Products

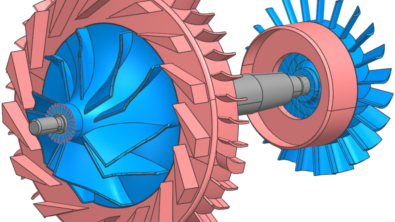

NX Case Study: Design Automation Associates, Inc.

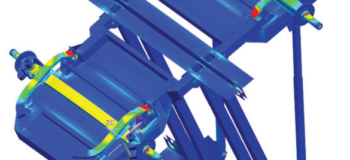

DAA redeemed itself with a key customer when it cut pre-processing time in half and reduced the mid-surfacing process by eleven hours, thus improving project turnaround time with NX CAE.

Challenges:

- Excessive analysis costs and delays

- Customer satisfaction issues

- Scheduling impact on other projects in queue

- Need to continually demonstrate technology advancement and added value to customer

Keys To Success:

- Replacing legacy analysis tool with a more advanced CAE environment

- Global Technical Access Center to speed up learning time for new simulation software

- NX CAE capabilities to decrease preprocessing time and increase analysis reliability

Results:

- Established new best practices for project schedules and budgets

- Reduced preprocessing time by 50 percent

- Increased customer satisfaction with 30 percent faster results

- Reduced mid-surfacing process from 12 hours to 1 hour

- Reduced overall project costs

Industry:

Client’s Primary Business:

Design Automation Associates, Inc. provides knowledge-based engineering and mechanical engineering consulting services.

Solutions/Services:

Read the entire case study.

Amy