Enjoy tuning your simulations? LOOK AWAY!

We live in the day of automatic. It seems like every day there is a new task that can be handled automatically. Smart thermostats make sure the house is comfortable when returning from work. Home lighting themes customize an ambiance based on who is home and the time of day. Automatic delivery of your household goods ensures you’re never out of toothpaste. The automatic potato peeler saves you from having to peel potatoes by hand…ok, well maybe that’s going too far. The point is that technology is great for taking care of tasks based on rules or schedules so that you can focus on more important things.

The pervasiveness of automation makes it even more annoying if once you get to work and sit down to run a simulation, you need to fine-tune settings and fiddle with parameters. Or, even worse, if it’s necessary to babysit a challenging case to make sure it runs as expected. Now, there likely was a time in your professional life when diving head-first into the details of flow solvers was interesting and, dare I say, fun. I know it was for me and if you’re reading this blog, then I bet it was for you too 😊. In fact, when it’s possible to set aside time to dig into some new and different case, it’s still fun to research the best methods to use and how to apply them.

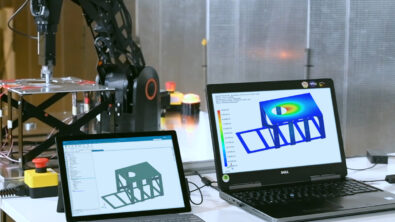

Daily work is different, though. Timelines are always shorter. More data is always needed. Your attention is always split between half-a-dozen urgent tasks, not to mention the ever-growing list of work that you keep meaning to get to once you have time. Forget tuning simulation methods for each case, you need to set up the case once knowing that it will run quickly, reliably and give accurate answers.

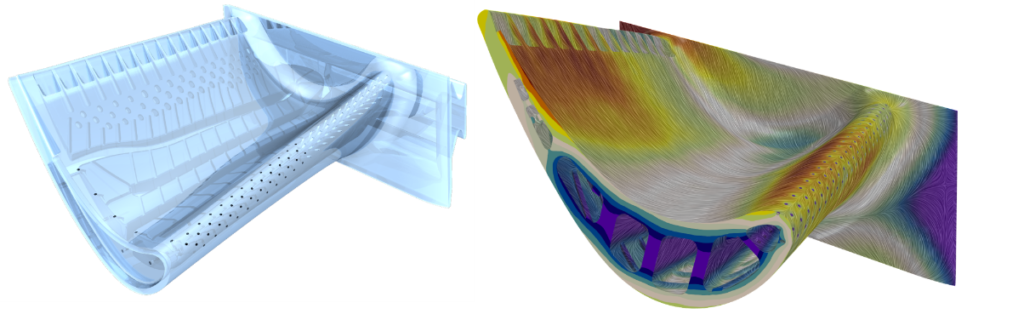

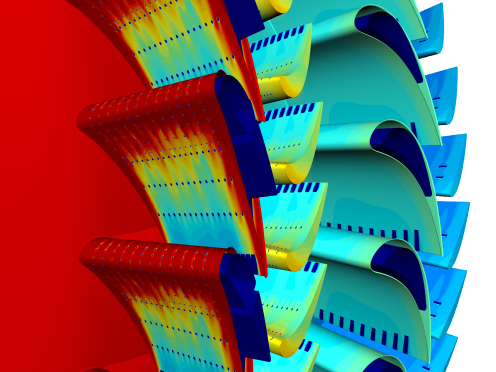

Simcenter STAR-CCM+ 2020.1 has that need squarely in mind. Among the many capabilities that this release brings, one that I’m most excited about is the automatic coupled solver control. The coupled solver is the go-to solver for flow and heat transfer analysis for many application areas, including my focus area of turbomachinery. The solver provides extremely accurate results and is great for very large grids, which are often needed for high-fidelity flow and heat transfer analysis of complex turbine blades. However, large and complex cases often required prior knowledge and expertise to achieve fast convergence.

The coupled solver received two sets of improvements that work together to dramatically improve workflow and turnaround time for both the cases that need to run automatically out of the box and the cases where you want specific control of settings: a reorganization of settings and an automatic solver control method.

Simplified Setup

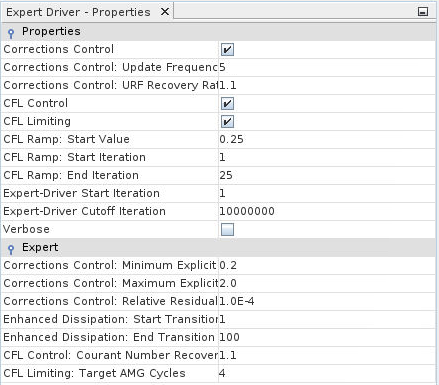

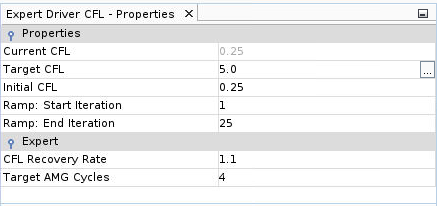

The organization and presentation of solver settings has been dramatically simplified so that it’s much easier to apply settings. As an example, check the comparison below on how the setup of the “Expert Driver” option has been simplified.

Simcenter STAR-CCM+ 2019.3

Simcenter STAR-CCM+ 2020.1

This upgrade means that if you want to dig into specific settings, that’s now much easier to do.

Faster Convergence

The advancement that’s even more exciting about is the Auto-magic CFL control option. Ok fine, the Automatic option. But it really does feel like magic.

CFL is one of the very important solver parameters for achieving a stable run and fast convergence. At its most basic level, higher CFL will give faster convergence and lower CFL will give a more stable simulation. Wouldn’t it be great if the solver could automatically determine the optimal value of CFL for fast AND stable convergence? That happens with the new Automatic option.

A companion parameter to CFL is the explicit relaxation. This too has a similar tradeoff between stability and speed. The new Line Search is an intelligent method that periodically checks to see if the explicit relaxation factor needs to be changed to achieve optimal stability and speed.

With these two automatic settings enabled, it’s possible to do away with solver tuning and simply send simulations off to run knowing that you will get a fast, stable and accurate solution.

The Test Case

To test this out, I went way back and dug out the case from a 2015 IGTI paper that Ritu Eshcol wrote. (side note: check out Ritu’s excellent blog on Adaptive Mesh Refinement, another excellent capability released in Simcenter STAR-CCM+ 2020.1.) That paper focused on comparing steady and unsteady solutions for the two-stage NASA Energy Efficient Engine.

For my test, I took the steady simulation file from 2015, loaded it into Simcenter STAR-CCM+ 2020.1, turned on the two automatic solver options and ran the solution from scratch.

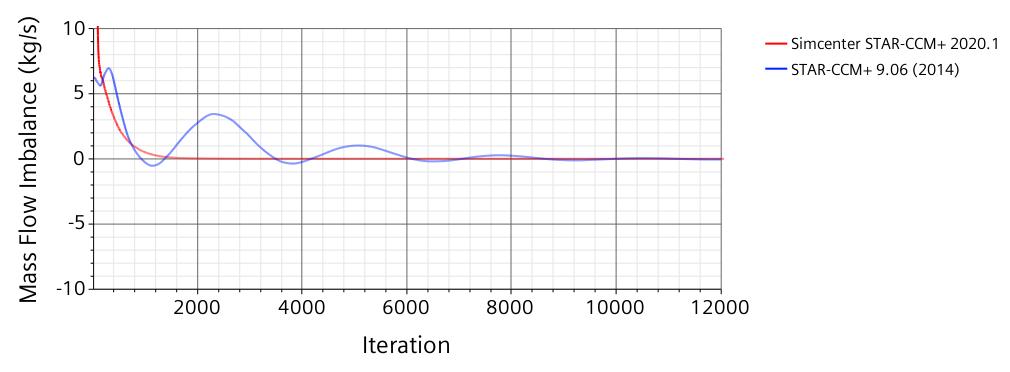

One common method for determining when a simulation is converged is to monitor the mass flow imbalance. Once the mass flow imbalance has reached zero, the simulation can be stopped. The chart below shows that for the paper, the case needed 12,000 iterations to converge, and with the new automatic controls (as well as many other solver advancements over the last 6 years), the case converges in less than 2,000 iterations!

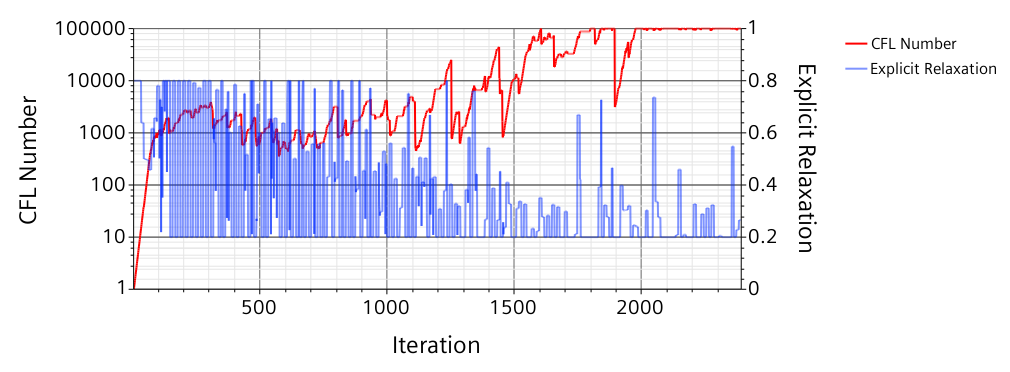

How can it be that much faster? It starts to make sense if we look at how much work these automatic controls are doing. The plot below shows that early in the simulation, both parameters can be quite high, but are often adjusted (automatically) to maintain stability. Once the solution starts to settle in, less adjustment is needed, and the CFL skyrockets. Yes, you are reading the graph right, it’s running at a CFL of 100,000!

Out-of-the box, with no solver tuning, I sent the simulation off to run and went home. When I opened the sim file the next morning, I found that my case quickly converged to provide an accurate flow solution. Now that’s a workflow I can get behind!

While I think we all can agree that turbomachinery is the most interesting application area, check out this blog showing that this dramatic improvement is observed across a wide variety of application areas.

Go give it a try, it’s ready and waiting for you now! See just how quickly and easily you can setup and run your simulations.

Comments

Comments are closed.