Simcenter Flomaster & FMI: I’d like to connect…

I’d like to connect, how many times have you said it or had it said to you?

Connecting is a term that used frequently in business, be it on LinkedIn or a networking event where we can talk to like-minded individuals and discuss industry trends or just catch up with old friends.

It’s much the same with software, connectivity is a hot topic in the digital engineering world, if there was a LinkedIn for software tools you could easily imagine many scenarios like this. We’ve all heard the saying; two heads are better than one. Well, two software’s are better than one! The challenge is connecting them together in a seamless quick and easy way!

Enter FMI standard. This standard has been gaining popularity over the past few years, and we’ve added support in Simcenter Flomaster to import and export FMUs.

In the FMI standard there are two types of FMU’s: model exchange and co-simulation.

- Model exchange – These FMU’s do not have a solver attached. Instead these rely on the importing tools solver.

- Co-simulation – A third party solver inside the FMU or locally on the machine and Simcenter Flomaster only queries results at a given time step.

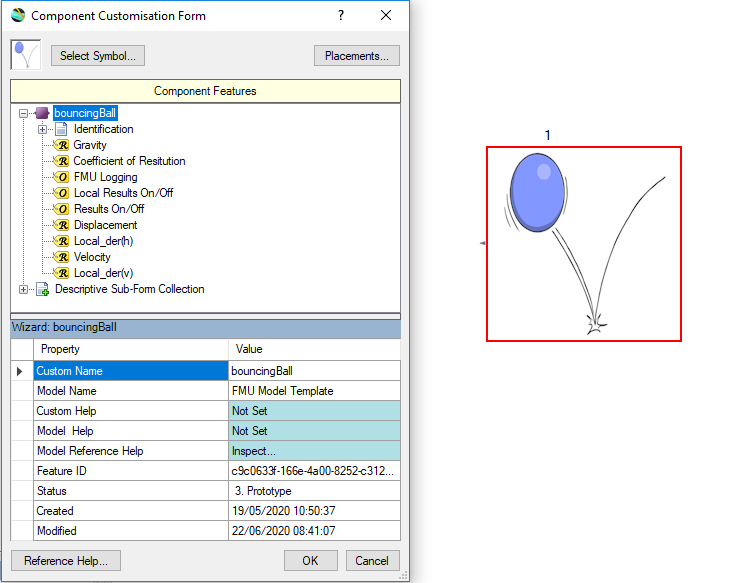

Import of a bouncing ball FMU to Simcenter Flomaster

Let’s look at a simple example of an FMU being imported and solved. A bouncing ball problem, it’s pretty widely known with the scope of the problem ranging from science fair projects to more complex problems like geometric series and ball flight dynamics.

This particular example is simple, a bouncy ball is dropped from 1 metre high with a coefficient of restitution (CoR) of 0.7. What happens to the displacement from the ground as it bounces? This example is a great visual example of how the physics can be modeled and solved.

Once fully imported we can then drag this onto a schematic line any other components and simulate.

A bouncy ball is a simple engineering problem with a set of equations modelling that we can solve. What happens when we increase the complexity and scope of the simulation? What about pumping a fluid and how the design of the pump influences overall performance of the system?

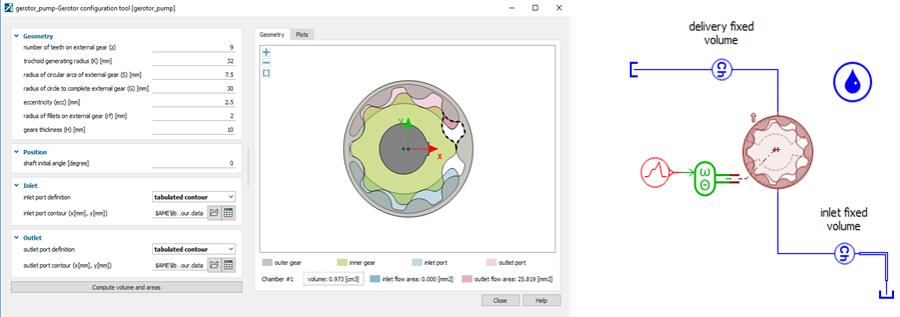

Import from Simcenter Amesim to Simcenter Flomaster of a 3D vane pump.

A more realistic example is looking at how Simcenter Amesim and Simcenter Flomaster can work together on a pumping system and show how the component design in Simcenter Amesim can be supplemented by the overall system design in Simcenter Flomaster. This could be designing a feed system in a bottling plant for food stuffs or even a simple water sprinkler.

Sidebar: We’ll be looking at a water system in this example, but we’ve had a go at modelling more complex fluids in another blog: What would win in a race, Ice Cream or Apple Sauce?

Through the Georotor configuration tool in Simcenter Amesim a pump has been created according to the geometry to gain a better understanding of the individual pump (rather than waiting for the performance data from the manufactures) which can be inputted into Simcenter Flomaster. This allows virtual testing to be frontloaded increasing the overall confidence in the design.

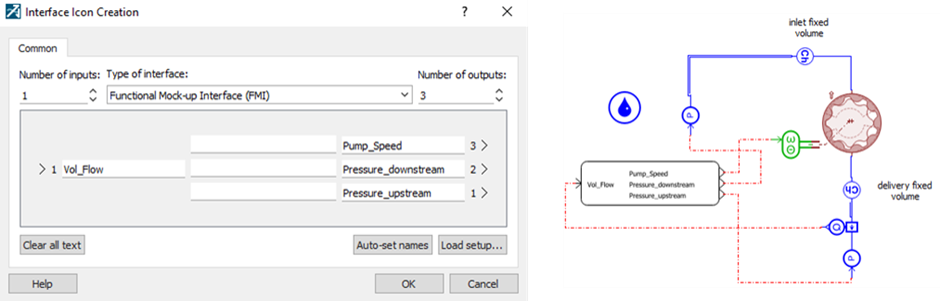

Once generated and set up in a sketch, the model can be imported to Simcenter Flomaster via an FMI interface. To export from Simcenter Amesim, an interface block is needed, this is found under the “Interfaces Create” interface block.

In this case we’ll need one input to the block and three outputs to the block.

The pump speed will be provided by the Simcenter Flomaster control environment and then the upstream and downstream pressures are read in Simcenter Amesim and passed to Simcenter Flomaster. The same is done with a single volumetric flow and then passed to the two flow sources in Simcenter Flomaster.

The imported pump can be dragged onto the schematic and the signals can be connected like any other controller in Simcenter Flomaster.

Now the network can be run like any other network in Simcenter Flomaster. This brings the detailed component design of Simcenter Amesim into the Simcenter Flomaster environment allowing engineers to take advantage of the pump import and the piping capability of Simcenter Flomaster in a single simulation.

If you’d like to know more about Simcenter Flomaster & FMI then take a look at the Tech Tips article.

A longer version of this demo and the simulation set up is explained in more depth in our Tech Tips video on Simcenter Flomaster & FMI Simulations.