Quick guide: Predicting pass-by noise earlier in the vehicle development cycle

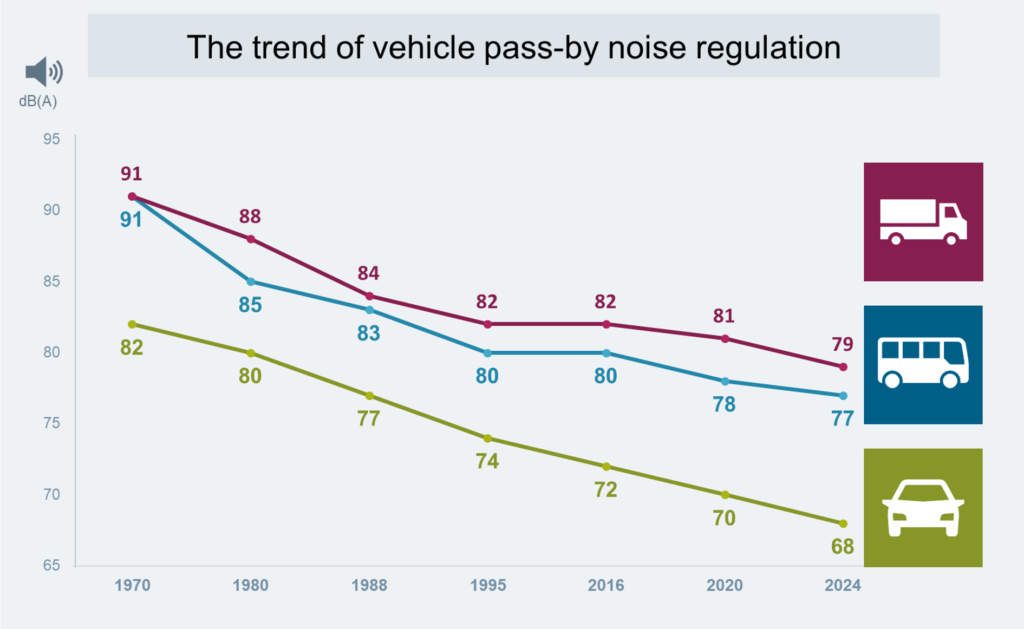

Noise pollution is an emerging issue and is becoming a hot topic around the world. More and more countries strive to improve the living environment and decreasing sound levels is one of the top priorities. The trend is obvious, especially in the transportation industry, which plays a big role in this matter. Can you believe that since the first United nations agreement, the value of the vehicle noise emission limit decreased with 14dB? And what’s more, these limits will decrease even more by 2024!

The trend of vehicle pass-by noise regulation

That means that the automotive OEMs have only few years to develop the next generation of their vehicle models with reduced noise levels. So, how the OEMs can speed up this process successfully? How can the automobile manufactures develop new models faster to comply with the new international requirements?

To answer this question, let’s first talk about some new testing methodologies available today.

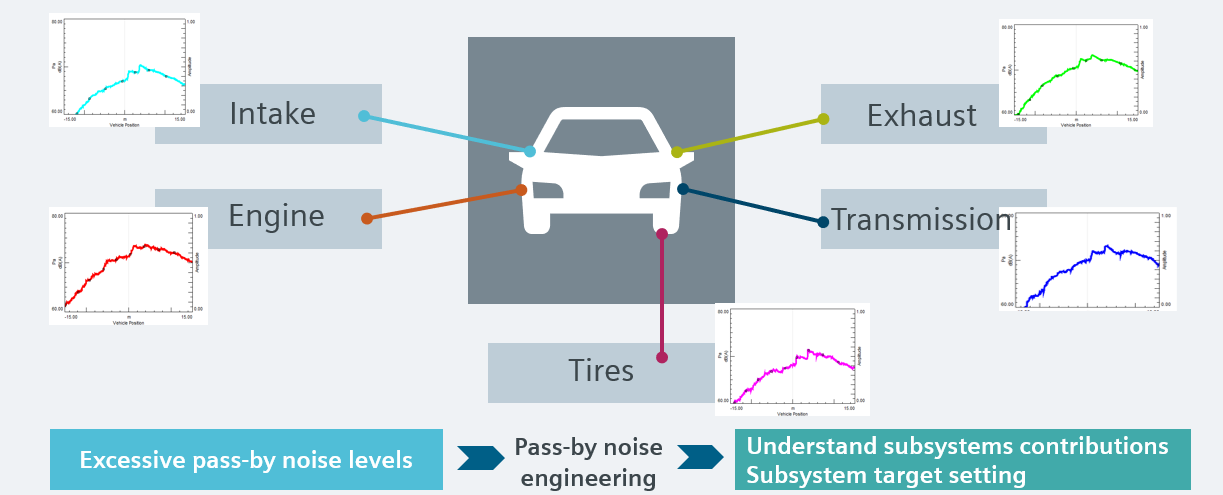

Pass-by noise engineering

Indoor pass by noise test procedure

The pass-by noise testing has been executed in open field (proving grounds / test track) since ever using dedicated test equipment. Unfortunately, this technique it is highly dependent on the weather conditions. Imagine you could execute the same test in indoor environment (semi-anechoic rooms), fully independent of the weather. What about the results? Are they equal to the exterior tests?

One innovation that the automotive industry is currently adopting, is the “indoor pass-by noise testing”. (You can read about this technique here). Defined by international standards (ISO 362-3), this methodology can now be used not only for engineering purposes, but also for homologations.

To achieve a good match between exterior and interior noise levels, the tire noise should be corrected, as this is not correctly measured indoor. The international standard also describes the methodologies, how to calculate the tire noise model and “add” it to the measured indoor pass-by noise.

It’s great that now the OEMs can use both exterior and indoor NVH tests to homologate their vehicles. Let me ask another difficult question. What happens, if at the end of your vehicle development cycle, you don’t meet official vehicle pass-by noise limits? That’s a perfect moment to talk about Pass-by Noise Engineering.

Pass-by noise testing indoors

Faster vehicle development powered by prediction of vehicle pass-by noise

For the past years, some engineering techniques were development to enable further analysis of the vehicle overall pass-by noise levels. Basically, the goal of these techniques is to separate the contributions generated by components or sub-systems. Additionally, these techniques also improve troubleshooting processes. The most complete engineering method is the Airborne Source Quantification (ASQ). The ASQ technique allows to do pass-by noise contribution analysis by separating the noise contribution for different noise sources. It also provides information about the acoustic loads of each sub-system.

The ASQ model requires a measurement of local FRF’s and acoustic noise transfer functions to identify the operational loads from nearby pressure indicator responses and propagate the loads to the various target microphones on the sides of the vehicle. Once you obtain a good ASQ virtual model, the FIR filters are constructed. This will allow you to use a time-domain synthesis of the various source contributions to each target microphone. And eventually, you can recombine the synthesized target response signals with the pass-by sound by considering the vehicle speed profile.

You can execute this technique using not only testing techniques, but also 3D simulation. If a validated finite element model of the car is available (normally used for simulation of vehicle pass-by noise radiation), you can calculate the transfer functions based on your virtual model. This step can really speed-up the full process, as measuring transfer functions can be very time-consuming.

Simcenter – Vehicle pass-by noise prediction – noise contributors

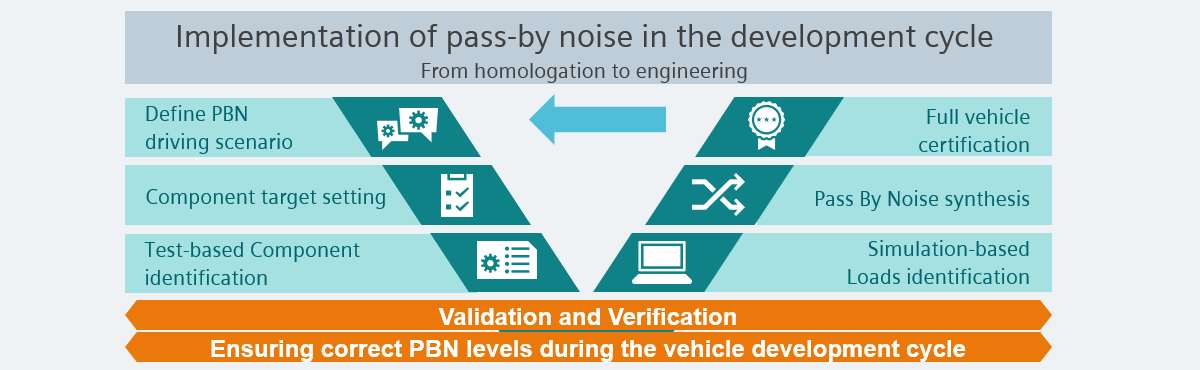

Discover the new test-based and simulation method to meet new pass-by noise requirements

Siemens Simcenter brought this engineering method to the next level. The partnership project with Daimler Trucks Germany resulted into a new method that allows to make predictions of pass-by noise levels on component level. By using the results of ASQ and testing these components in test benches, even before the integration in the full vehicle, you can define the targets already in the beginning of the development. This breakthrough methodology will set a new milestone in the relation between OEMs and suppliers. Using the potential of this approach, the targets can now be defined by component/sub-system long before the prototyping phase.

Vehicle pass-by noise engineering

Perhaps you can now think of some other great advantages of this technique? I can mention another one that is very important during a development of a new vehicle. By splitting the noise contributions by components or sub-systems, the OEMs can use these models to “simulate” several variants of vehicle configuration. This will help the responsible teams to select the best combination for the optimal final emitted sound pressure levels.

In the beginning of this article, I’ve asked what the OEMs could do to ensure their new cars will comply with the new regulation. Now that you know the latest the pass-by noise engineering techniques and its benefits, you can easily answer this question!

Learn more about pass-by noise prediction

The trend of adopting these new techniques is taking off in the automotive industry. Interestingly, it will help to shorten the development cycles, avoid delays and troubleshooting in the final stage of this cycle.

Are you interested to learn more about this topic? Please read the full paper about Pass-by Noise Prediction HERE.