Lisa Airplanes uses Femap and NX Nastran to help certify a new plane

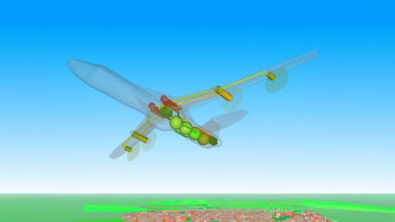

In the Savoie region of France in the French Alps, a team of enthusiasts set about inventing a new way to travel. They embarked on an ambitious and far-sighted project to create an all-terrain recreational aircraft capable of landing and taking off on land, water or snow – as close as possible to points of interest. Setting aside all preconceptions, the team at Lisa Airplanes started afresh to design a genuinely innovative plane.

A key part of the design is ailerons that lift the aircraft fuselage off the water without compromising in-flight performance, leading to the Akoya’s most striking innovation: the seafoil. Lisa Airplanes also extended the concept to snowy terrain, increasing the versatility of the aircraft. In addition to facing these steep design challenges, the engineering team also devised an ingenious system of folding wings, reducing required storage space.

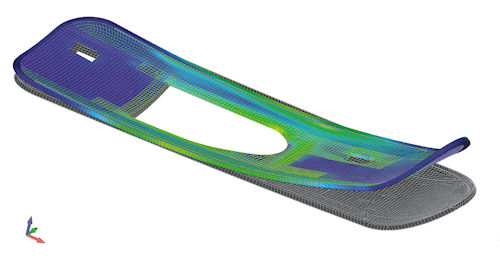

The engineering team used Femap and NX Nastran to simulate and optimize the aircraft structure, which involved a lot of composite material use, across over 200 flight cases. This also helped to expedite creation of simulation reports and obtain certification within a very short time frame, facilitating the start of serial production and delivery of first orders.

You can read or view the full case study for more information on how Lisa Airplanes leverages Femap and NX Nastran to speed up the design cycle to certification.