Introducing Simcenter 3D Low Frequency Electromagnetics 2019.2

Simcenter 3D Low Frequency Electromagnetics (Low Frequency EM) is part of Simcenter 3D Electromagnetics, which also includes high frequency Electromagnetics.

Simcenter 3D Low Frequency EM offers insight into the performance of electromechanical and energy conversion devices. These include utility and electronic transformers, motors, generators, linear machines (e.g. maglev), actuators, shakers, speakers, solenoids, relays, circuit breakers, induction heating, bus bars, winding systems, ignition coils, etc.

It is based on Simcenter MAGNET that is built on several decades of expertise. In addition, it leverages the multidiscipline CAE capabilities, and being geometry-centric, leverages as well, the CAD modeling of Simcenter 3D, which is built-on the NX foundation. Let us now look at some of its capabilities.

Extending Multidiscipline Analysis

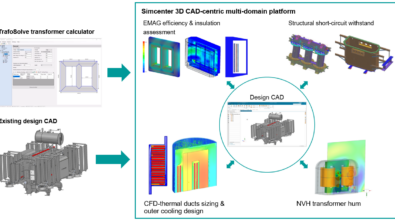

The embedding of Simcenter MAGNET in Simcenter 3D extends the latter analysis  Figure 1: Simcenter 3D CAD modeling interfacecapabilities to cover low-frequency EM performance in addition to the high-frequency EM, NVH, structural integrity, durability, and thermal modeling disciplines in one platform, from the same model.

Figure 1: Simcenter 3D CAD modeling interfacecapabilities to cover low-frequency EM performance in addition to the high-frequency EM, NVH, structural integrity, durability, and thermal modeling disciplines in one platform, from the same model.

This will permit the holistic analysis of electromechanical and energy conversion devices. The specific benefits include:

- Leveraging Simcenter 3D CAD capabilities to eliminate CAD bottlenecks, by supporting the import of any CAD format, modeling of complex devices, defeaturing, tracking of modifications, etc.

- Support for multiple disciplines in one integrated platform.

Analysis and Solution Types

Simcenter 3D Low Frequency EM supports both 2D (translational and axisymmetric) and 3D electromagnetic analyses, whose solution type can be static, harmonic and transient with motion capability. It has an integrated 1D circuit tool that supports the customization of current and voltage sources. Its extensive EM material library eases the initial EM model setup. The materials are customizable to account for variation in properties resulting in realistic simulations.

These electromagnetic and thermal analysis modules can simulate steady-state and transient electromagnetic and temperature fields. Some of the resulting user benefits are:

- Support for linear, rotary, 6 degrees of freedom motion and multiple moving parts, supporting the simulation of complex motion like magnetic levitation, EM catapults, and robotic joints.

- Increasing the efficiency and reliability of electromechanical devices by accurately considering both the EM and thermal aspects.

- Validating models at extreme operating and fault conditions for reliability analysis (torque, efficiency, demagnetization, temperature hotspots, etc).

- Fast solves, that are adapted and optimized for applications, e.g., transformer analysis that uses the time-harmonic solver and unary binary conditions meant to reduce the solving time.

Smart Boundary Conditions

Large models like power transformers, wind and hydro generators and heavy industry motors, are not only large but have very thin parts relative to the model’s size. This  Figure 2: Unary (SIBC) and binary boundary conditions applied to a partial transformer modellikely results in large simulation models. In addition to structured meshing, Simcenter Low Frequency EM offers binary and unary boundary conditions. Unary boundaries negate the need for a volume mesh, which significantly reduces the solution time. An example is the surface impedance boundary condition (SIBC) that is applied to conductive permeable parts, like the transformer tank, clamps, and other mechanical support structures. Binary boundary conditions permit the use of partial models.

Figure 2: Unary (SIBC) and binary boundary conditions applied to a partial transformer modellikely results in large simulation models. In addition to structured meshing, Simcenter Low Frequency EM offers binary and unary boundary conditions. Unary boundaries negate the need for a volume mesh, which significantly reduces the solution time. An example is the surface impedance boundary condition (SIBC) that is applied to conductive permeable parts, like the transformer tank, clamps, and other mechanical support structures. Binary boundary conditions permit the use of partial models.

Advanced Material Modelling

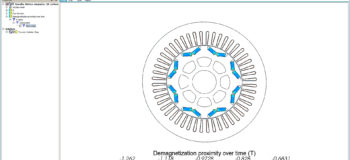

The confidence of low-frequency EM simulations is influenced by material modeling. Core nonli Figure 3: Demagnetization fields in a PM traction motornearities, temperature dependencies, demagnetization of permanent magnets, anisotropic and hysteresis core effects, conductor eddy-currents and proximity effects, should be taken into account depending on the study to balance the need for accuracy and speed. Besides the confidence in the results, this capability can be leveraged for:

Figure 3: Demagnetization fields in a PM traction motornearities, temperature dependencies, demagnetization of permanent magnets, anisotropic and hysteresis core effects, conductor eddy-currents and proximity effects, should be taken into account depending on the study to balance the need for accuracy and speed. Besides the confidence in the results, this capability can be leveraged for:

- Assessing the risk of demagnetization of permanent magnets to ensure robustness at peak or fault conditions, at elevated temperatures particular for EV/HEV traction PM motors.

- Analysis of frequency-dependent losses in winding systems such as utility and electronic

- Nonlinearity core approximation in the time-harmonic solver that is inherently linear for transformer analysis.

- The consideration of hysteresis loss during solving is critical for applications where energy balance is important like in small devices like micro, MEMs, sensors and actuators.

Therefore, electromechanical and energy conversion devices performance and reliability can be ensured by leveraging the multidiscipline CAE capabilities of Simcenter 3D, which now includes both low and high frequency electromagnetics.