Simcenter 3D Smart Virtual Sensing – Unveiling the Magic

For engineers, measurements hold a wealth of information that can help unlock valuable insights and uncover hidden mysteries. However, there are instances where physical sensors cannot be used to measure certain locations. This is where the Simcenter 3D Smart Virtual Sensing technology excels. It is specifically designed to overcome the limitations of traditional sensing methods. In this blog, we will explore the transformative power of Simcenter 3D Smart Virtual Sensing and understand how it addresses the challenges posed by inaccessible measurement locations.

What is Simcenter 3D Smart Virtual Sensing?

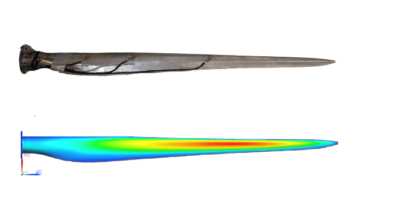

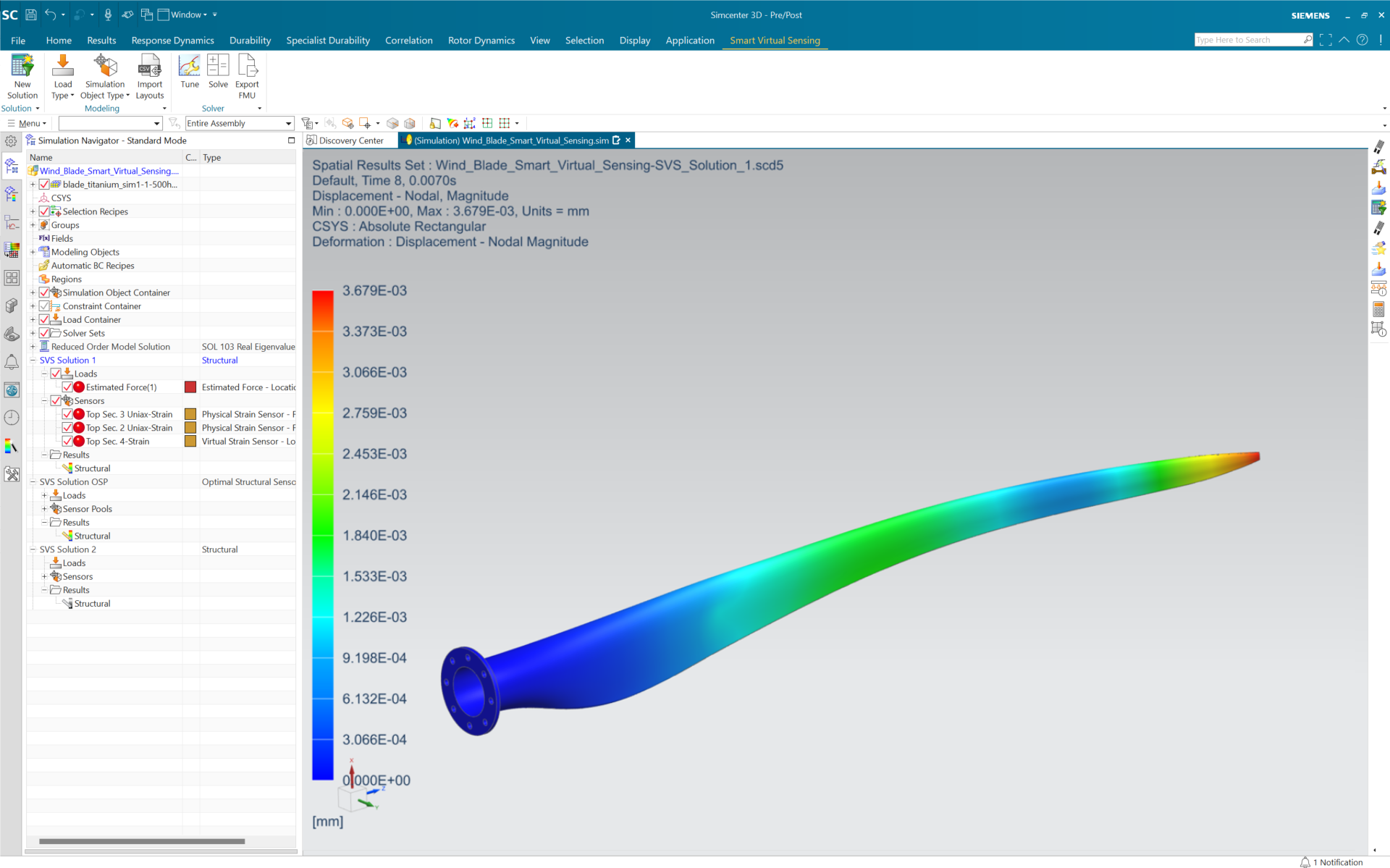

Simcenter 3D Smart Virtual Sensing is an innovative framework that enables you to measure the unmeasurable, reaching into the heart of your designs to bring out hidden truths. By combining the limited physical measurements with a reduce order Finite Element Model (FEM) it creates virtual sensors that provide insights far beyond the traditional methods.

Simcenter 3D Smart Virtual Sensing is the bridge between the virtual world of simulations and the tangible world of testing. It takes the best of both worlds, combining them into a seamless workflow, enabling you to gain insight into your mechanical system offline or in real-time.

It’s like having a crystal ball that can monitor and predict the status of your product. It compensates for both model inaccuracy and measurement errors and provides high-accuracy estimations on the input loads, strains, acceleration, velocity, and displacement of your mechanical system.

Why is it Smart?

Siemens Simcenter 3D takes virtual sensing a step further by introducing “smart” virtual sensing. What sets it apart is the infusion of intelligence into the virtual sensors. Here’s why it’s not just sensing; it’s a revolution.

Data fusion

Smart virtual sensing harmonizes measurement and simulation data through an integrated data fusion method with the Kalman filter, which excels in fusing these diverse sources of information, creating a cohesive and accurate representation of the system’s state by intelligently weighting the contributions of both measurement and simulation so it can compensate for inaccuracies seamlessly.

Adaptive Sensing

With a limited number of real-world sensors providing current data Simcenter Smart Virtual Sensing can dynamically accommodate changes in the system reflecting real-world alterations in virtual sensor estimations automatically.

Real-time estimation

Thanks to the reduced order FE model in the framework, smart virtual sensing can continually refine estimates in real-time, ensuring your virtual sensors stay in sync with the dynamic reality.

Self-learning

The term “smart” implies a level of autonomy and learning. Simcenter 3D Smart Virtual Sensing sensors can learn and update the estimation in every time step, optimizing the estimation over time. This adaptability is a key component in enhancing the accuracy of virtual simulations.

Platform Independence

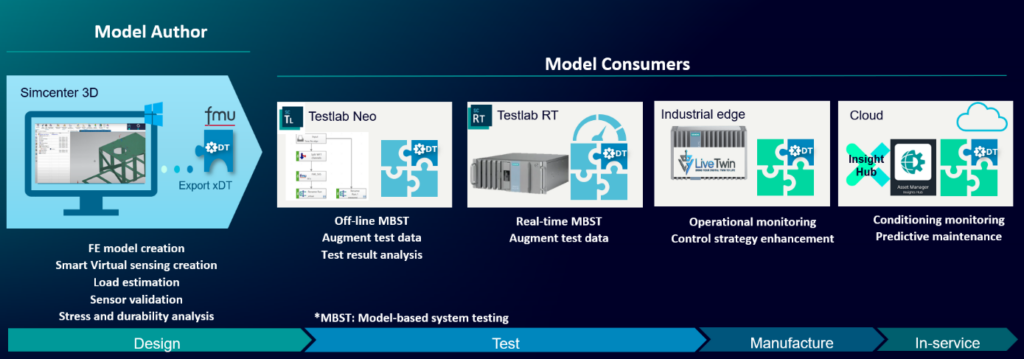

Smart Virtual Sensing not only works within Simcenter 3D for design optimization, but it can also be exported as xDT to work on edge devices, real-time platforms, and the cloud for various applications such as conditioning monitoring, real-time test, and predictive maintenance. It is an intelligent asset that can be used in the whole enterprise across the whole product life cycle.

Why it matters!

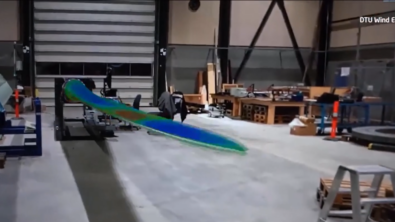

Simcenter 3D Smart Virtual Sensing opens doors to measure the unmeasurable – like strain in inaccessible spots or operational loads that are typically elusive. It’s not just about saving time and money in testing; it’s about pushing the boundaries of what’s possible from design to manufacturing and maintenance.

Testing revolution

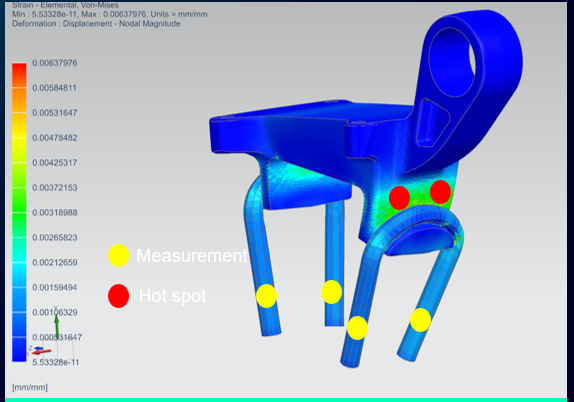

There are several challenges for performing a test campaign: some sensor locations sometimes can not be implemented due to geometry constrains, while adding additional load transducers may change the structure dynamics. Even if all the places are accessible and can be monitored with physical sensors, instrumentation times can be long and hardware costs can be expensive.

With smart virtual sensors, inaccessible spots become measurable. It not only solves the challenge of unplaceable physical sensors but also reduces instrumentation time and hardware costs. The Simcenter 3D Smart Virtual Sensing can connect with Simcenter SCADAS to get the measurement and be deployed within Simcenter Testlab Neo for off-line test results augmentation and within Simcenter Testlab RT for real time Model-based system testing.

Optimizing Designs

In order to validate the design, we need to know how it performs during the working conditions. Simcenter 3D Smart Virtual Sensing measures hot spots remotely, offering full-field stress and strain insights with minimal physical sensors. It can measure operational loads from a few strain gauges. The operational loads in time serials can be further used for durability analysis to find the reason for fatigue. It’s the secret to not just validating designs but pushing them towards optimization.

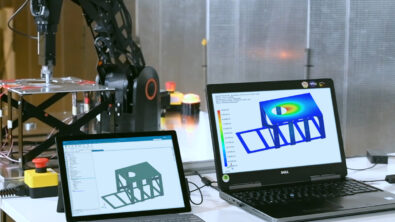

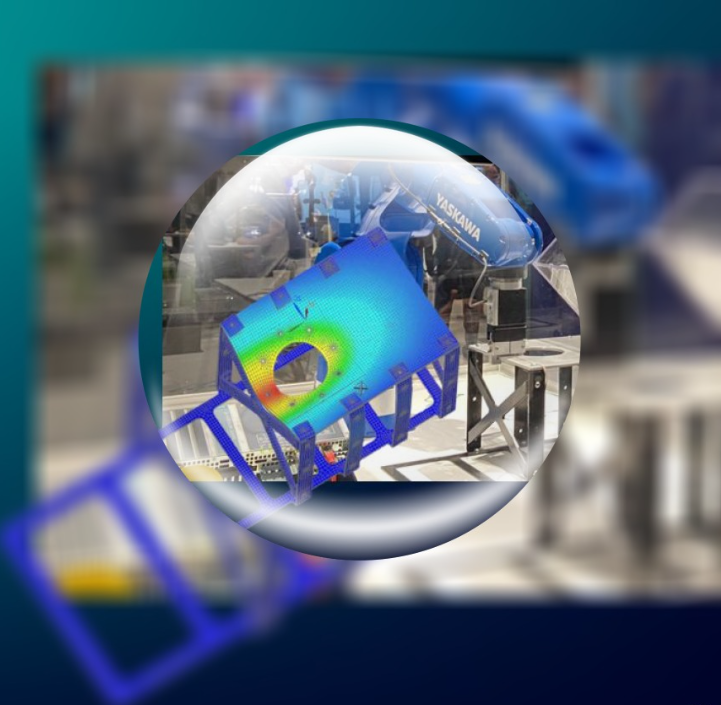

Smart Manufacturing

In the world of manufacturing, Simcenter 3D Smart Virtual Sensing is a game-changer. It reconstructs full strain fields from minimal measurements. It can be deployed on the industrial edge, for easy integration with the PLC control system. Simcenter Smart Virtual Sensing receives physical sensor data from the PLC IO modules. It uses this data for data fusion, the Simcenter Smart virtual Sensing information can then feedback to the PLC to enrich the measurements and improve the control strategies. Furthermore, it enables you to see inside the manufacturing process via a visualization tool. Plus, you can stream the virtual sensing data to the cloud for operation monitoring and asset management for your entire manufacturing process.

Predictive Maintenance

For products in the service phase, Smart Virtual Sensing can be used to ensure efficient maintenance. it is able to do this because it can provide real time insight of a system and self-update to accommodate for changes in the system automatically.

With its ability to enable condition monitoring it can help identify excessive displacement and send warnings. It can help monitor the stress distribution of your machine during the operational phase to verify if the machine is working as expected.

Furthermore, Simcenter Smart Virtual Sensing can combine with real-time durability analysis to indicate the remaining useful lifetime for predictive maintenance.

Simcenter Smart virtual Sensing is the crystal ball that foresees maintenance needs, so you can prevent issues before they disrupt your operations.

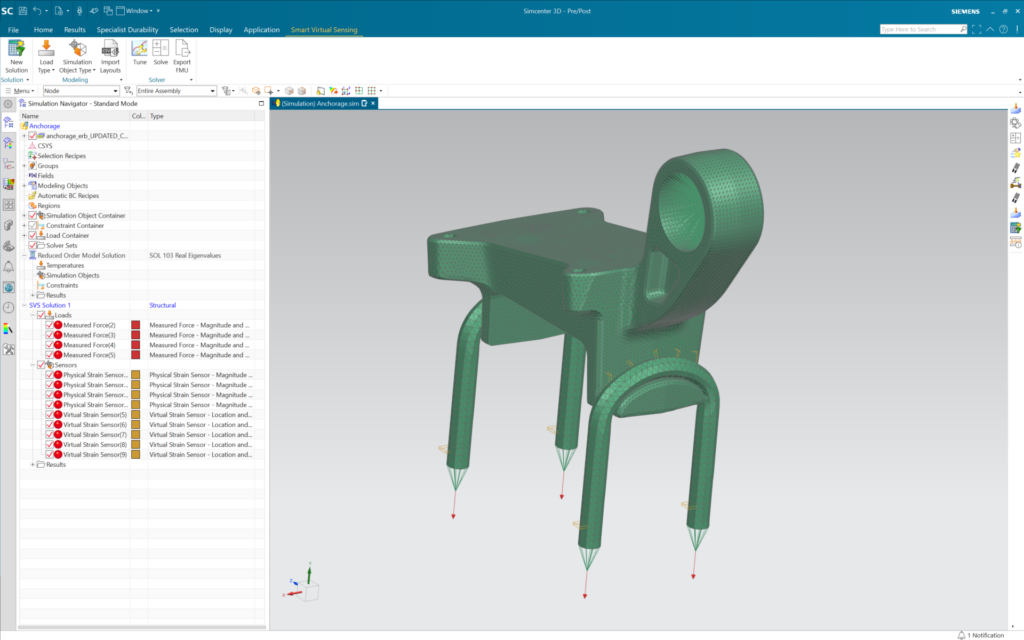

How to implement

Simcenter 3D Smart Virtual Sensing provides an integrated workflow to set up, validate, and deploy virtual sensors across various platforms. Begin the enchantment by defining virtual sensors within the authoring tool- Simcenter 3D, validating estimations, visualizing results, and finally exporting them as executable digital twins (xDTs) for real-time use.

This makes Simcenter 3D Smart Virtual Sensing a versatile tool across various phases of product development.

Conclusion

Simcenter 3D Smart Virtual Sensing offers a robust framework to measure the unmeasurable sensing locations. It enables the creation of physics-based smart virtual sensors xDTs to deploy on different phases of the product lifecycle. The innovative approach enables you to have more efficient tests, faster design optimization, smarter manufacturing, and predictive maintenance. Most importantly, it maximizes the value of the digital twin in the entire enterprise. No longer is this a technology of the future, with Simcenter 3D Smart Virtual Sensing it is the technology of today, existing customers can download the latest version via support center, and all non-customers have to do is follow this link and click download for a free trial.