Membranes for separation of mixtures of gases or impurities from liquids

Fresh water is an increasingly scarce resource. Saving and recycling water makes environmental and economic sense. It is used in large quantities in the chemical and allied industries for cooling and other process requirements.

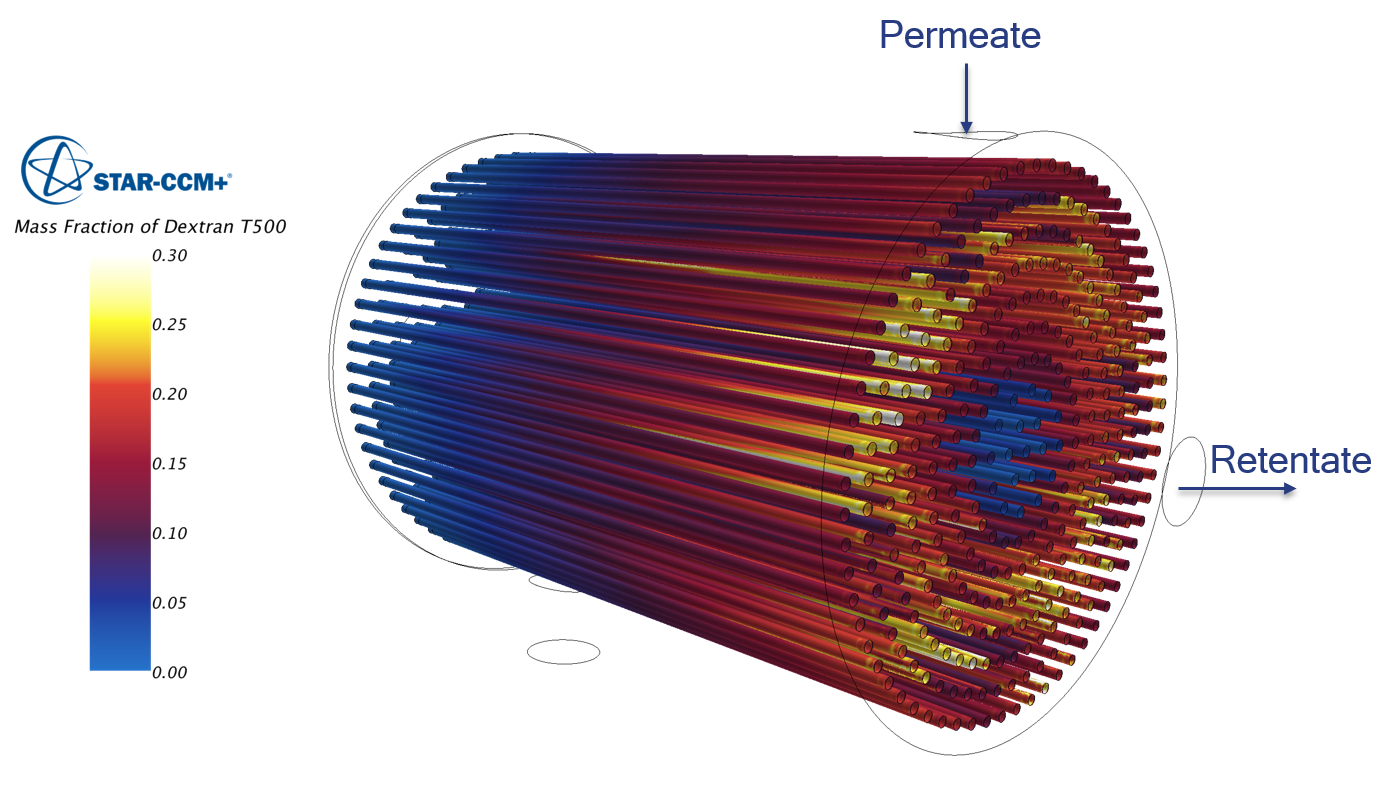

A recent new brief from EU (See here) reports the initiative on researching technologies and methods to recycle industrial water effectively. Using membrane systems for this purpose appears to be promising. Designing such a system has two main aspects: a)The membrane should have right selectivity for the substance to be removed b) The hydrodynamic design should consume low energy and provide effective and uniform hydrodynamic flow field for the membranes to be efficient in the mass transport.

Much work is being done under the E4Water program. Fluid dynamic simulation of membrane processes gives a cost effective way of testing various designs of such systems. The selective behavior of species can be incorporated in to the simulation using fugacity coefficients (gas) or osmotic pressure (liquid) concepts in such a simulation.

If you would like to learn more, please see our recent presentation on modeling hydrodynamics and separation in membrane separators from the AIChE Spring 2015 & Annual 2015 conference here .

In future, we would be looking at how rigorous design optimization can be used to achieve the hydrodynamic behavior goals for an effective performance of a membrane separator.