Inocean Streamlines Simulation Process with NX

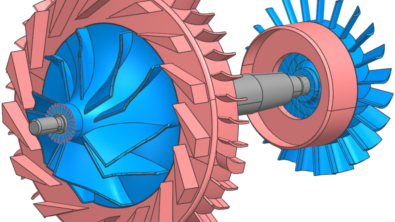

Offshore oil vessels are massive, and with the freight they carry, there’s no room for error. Oil spills can be catastrophic, so it’s important the companies that produce these vessels such as Inocean understand how they will perform. However, their size makes them expensive and time-consuming to prototype.

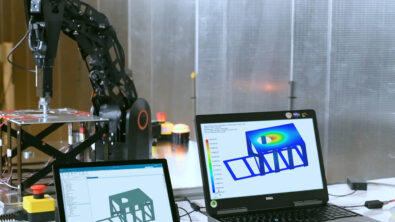

That’s why Inocean uses simulation. They perform non-linear structural analysis with NX Nastran to understand potential ship collisions, for example. NX allows them to reduce their number of CAE tools, which saves them money and increases their team’s productivity. Their simulation process is now streamlined thanks to NX.

Challenges:

Develop special naval solutions for the North Sea and beyond

Integrate complex construction tasks across operations

Combine different construction elements while meeting schedules/due dates

Keys To Success:

Use NX to advance innovation and accelerate turnaround of highly advanced offshore products and services

Collaborate effectively with international divisions, partners and customers

Implement change management process seamlessly across operations

Results:

Easy, fast and secure implementation of product changes, corrections and updates in real time

More agile workforce across locations

Higher quality and greater innovation built into deliverables

Improved best practices via integrated digital product development platform, with significant error reduction throughout operations

New business

Industry:

Marine

Client’s Primary Business:

Inocean offers design and engineering services to the maritime industry worldwide. Its core competence is engineering studies and project execution for offshore platforms and marine structures across the oil, gas and renewable industries.

Solutions/Services:

Client Location:

Oslo

Norway

Want to learn more? Read the full Inocean case study here!