Simcenter Flotherm 2020.2: What’s new

This blog reviews enhancements in Simcenter Flotherm 2020.2 electronics cooling simulation software release. The release is focused on extended support to electrothermal circuit simulation and system modeling in boundary condition independent reduced order models (BCI-ROM technology), improved joule heating solver speed, and more … please read on for information and links.

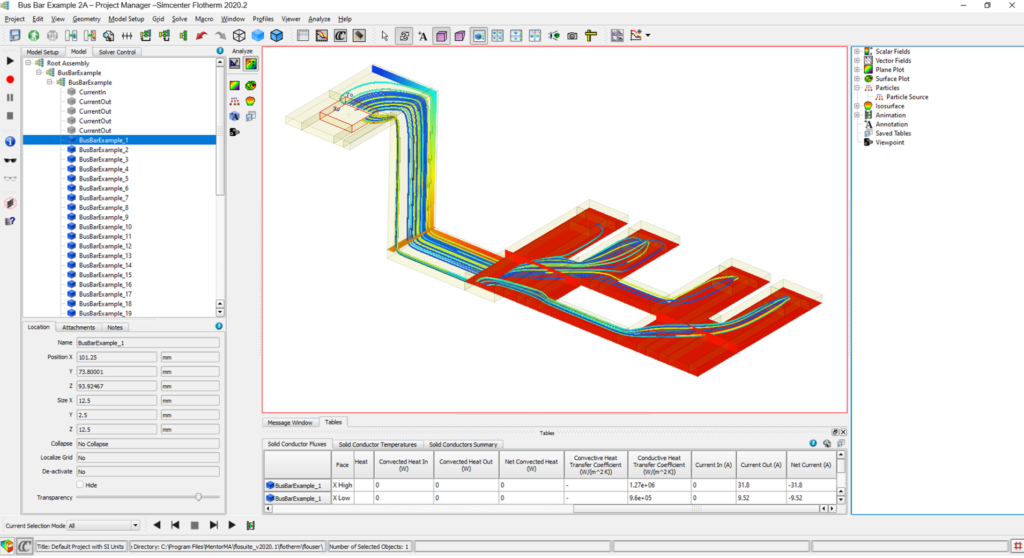

Joule heating simulation – faster

Joule heating solver improvements have been made resulting in significant simulation speed up. Tests indicate a speed up of between 4 -10 times faster!

The impact is obviously model dependent. However, such solve time reduction allows for greater opportunity to evaluate critical joule heating influences in more complex models during development.

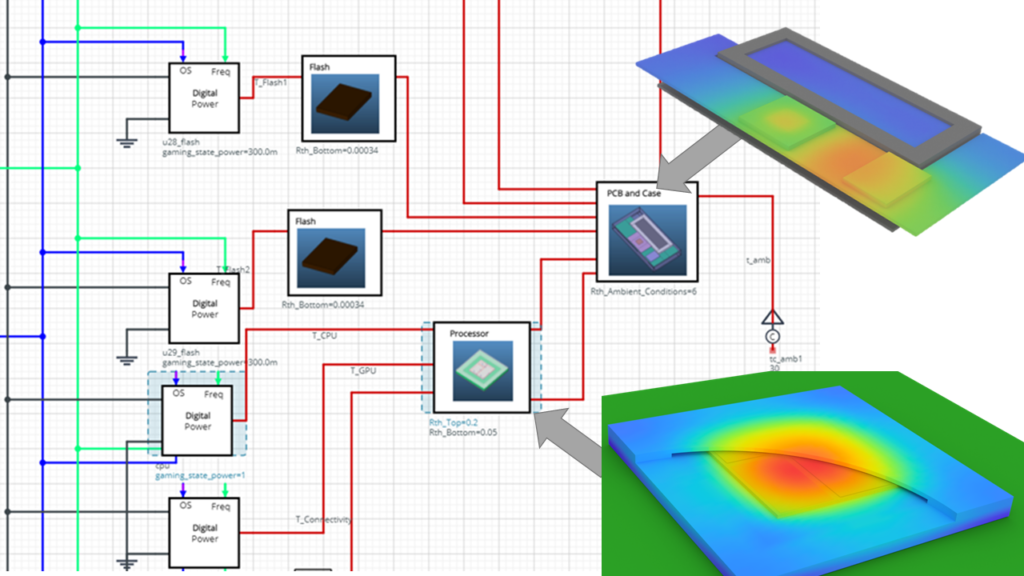

Accurate electrothermal circuit simulation earlier with BCI-ROMs in VHDL-AMS format

Please read Byron Blackmore’s detailed blog “The future of thermal design – earlier electrothermal analysis” for an in-depth focus on this topic and a worked digital electronics example that you can try of a smartphone electrothermal circuit simulation. That example is enabled by several boundary-condition-independent reduced order models (BCI-ROMs) ,in VHDL-AMS format, generated in Simcenter Flotherm.

Building on increasing demand for accuracy in electrothermal circuit simulation environments, and earlier, closer electrical-thermal design workflow, Simcenter Flotherm 2020.2 adds generation of BCI-ROMs in VHDL-AMS format. VHDL-AMS is built on IEEE Standard 1076.1 and is a hardware description language used in multi-domain simulation of analog, digital, and mixed-signal systems. This BCI-ROM format better supports transient modeling of operating modes and power-aware control in a circuit simulation tool. It extends beyond the VHDL-AMS thermal netlist generation capabilities introduced in the prior Simcenter Flotherm 2020.1 release. The thermal model supply chain from semiconductor OEM to electronics integrator is better connected for electrothermal circuit simulation tasks as result.

In short, the “boundary condition independent” aspect of reduced order models is extremely valuable, as this enables BCI-ROMs to be used in any thermal environment, while maintaining accuracy. It makes connected electrical and thermal circuit concurrent modeling achievable. With this release, BCI-ROM technology now supports both BCI-ROM and Thermal Netlist generation in VHDL-AMS and spice format for use with circuit simulation tools such as SystemVision Cloud, Xpedition AMS and many others.

Further reduced order modeling enhancements, including for 1D system simulation

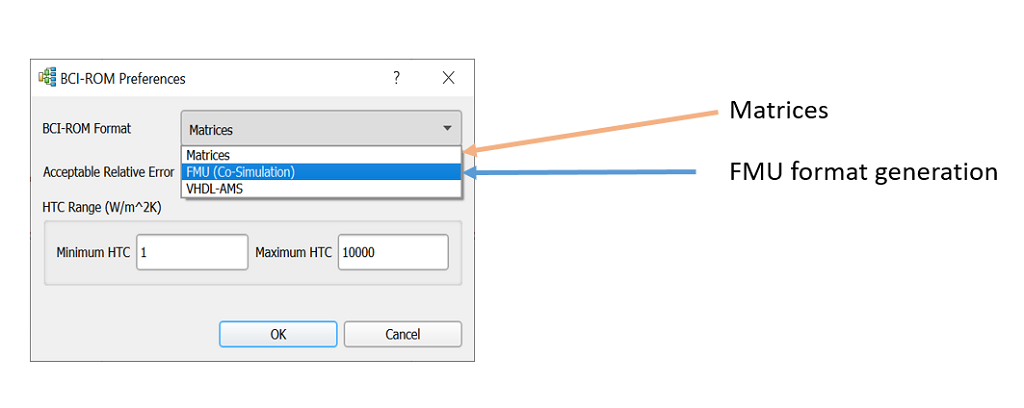

Simcenter Flotherm BCI-ROM technology creates fast solving, accurate reduced order models from a 3D conduction thermal model and can be utilized in several different formats. Formats generated can run in 3rd party numerical computational tools to solve BCI-ROM matrices, in circuit simulation modeling tools (see above) and also in 1D system modeling tools (FMU format). Now it is possible also to solve BCI-ROM matrices for fast transient thermal studies in a Simcenter Flotherm standalone utility.

New Command line utility to solve BCI ROM Matrices

Simcenter Flotherm 2020.2 introduces a command line utility “BCI-ROM Matrices Standalone Solver for Simcenter Flotherm” which complements existing methods utilizing solver harnesses in 3rd party software tools. The standalone utility installs as an executable with the software. To generate BCI-ROM matrices, you simply select export option “Matrices” in the preferences window.

BCI-ROM Export option to create the Functional Mock Up (FMU) for System Simulation

BCI-ROM generation in FMU format for system simulation tools such as Simcenter Flomaster , Simcenter Amesim and others was introduced at Simcenter Flotherm 2020.1. Now in version 2020.2, generation is much easier within the interface, by selecting FMU directly as an export option rather than via a command line utility.

BCI-ROM FMU Video example: As a recap of one example of using Simcenter Flotherm generated BCI-ROMs in FMU format, I refer you to this video on a liquid cooling simulation performed in Simcenter Flomaster – View on YouTube or review the related blog.

Other Simcenter Flotherm 2020.2 enhancements

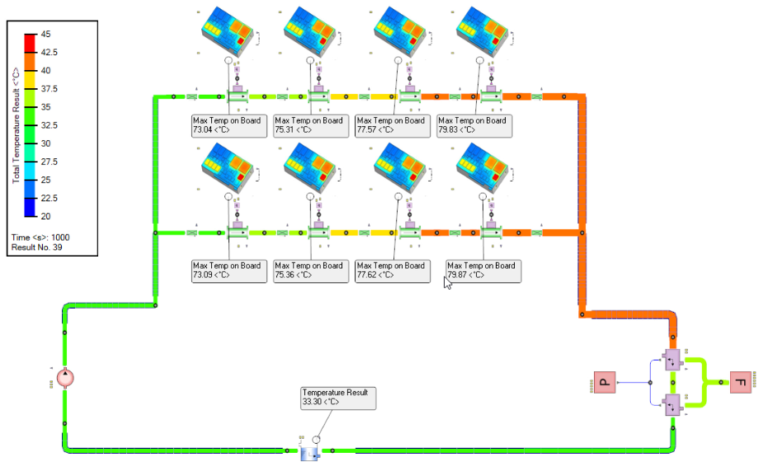

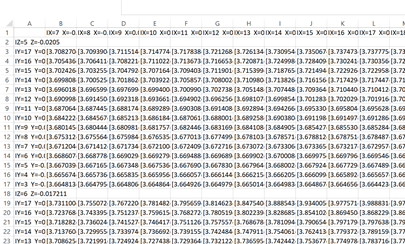

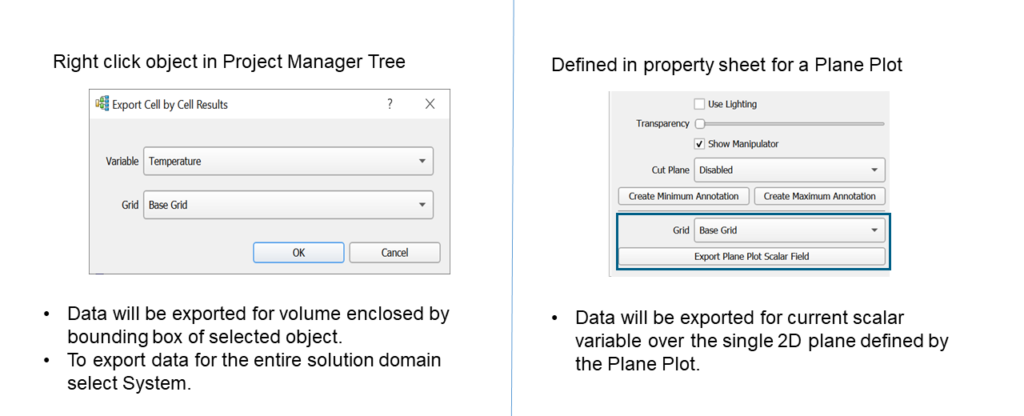

Export Cell by Cell Results easily

You can now export cell by cell results easily in 2 ways that will generate a csv file when in analyze mode.

Important for clients: Select Beta features are available to preview in this software release and provide feedback on. Please see release highlights document in Siemens Support Center for details of these and how to accept terms and activate easily, directly in the software in simple steps.

Additional topic: CFD and FEA analysis workflows for thermo-mechanical analysis

If you are interested in electronics thermal and thermo-mechanical stress analysis workflows, please see this recent presentation by several colleagues available as an on-demand video:

Enhancing electronics thermo-mechanical analysis workflow

It features a variety of example processes going from electronics cooling CFD studies in different tools to FEA analysis. One particular IC package example shows an automated workflow driving a full Simcenter Flotherm thermal CFD simulation, which generates temperature data to execute execute an FEA thermo-mechanical stress analysis in Simcenter 3D multi-physics software. The study goes further with design exploration, enabled by Simcenter HEEDS, to identify remedial package design improvement opportunities.