Picanol: weaving wonders with LMS Samtech Samcef

Most of you probably don’t know Picanol off the top of your head. (I just happen to be familiar with the company because I live in Belgium, where flax production, linen and the weaving industry have been around even before the heyday of Renaissance Bruges.)

Today, like many classic industries in Western Europe, the Belgian weaving industry is not what it was…But even if production has moved elsewhere, Picanol has remained faithful to the Flemish Westhoek: still innovating and producing the world’s weaving machines onsite in Ieper, Belgium.

This story takes a look at how a relatively small company in the northwestern corner of Belgium has managed to put more than 130,000 weaving machines in some 2,600 weaving mills worldwide. If you think about it, there is a very good chance that the jeans you are wearing were woven on a Picanol machine. (According to Picanol, one out of three pairs!)

That is a lot of fabric, to say the least. To stay ahead in this highly competitive industry, Picanol has always believed in innovation. Innovation, technology and ongoing research and development (R&D) efforts remain crucial to the company’s international success. This is a philosophy that Picanol shares with its engineering partner, Siemens PLM Software.

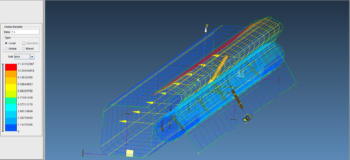

“We have worked with LMS software for years,” says Dimitri Coemelck, an R&D engineer in Picanol’s Measurement and Simulation Department. “Originally, we worked together on various research projects and one-off engineering studies. More recently, we have used LMS Samtech Samcef software to tackle some rather tricky nonlinear simulation modeling for the OptiMax series.”