STAR-CCM+ drives InDesA’s digital twin development through 1D and 3D co-simulation

Gone are your father’s engines, the ones that polluted the air and burned a tank of gas by the time he drove the car home from work. In today’s climate, bigger isn’t necessarily better, and concerns for the environment are being taken seriously. One thing that has remained constant is consumers’ desire to get more for less, especially when it comes to fuel consumption. That’s not to say that the size of a vehicle’s engine isn’t important, but something has to give if you’re going to meet governmental emissions regulations and minimize gas consumption while still maintaining the same level of performance.

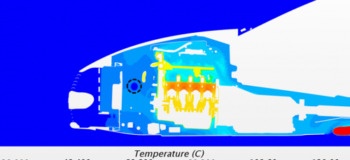

Trying to navigate this modern set of concerns, engineers are forced to come up with new ways to design more efficient engines. Not exactly an easy task, and as such in order to achieve these design goals the trend is pointing toward engine downsizing and lower aerodynamic drag to reduce energy use of the vehicle while adding power electronics for improved safety and comfort. To meet these goals, vehicle designers are looking at smaller, more streamlined grill openings, increased compression ratios, and turbocharged engines. All of these changes put a larger thermal constraint on automotive design. As discovered by InDesA GmbH, a German consulting and engineering services firm that specializes in the design, simulation, and analysis of vehicle thermal and energy management systems, the answer may just lie in the concept of the “digital twin.”

InDesA has developed an innovative approach that combines 1D simulation with STAR-CCM+® software, Siemens PLM software’s flagship 3D computational fluid dynamics (CFD) code, for accurate fluid-thermal systems-level simulation.

InDesA uses STAR-CCM+ for fluid-thermal analysis to provide a detailed knowledge of a component’s design, and 1D simulation tools for rapid engine and vehicle simulation. InDesA is able to employ a diverse range of simulation tools – along with their extensive experience – to successfully solve complex engineering problems.

In the Pandora GT, for example, InDesA uses a generic digital twin to develop advanced simulation methodologies on a consistent geometry and for the demonstration of thermal management technologies and concepts. The GT-Pandora vehicle includes detail such as external bodywork, powertrain, cooling and climate control circuit and exhaust system. As turbocharging is a widely-used technology to increase power when downsizing an engine in order to reduce emission, the design of the charge air cooler is critical to ensure the air temperature after compression enters the engine at a level such that engine knock is prevented. The linking of tools allow for the simulation of real-world conditions to evaluate the performance of the cooling system through extreme operating conditions.

In our recent webinar held on September 14, 2017, InDesA shows a concept car designed fully within a digital test environment. The vehicle looks at cooling circuit, powertrain and exhaust systems to explore new concepts and hardware configuration to reduce harmful emissions and fuel consumption during a vehicle drive cycle.