Siemens partnering with PRODERA for complete GVT and modal testing solution

Siemens Industry Software recently signed an OEM agreement with PRODERA, a renowned provider of modal testing equipment. PRODERA offers sensors, shakers and suspension systems tailored to aircraft ground vibration testing (GVT) applications. This agreement enables PRODERA to offer a complete solution including Siemens data acquisition, control and analysis systems based on Simcenter SCADAS hardware and Simcenter Testlab software, and the PRODERA equipment.

PRODERA is a well-established supplier of modal testing equipment with a worldwide customer basis. The manufactured range of equipment covers the complete modal analysis domain. It includes electrodynamic shakers, power amplifiers, accelerometers and ground suspension systems. It also provides dedicated equipment for in-flight testing, including telemetry systems and in-flight excitation devices.

Highly-accurate PRODERA modal testing equipment

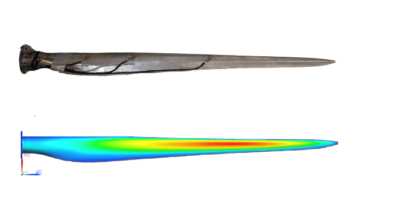

During structural analysis, forces are imposed on the structure and the measured resulting vibrations allow calculation of the modal parameters (resonance frequencies, damping and mode shapes). As it is the basis for all the analysis, modal shakers must be able to provide the requested force for an adapted frequency range, without disturbing the characteristics of the structure under test.

In particular, PRODERA modal electrodynamic shakers are characterized by near-zero suspension stiffness and large stroke. This allows performing highly accurate modal measurements. The current-controlled power amplifiers used to drive the shakers are designed to have a high output impedance, allowing constant force input during frequency sweep without external feedback. A full range of shakers and amplifiers is available to cover force levels from 3 to 5000 Newtons. Suspension Systems are also available for these modal shakers.

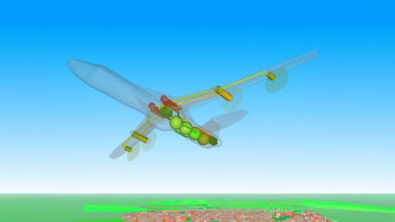

During a ground vibration test, the motion of the structure under test needs to be decoupled from the ground. PRODERA has designed specific suspension systems for structures up to 40 tons with an isolation down to 0.9 Hertz. Such a system allows to improve the accuracy of the measurements. It helps reach the desired level of measurement quality in support of the aircraft certification process.

Combined with Simcenter Testing Solutions

Simcenter testing solutions combine Simcenter SCADAS hardware and Simcenter Testlab software for data acquisition, control, and analysis in the core field of acoustics, vibration, and durability testing. The solution is ideal for large channel count measurements, as required during Ground Vibration Testing. Simcenter SCADAS Hardware allows acquiring data from hundreds of vibration sensors. The modular design of the SCADAS system brings additional flexibility in the test set-up. It guarantees the utmost accuracy in the measurements. Simcenter Testlab Software allows choosing between several excitation methods, such as random, swept, or stepped sine excitation or normal mode testing. State-of-the-art processing capabilities allow performing the modal analysis and extract relevant information from the measured data.

For best accuracy and efficiency in ground vibration testing

Combining the excitation devices, sensors, and suspension systems from PRODERA with the Simcenter data acquisition and processing capabilities from Siemens allows building the most complete and accurate solution on the market for modal testing, especially in the field of aircraft ground vibration testing. Already today, several aerospace companies use PRODERA sensors, shakers, and suspension systems in combination with the GVT hardware and software offered by Siemens. This new partnership will facilitate the deployment of full GVT solutions at more aerospace customers.

Learn more about Ground Vibration Testing and Flutter Analysis

Comments

Comments are closed.