Road Load Data Acquisition with Gert Frans

Gert Frans works in the durability testing team for Siemens Digital Industries. He knows a thing or two about durability engineering, so we thought we might share some of his knowledge with you. Here he is, talking about road load data acquisition.

Gert, what is RLDA and how useful is it for test engineers in the automotive industry?

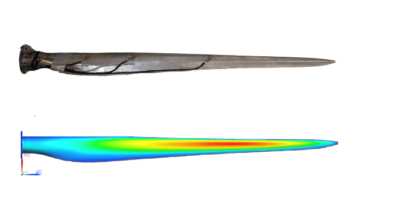

The importance of road load data acquisition, or in short ‘RLDA’, in the vehicle development phase cannot be emphasized enough. One of the most critical points in successful vehicle durability engineering is to understand how real loads act on your vehicle or equipment while it is being used by your customers. RLDA is an excellent method to accurately measure the vehicle response on these loads. Road load measurements take into account all types of essential vehicle and driving parameters, such as mass, inertia, air and rolling resistance, road characteristics, engine loads and vehicle speed. This vital load information is key input for downstream CAE and laboratory testing activities.

Why use this solution from Siemens PLM Software?

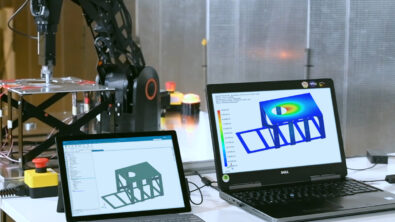

There are numerous advantages to using this system. To begin with, we know that RLDA testing teams have to deliver reliable data as fast as possible for as many vehicles as possible. With the traditional systems, this can become a stressful task. This is why many teams choose to work with advanced solutions such as the Simcenter Testlab RLDA solution. This solution is specifically made to acquire data under the most extreme testing conditions. Its universal signal conditioning allows for easy setup of various test types and it has the advantage of being compact and easy to install. It interfaces with a wide range of analog and digital sensors and offers a flexible channel count. All this helps engineers to take the correct measures from the first time. Furthermore, the system is accessible to both experienced and first-time users. No doubt, it largely contributes to a smooth and seamless durability acquisition process.

How does a typical RLDA campaign go?

A typical RLDA campaign consists of three steps. During the first setup step, the vehicle that is being tested is equipped with various sensors to measure wheel force, displacement, accelerometer, strain gauge and temperature sensors to give but few examples. The data acquisition system is configured, mounted in the vehicle, and all the sensors are checked for consistency. In the second measurement step, multichannel road load data is recorded according to the test specifications on a proving ground or public road. The final validation step focuses on sharing the results with the test and simulation teams. At this stage, all collected road load data must be checked in order to detect and correct any anomalies before transferring the data to the other teams. This is also when key discoveries are documented.

Te learn more about road load data acquisition, watch this webinar!