Simcenter Engineering Services sounds off on electric vehicle performance.

If you ask a child what sound a car makes, I would be willing to bet their answer is “vroom.” At least in the “hear” and now. If current trends hold, that might change. Electric vehicle ownership is rising, changing the soundscape. What onomatopoeia will we use to imitate electric vehicle performance in the future? Psss? Szzzz?

Electric vehicle performance attributes and comfort considerations are quite different—and still evolving. How does testing these attributes factor into all of this? I raised this and other questions with Katleen Michiels, head of the Simcenter Engineering & Consulting testing group at the Center of Excellence in Performance Engineering. Here is part of our conversation:

Can you give us a high-level view of what testing for electric vehicles entails?

It depends a bit on the performance attribute and the type of project. For example, you can focus on road noise, pure motor performance or handling. Depending on your vehicle’s development phase, there are different testing types: benchmarking for target setting, component characterization for modelling and correlation and suitable input loads for models and validation of design variants and modifications.

How is noise different when comparing combustion engines and electric vehicles?

Combustion engines are typically loud at lower frequencies, depending on the type and size of the engine. Let’s say, in general, around 400 to 500 Hertz. And in many driving conditions, that noise masks all kinds of other noises like road noise, air conditioners and pumps, et cetera.

Electric motors are now more silent at lower frequencies, so they no longer mask those noises. But on the other hand, you have a sharper, higher frequency noise.

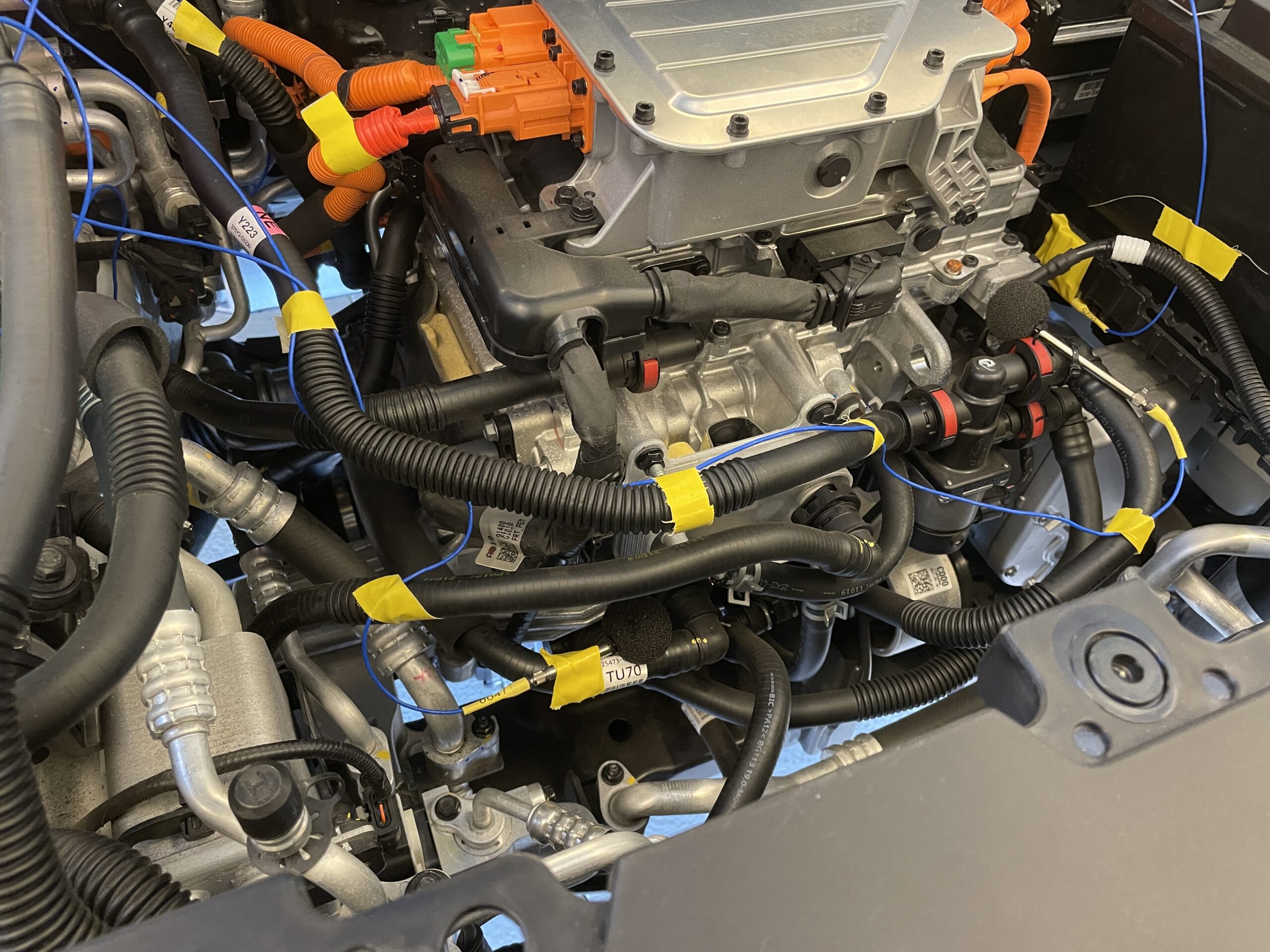

Typically, there are larger tires for electric vehicles. Also, the body, as such, is different because you have this huge and heavy battery underneath. Stiffness is different, and model behaviour is different. You often have motors on the front and rear connected to the subframes and the suspension. Sometimes you even have wheels with in-wheel motors.

So all that affects road noise as well. So it is not just a copy/paste from combustion engines, and you say, “Okay, we use the same technique.” The vehicle’s behaviour is quite different. Besides road noise, you have typical EV noises: regeneration noise, battery charging noise, inverter noise, and noises related to the different driving conditions.

What is misunderstood the most about testing?

People think that test is only in the last stage of a vehicle’s development. And that is only to troubleshoot the latest version of the prototypes for the last-minute improvements. And that’s not at all the case. So testing can take place in the beginning for target setting, getting realistic input loads for early-stage modelling.

We can test on components for correlation and reverse engineering for parameter characterization, all in the function of improving models. Hardware-in-the-loop configurations are also a set of testing that we do. So in all stages of the development cycle, there is a way where you can test. And it is very often in combination or in the function of simulation of models.

So how does the testing then factor into the simulation? How do we plug it back into our digital twins?

There are different ways. You can estimate the loads using test. That is very often a combination of measurement and calculation. And then you apply that to a simulation model. That is (relatively) straightforward. You can correlate and update your simulation model with test-based component representations or tested model parameters. Well-correlated simulation models are then used to further improve the design of components, assemblies or an entire digital twin of the vehicle. The digital twin of the vehicle can be validated with full vehicle testing.

There is also a possibility of hardware in the loop where you have a complete model, your test bench, or a vehicle where a part of it is hardware. Then you can test performance on that piece of hardware, and then it’s in one cycle, a combination of test and simulation.

What also happens sometimes is that you then make a test-based model of a particular component. For example, when you want to focus on a suspension, you know the body part you will keep still — that will remain the same. Then you can make a simple representation based on a test. You couple that with a simulation of your suspension and then simulate whatever modification you want. This is a hybrid model.

In the Testing Electric Vehicle Performance episode of the Engineer Innovation podcast, you can hear our entire conversation, including more great insights from Katleen.