Integrated CAD and CAE fasteners with NX Join and Simcenter 3D

Integrated CAD and CAE builds relationships

NX Join reduces the time needed to place and define fasteners and hardware. NX Join targets users of fasteners in CAD models. It enables faster placement of locations and establishes relationships with parent parts. Thus providing additional intelligence to the Join features in the model and integrating CAD and CAF further.

Read more about NX Join here.

The integration of NX join into Simcenter 3D 2206 makes it possible to dramatically speed up the design and analysis process for connecting components, such as spot welds and rivets, that are in assemblies.

Creating a finite element model from a complex CAD assembly requires many steps, including modeling the connections between components. Complex assemblies may require hundreds or thousands of connections. The process for defining connections across design and analysis typically involves multiple software tools and/or customized code. In the past, there was no support for the communication of connections from the CAD design to the CAE analysis, in a smooth out-of-the-box function, in off-the-shelf software – until now.

Reducing the number of steps

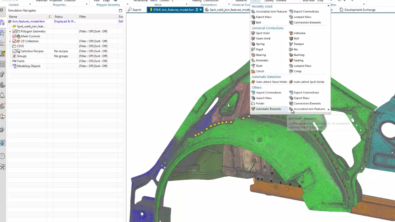

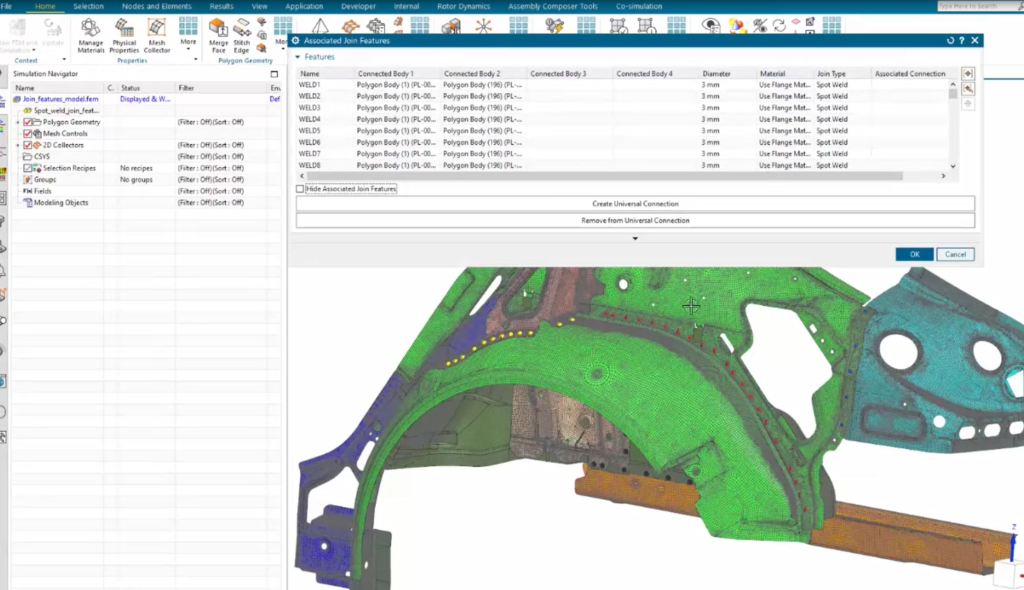

Simcenter 3D can automatically create connection definitions from NX Join features, via a new command in the Universal Connection suite of tools. The new command is “Associated Join Features,” and it finds the NX Join features from the associated CAD model and creates the corresponding connection topology definitions in the FE model.

The new command will present all the NX Join features in table form. From here, you can create universal connections from all the NX Join features in one go. Alternatively, you can pick and choose which Join features to inherit into Universal connections.

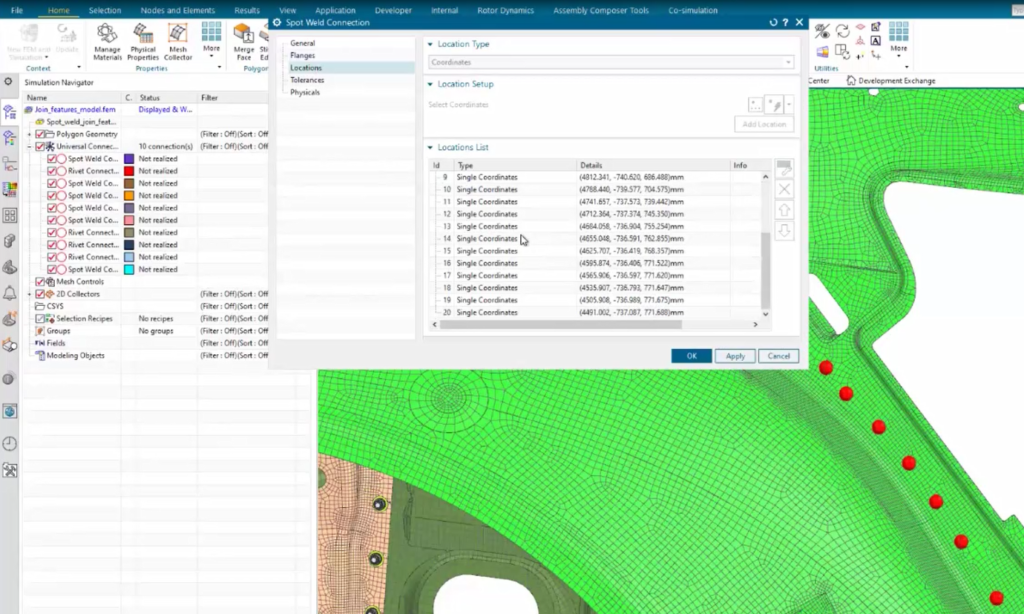

When you create Connections in NX Join features they appear as normal Universal Connections that you can edit as needed. Additional options are provided to add or remove NX Join features in the Connection UI.

You can make changes to the original NX Join features in the NX CAD model, that propagate to the FEM model as required. This is due to the associative nature between NX Join features and Universal Connections in Simcenter 3D. After defining this connection relationship, the connections in the FE model will track the NX Join features and will update the FE connections as needed.

What these tools can do for you

These tools make it possible to have a single source definition for the connections of an assembly. This ensures the smooth transfer of this information from your CAD to your analysis. The associative relationship between the CAD and CAE connection definition speeds up the initial creation of the connections through the process and provides a quick turnaround when changes are made to connections in the source model. These tools greatly reduce the chance of errors due to CAD and CAE models being out of synch. This leads to increased confidence in the manufacture of products as well as their performance in the field.