Improve your measurement quality with remote data acquisition and automated data validation

Think about a challenge you face at work as a test engineer, the most annoying or the most time-consuming one. I’ll give you some time while I share mine… and yes, it is about the story which took me to remote data acquisition and automated data validation capabilities by the end.

For me, the most annoying one, by far, is noticing that the measured data is garbage after hundreds of working hours, tens of hours of travelling. Imagine you finally come to your office after a very long intercontinental trip (why do those proving grounds have to be so far from home, by the way?). You get a nice cup of coffee before you open your PC. You open the dataset, and you are with a brutal fact that your data is useless. I know, the truth is bitter, but you have to face this, go back to the same proving ground (again, why so far?) and measure again.

Or, is there no other way? You can ask your local contact to measure data for you. But, how will you trust him/her? What if the next dataset shares the same destiny with the previous one? I don’t think it would be easy then to share this news with management after losing a second-long measurement time – imagine a very long durability test measurements that you’re supposed to cover a lifetime of a product!

I know, I started quite negatively. Let’s start from scratch.

Dear test engineers,

I know a way that might help you access your measurement systems / data remotely without physically being present onsite. Independent of the physical distance, you can start/stop your measurements remotely and even validate the data quality during or just after each measurement run.

Are we good now?

Jokes aside, I was part of a team intensively working on a project where we tried to work on all these building blocks. What are those blocks?

- data acquisition system which is capable of working without human interaction

- software connects to the data acquisition hardware for different tasks such as channel setup, sensor verification, sensor calibration, online data monitoring etc.

- modem making the data acquisition hardware accessible anywhere

- server that enables secured network

- software that does advanced data quality checks

Let’s go over those blocks one-by-one.

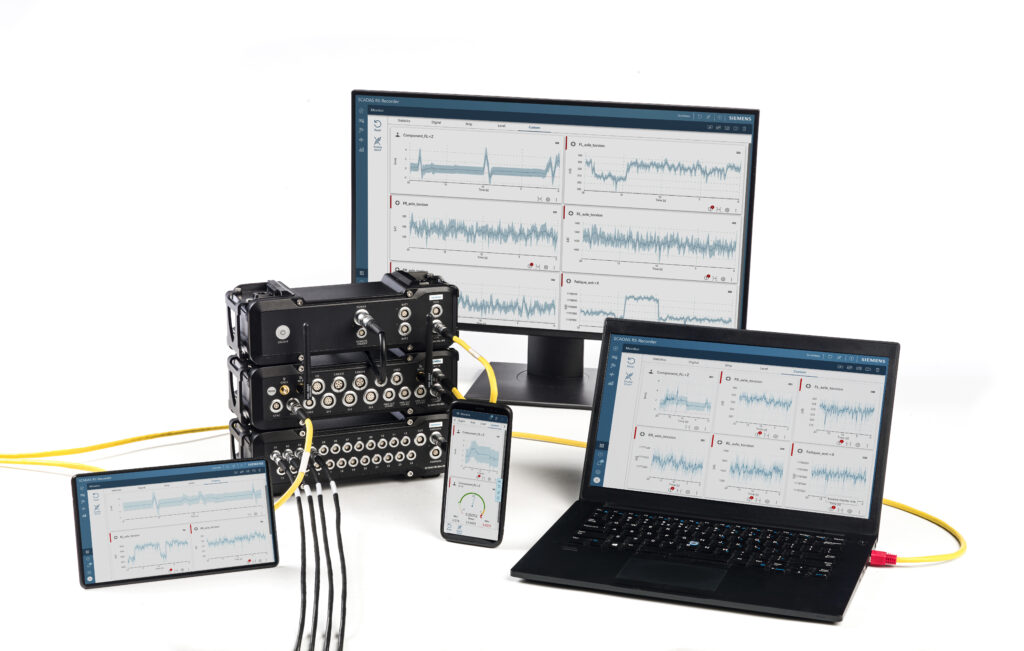

1. Data acquisition system

We used Simcenter SCADAS RS hardware here. There were a couple of important criteria’s for us to chose Simcenter SCADAS RS, such as the fact it is a rugged, compact and scalable setup such that we can set up a system with what exactly we need (not desired to have a bulky system). It also gives us the possibility to cover wide range of different sensors (analog and digital) without any need for an adaptor, converter etc. The brain unit of the system (REC unit) can further be configured for intelligent data capturing using advanced triggers and online calculated channels. And it has an internal solid drive that goes up to 240 GB.

2. Flexible software to connect hardware

To perform different tasks such as channel setup, sensor verification, sensor calibration, online data monitoring etc., we need a software solution which gives access to hardware. Luckily, Simcenter SCADAS RS hardware has an app, Simcenter SCADAS RS Recorder App, running inside the hardware and gives possibility to access through a wired or wireless communication through a web browser. You can use any of your device, either PC, tablet or even mobile phone, to connect hardware independent of the operating system you have on your device. No need for installing a software into your device and multiple people can access the system in parallel.

If you’re close to your test vehicle, you can basically have a physical cable from your PC to hardware. Or, you can connect to the embedded Wi-Fi of Simcenter SCADAS RS if you’re in an accessible range. But here we needed a remote data acquisition solution where we require a mobile network. Check the next item for details.

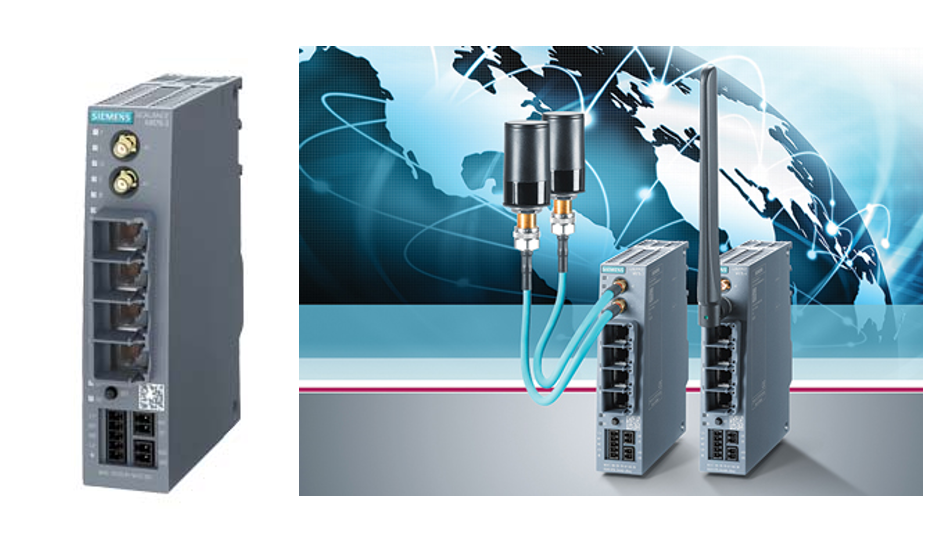

3. Modem and server for remote data access

Here we benefitted from another Siemens solution, SCALANCE M, which enables mobile network. And I should also indicate that Simcenter SCADAS RS hardware is able to work with such modem to stream data remotely to a server – this is quite important for remote data acquisition!

SCALANCE M needs to have a SIM card installed from a public network provider. SCALANCE M modem connected to Simcenter SCADAS RS can be an option here with a limited security, since we can rely on the password credential of Simcenter SCADAS RS and an additional VPN established for SCALANCE M. But we decided to rely on another Siemens solution, SINEMA RC server, which is designed to manage platform for remote networks. SINEMA RC provides encrypted connections with VPN, and it’s possible to control all VPN connections from the server side, which grants a safe and secured environment.

4. Advanced data validation software

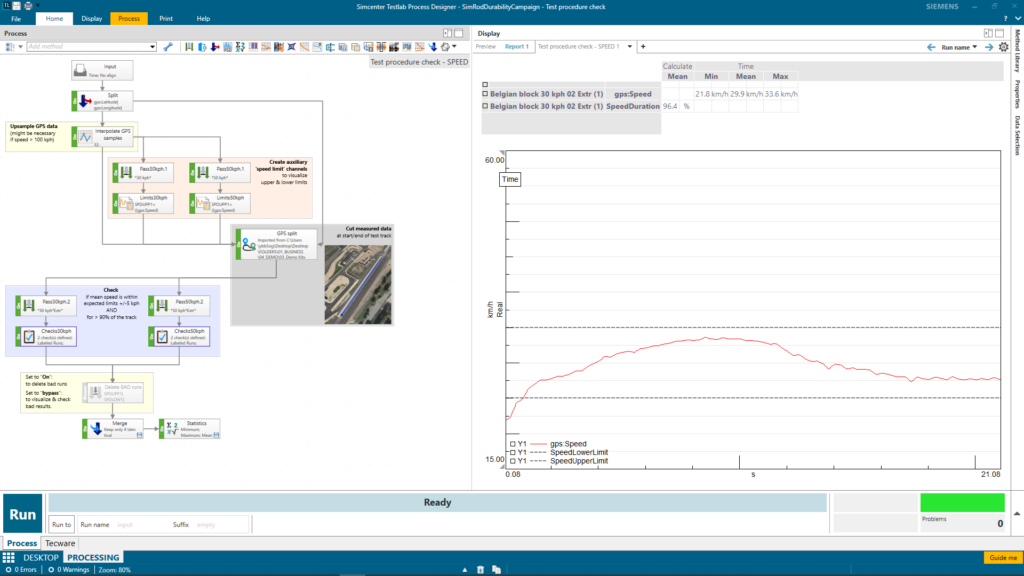

We used Simcenter Testlab software in terms of data consolidation, advanced quality checks and further data classification for detailed load data analysis. You can already get some ideas by checking the raw data. But an advanced analysis solution is anyhow needed if you want to go in details. So, Simcenter Testlab is designed to handle vast amount of data in terms of multi-physics applications (Durability, NVH, Acoustics…) for data acquisition, visualization and processing aspects.

Let’s move on to a real measurement!

I think we are in a great moment to go for a real measurement with remote data acquisition capabilities! We have recorded video images both from the measurement site where Simcenter SCADAS RS hardware is connected to the Siemens SCALANCE modem and from the office where an engineer is connected to the Simcenter SCADAS RS through an established Siemens SINEMA RC server (Siemens SCALANCE modem is already configured in this Siemens SINEMA RC server).

Let’s take a closer look into those combined video images – I tried to embed some banners to make it more comprehensive!

As it is also very obvious from the video, remote hardware access is always possible with the above workflow and its components from anywhere in order to monitor measurement and validate the measured runs. With this way, driver can focus on his driving maneuvers rather than spending effort on data validation. He can still apply some basic statistical checks. But this is a pure engineer task according to me… Luckily, with this way, there is even no need for an engineer on-site. So, the engineer can spend his time on more valuable things, such as post-processing the data before passing it to physical and virtual validation teams.

Automated data validation

Online data monitoring is not always sufficient to validate the measurement before considering it as valid. In this context, as mentioned earlier, we benefitted from Simcenter Testlab after we acquire a large dataset on a proving ground. We acquired multiple runs from a single test track in order to identify ‘the good runs’ afterward. I also requested the driver to acquire with a constant vehicle speed (either 30 km/h or 50 km/h).

At the end of the day, I received 8 runs where the measurements start a few seconds before reaching the track and end a few seconds after the vehicle leave the track. And the vehicle speed for the 30 km/h runs (acquired 4 runs) and 50 km/h runs (acquired another 4 runs) is sometimes a bit higher or lower. So, my post-processing tasks were:

- Cut the whole dataset accurately based on exact track start and end

- Apply a procedure check based on vehicle speed

- I identified two different checks here

- based on mean speed: it should be in between a certain range (km/h)

- based on speed duration: the exact time we spent in between certain speed range (%)

- I identified two different checks here

- Annotate the run based on defined procedures

Let me show you how I did all those with a demo video.

As also indicated by the banners on my demo video, I could automatically cut measured runs based on GPS coordinates of the track. And I eliminated the ‘bad’ runs after applying some procedure checks.

Conclusion

With this blog, I mentioned different components to help you tackle different testing challenges in order to accelerate some time-consuming tasks with remote data acquisition and automated data validation. These are just some certain examples. But we, as Simcenter, would be more than happy to discuss your specific challenges in details in order to come up with the best solution.

Please do not hesitate to contact me directly: safak.has@siemens.com.