So what is FOWLP and its applications?

Well, simply put, it is a relatively new high-density advanced packaging technology: Fan-Out Wafer-Level Packaging. Smartphones and wireless multimedia are the first large commercial segment to use FOWLP designs, as seen in the newer iPhones from Apple. Most recently, the growth in vehicle electrification and autonomy is also driving increasing application of FOWLP solutions.

Unlike most WLP packaging flows, where the integrated circuit on the wafer is encapsulated and then diced, like conventional packaging, the FOWLP process dices the wafer first. The clever bit is in the way the die is overmolded and the redistribution layer (RDL) created, to provide fan out for the solder balls.

FOWLP offers multiple advantages over conventional packaging technologies:

- Higher performance

- Shorter interconnect paths lead to fewer parasitics and less delay.

- Shorter paths to heatsinks reduce concerns about *thermal impacts and resistance.

- Lower power consumption.

- Improved form factor

- Thinner and lighter than traditional 2.5D and 3D packaging

- Option to place even more components vertically, reducing footprint.

*Thermally, one of the main benefits of having a package that is larger than the die is that it can help spread the heat before it is removed by a heatsink. FOWLP has the unfortunate effect of kicking that particular can down the road, placing greater demands on the thermal performance of the board, heatsink, and thermal interface material between heatsink and package.

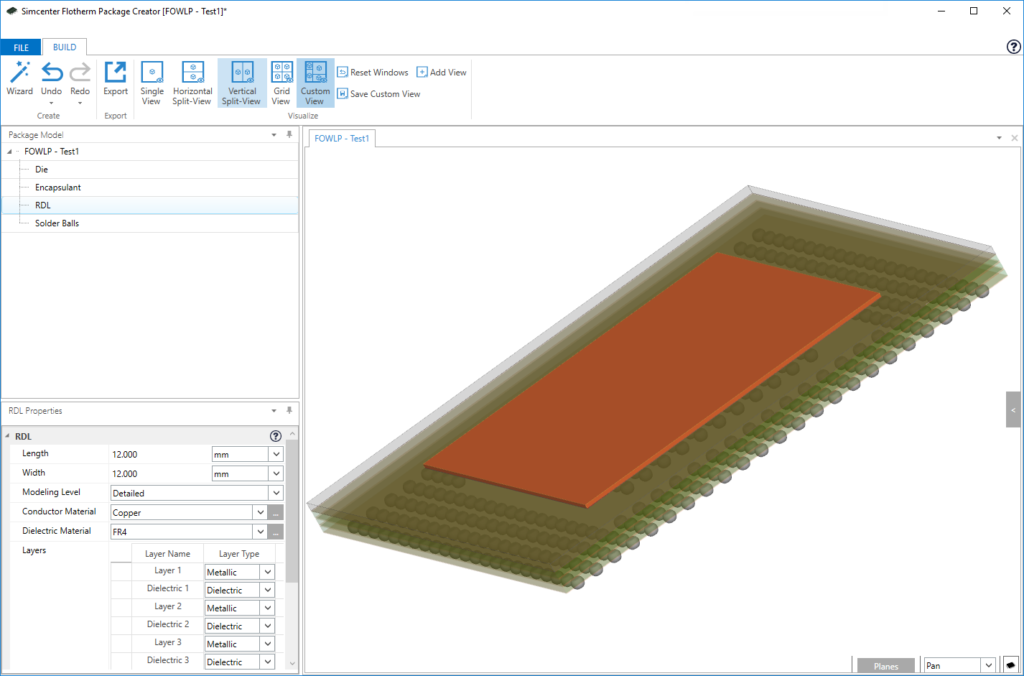

The good news is that with the new Package Creator module, delivered with the Simcenter Flotherm XT 2019.3 release, we are offering modelling support for FOWLP devices. The image below shows the set-up for the RDL for a typical FOWLP design.

Try Simcenter Flotherm XT for yourself with a free 30-day cloud evaluation. Become proficient at driving Simcenter Flotherm XT Ultra by working through case studies. Use Simcenter Flotherm XT’s Smartparts and Parts Library to create accurate thermal models faster; capture Electronic data using FloEDA Bridge; and visualize the results on the original CAD geometry.