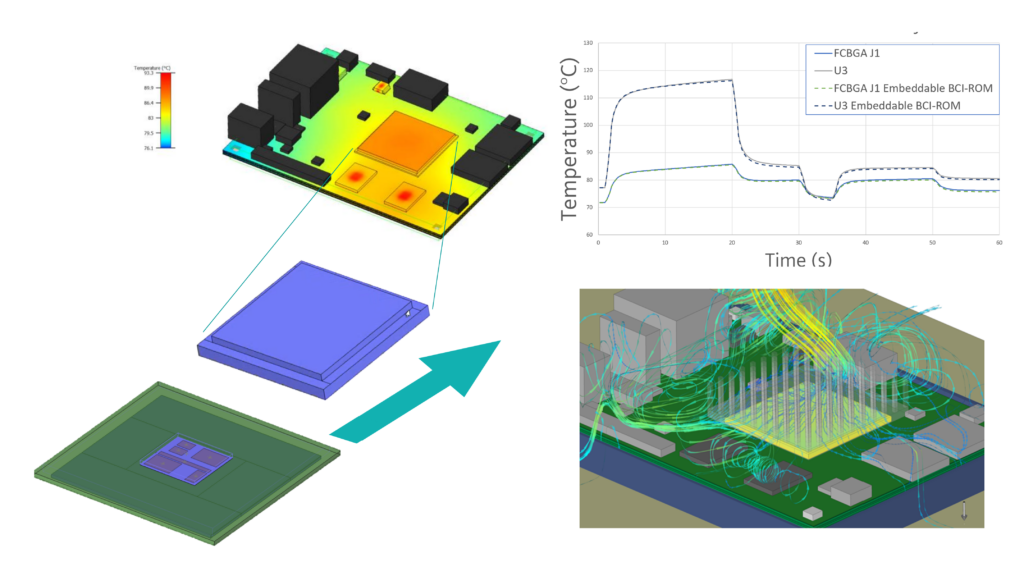

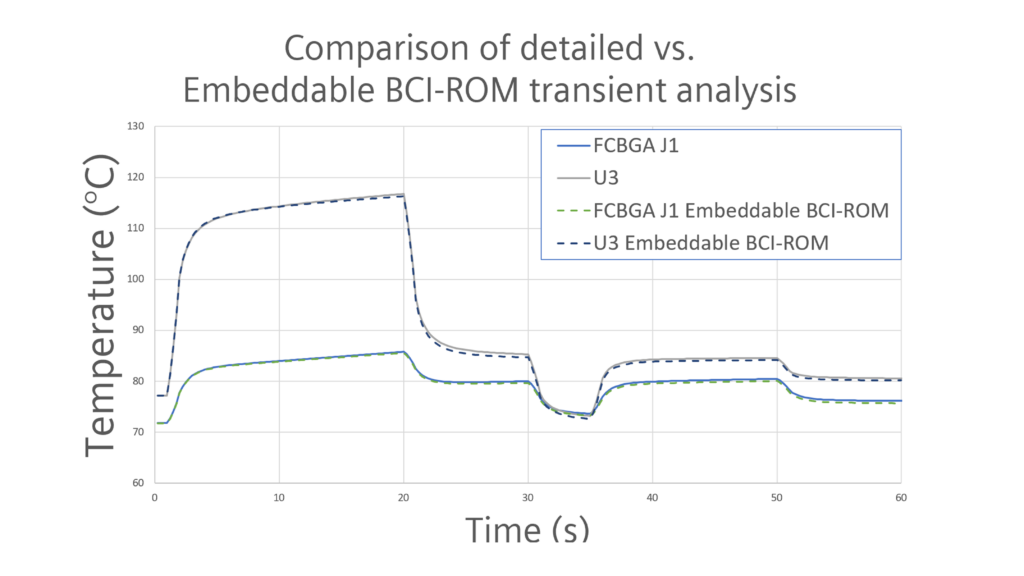

Using the same board in enclosure example, a transient simulation case was set up. A transient power profile is applied to several components. 2 components of specific interest are investigated the processor (named FCBGA) and (named U3). One version of the model was simulated with detailed models and one using Embeddable BCI-ROMs.

The temperature results for the components of interest in the 2 models are below in a combined plot where detailed thermal models are compared to Embeddable BCI-ROMs:

There minimal variation in the results, illustrating very acceptable transient temperature predictions results, while providing complete package internal geometry confidentiality, are achievable with Embeddable BCI-ROMs.

What are other examples of Embeddable BCI-ROM thermal modeling applications?

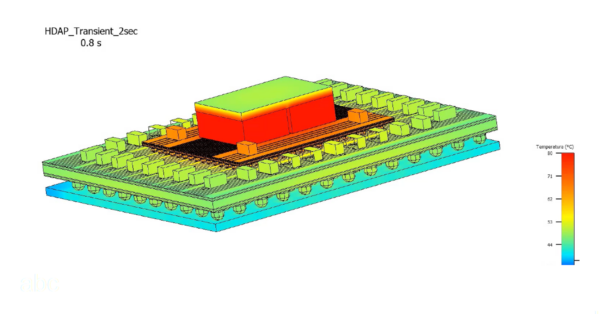

High Density Advance Package (HDAP)

Chiplet

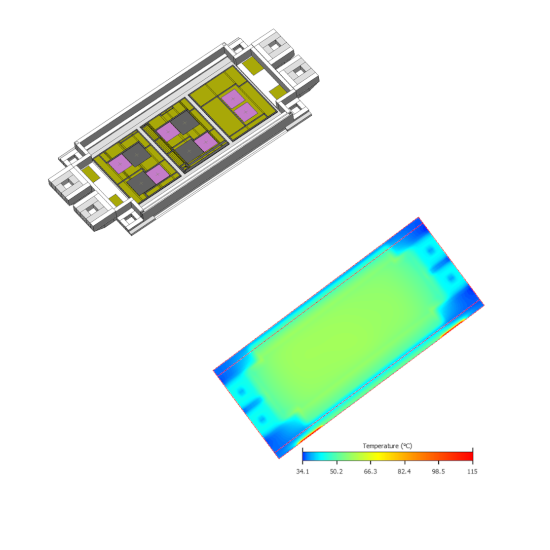

Power Electronics – IGBT module

This blog mentions a few package modeling applications to illustrate the wide range of applications you can apply Embeddable BCI-ROM modeling to. Please contact us with your questions on the suitability for your application, whether you work for a semiconductor company or you work in thermal design , integrating packages into an electronics product. You can explore personal insights on Embeddable BCI-ROM development and the history of package thermal model types in this additional blog by Robin Bornoff.

What do customers say about Embeddable BCI-ROM technology?

“Embeddable BCI-ROM is a great way to share our thermal models with our customers. It has several key features: easy generation, confidentiality, low error rate, and suitability for steady-state and transient applications,”

– Jimmy Lin, Technical Manager, MediaTek Inc.

This quote is part of the 2024 news article: Siemens brings secure thermal digital twin technology to the electronics supply chain

What are key modeling considerations? Where can I find more guidance?

For users: There are guideline documents for creating and using Embeddable BCI-ROMs to ensure accuracy and stability. This takes the form of a validation document and best practices guide on Siemens Support Center that you can download.

Please read the in-depth background on package thermal modeling development and industry and academic collaboration over years that has resulted in Embeddable BCI-ROM technology being available in this additional blog.

If you are not using Simcenter Flotherm today or do not yet have access to the BCI-ROM module – please contact Siemens Digital Industries Software now to request a technical consultation on your use case.

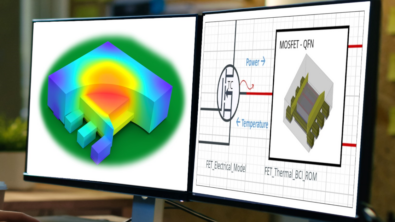

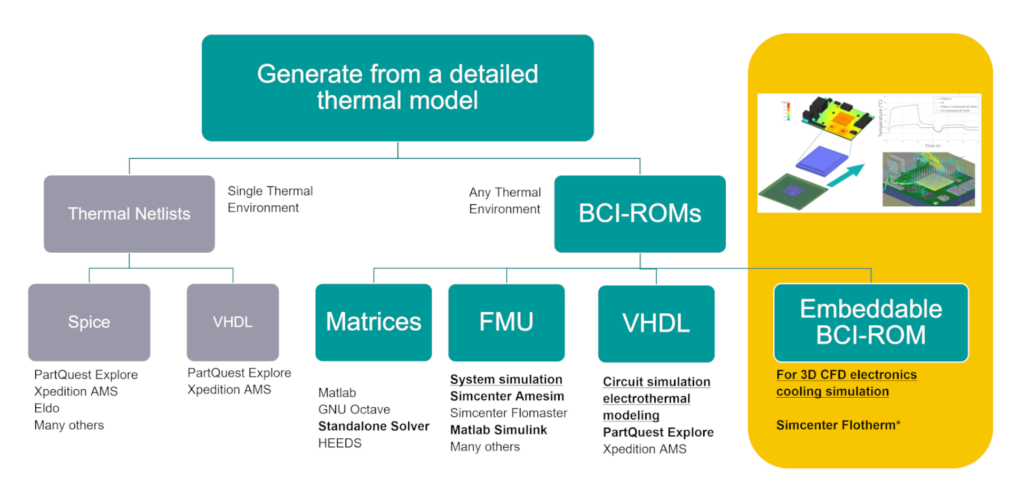

What other types of Boundary Condition Independent Reduced Order Models (BCI-ROM) are there?

Embeddable BCI-ROM in Simcenter Flotherm joins the other types of BCI-ROM that exist to support fast, accurate thermal modeling in different modeling environments leveraging their boundary condition independent nature. These other BCI-ROMs support electrothermal modeling in separate circuit simulation , 1D system modeling software tools or standalone matrices solution.

Please note: Simcenter Flotherm is currently the only tool supporting Embeddable BCI-ROM model generation and use as of Simcenter Flotherm 2310. All other BCI-ROM formats for matrices, circuit simulation and system simulation use are possible to generate from Simcenter Flotherm, Simcenter FLOEFD, and Simcenter Fotherm XT.

Siemens Digital Industries Software is committed to leading the sector of electronics thermal simulation software technologies for 3D CFD simulation, electro-thermal circuit simulation and system simulation – supporting clients as they develop a thermal digital twin to ensure product reliability and pursue lowest cost, fastest time to market goals.

References:

- L Codecasa, V d’Alessandro, A Magnani, N Rinaldi, PJ Zampardi, “Fast novel thermal analysis simulation tool for integrated circuits (FANTASTIC)”, 20th International Workshop on Thermal Investigations of ICs and Systems (THERMINIC) article 6972507 United Kingdom, 2014.