Surfboard CFD – Riding the Digital Wave

The flip-flop engineering symposium

Monday, December 9, 2019, 7 pm. Sunset Beach Elementary School Cafeteria, Oahu’s North Shore, Hawaii. Two laptops and a projector, the child-sized chairs arranged in auditorium style seating, and a paper Christmas tree, presumably made by the children that would normally occupy the tiny chairs, is pinned to the wall. The venue offers no obvious clues as to what the next two hours will bring. And while the room is packed with people ranging from industry leaders to high-performing athletes their attire of shorts and t-shirts make it impossible to grasp the objective of this meeting. And even when Marc in het Panhius, Luca Oggiano, David Shormann, and Eric Arakawa walk on stage one after the other, with their flip-flops still shedding sand from the beach across the street, I still had no idea that I was about to witness an outstanding engineering achievement and an amazing lesson on Surfboard CFD.

Across the street from the 2019 Billabong Pipemasters contest, the Surf Engineering Association (SEA), hosted the first ever Annual Surf Science Symposium. The presentation on additive manufacturing, big data in the cloud, biomimicry, computer aided structural analysis, and computational fluid dynamics that followed was a sharp contradiction to the sunny beach and laid-back flip-flop and boardshort uniformed panel. The methodologies presented by the four panelists read like a cookbook of disruptive engineering technologies. Technologies applied for only one goal: design superior surfboards.

The soul and the surf industry

But why, you might ask, is all this technology really required? Surfing has existed for hundreds of years. For those that get close to the “soul of surfing”, riding the wave is an art, just like shaping a surfboard. Hardcore surfers base their entire lifestyle around the sport, and the spirit of surfing has become a cliché in a dimension yet unseen for any other sport.

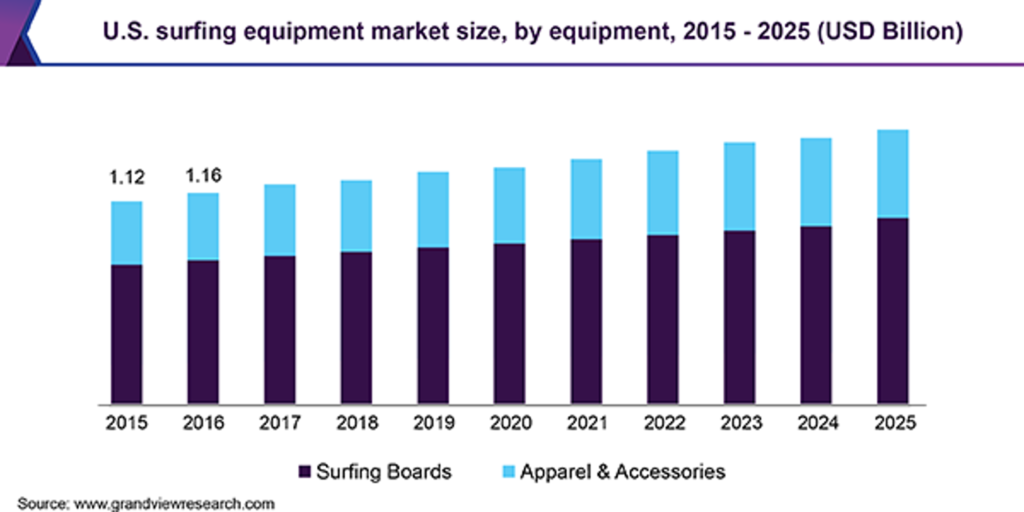

Surfing has become a huge industry, with established brands and continuous technology improvements. The sport is due to become an Olympic sport, but like many things this past year, COVID-19 has delayed this. All over the world artificial wave pools are being built to make the sport accessible to the masses. Recent figures indicate that the surfing industry is worth several billion USD and one of the fastest-growing action sports industries in the world. In short, the sport is being taken seriously and has outgrown its niche market.

There is a big “However!” Marc in het Panhius, researcher, engineer and surfer explains:

Most companies in the surfing industry use the emotion of a surfer to get the consumer to identify with their products and brand. This combined with the ability to use high profile surfers from all around the world is what drives marketing campaigns and business for the bigger companies. However, has anyone ever thought about taking a scientific engineering approach to designing and testing a range of different surfboards and or fins?

Marc in het Panhius, researcher, engineer and surfer

The answer even in 2020 is indeed quite surprising: “Not really”

The systematic disruption of the surfboard industry

Based on this assumption Marc in het Panhius, Luca Oggiano, David Shormann, and Jimmy Freese formed the Surfboard Engineering Association (SEA). Their ambitious goal is simple: To disrupt the surfboard industry with a systematic scientific engineering approach. But not in a conventional manner: “It’s all about mixing two worlds focusing on the same problem but from two very different perspectives.” Luca explains.

And like his colleagues, Luca a sports aerodynamicist; CFD expert; associate professor at Norwegian University of Science and Technology, and a passionate surfer, takes the mission very seriously. Computational Fluid Dynamics Simulation (CFD) of Surfboards has become one of his research focus areas and is now even an intrinsic part of his offerings at NablaFlow, Luca’s startup, that aims to bring to the average user a wide range of fluid flow analysis, such as wind engineering, aerodynamics and multiphase flow.

We are trying to blend the traditional soul shaping approach with a rigid engineering approach to come up with superior surfboard designs.

Luca Oggiano, Surfer and CFD engineer

What makes a superior surfboard?

For an engineer that is not into surfing the first question to ask is probably this “What exactly is it that makes a surfboard superior over another?”

The first thing to understand is what defines an outstanding ride for a surfer. Clearly speed, agility, control and therefore safety, are on the list, but there are trade-offs between those attributes. As well as this, finding the right balance between these attributes is a very individual and personal thing, that depends on a surfer’s style, skillset, preferences and where they surf taking wave energy, size and shape into consideration.

Even if the target specifications are defined, the engineer will ask what are the quantifiable, engineering metrics of the board that then translate into that outstanding ride experience for a surfer. And finally, even if you quantified those metrics that classify a board, how do you design a board to meet those?

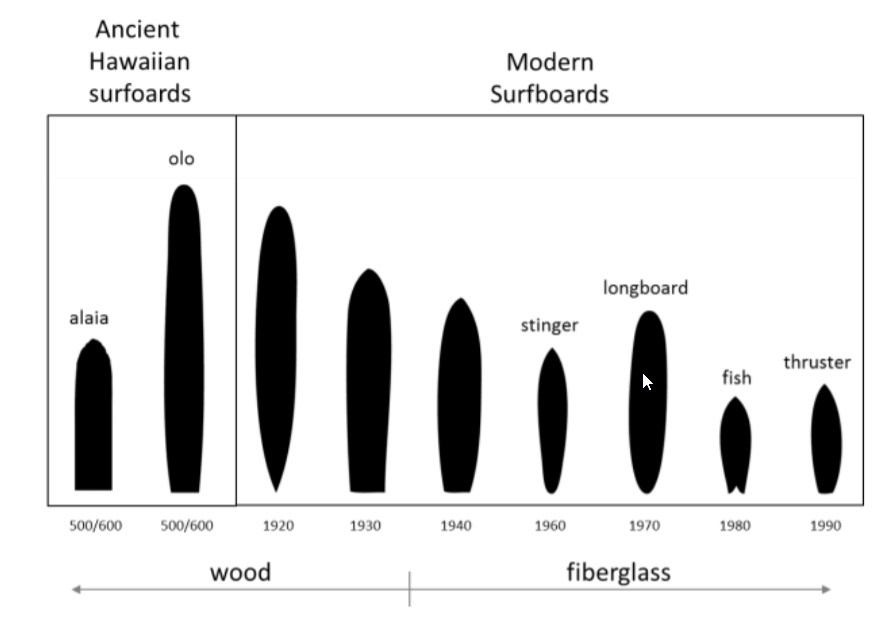

Long gone are the days when surfboards could solely be specified by their shape and length. And while over the years the breadth of surfboards styles has exploded, there is barely any systematic rigid engineering approach.

Professional surfers in the future will no longer pick their boards based on their feelings, but on the conditions and results that are available. Therefore, as engineers our major goal is no longer simply to define a board in terms of its shape or its geometrical quantities. Instead what we would like to do is define a board in terms of its performance attributes. To meet customer expectations, surfboards in the 21st century must be engineered in terms of targeted performance attributes.

Luca Oggiano

As a consequence, surfboards designed for modern surfers come with an explosion of complexity in their development. This will require a disruptive yet systematic engineering approach, an approach that already adopted in many other sports.

Riding the digital wave with Surfboard CFD

The good news is that today, engineers and surfboard designers already have the relevant tools to make this shift happen. With today’s technology a comprehensive digital twin of a surfboard is within reach. Boards can be designed and their performance tested using computer aided design (CAE) tools before any real shaping is takes place. The boards can then be optimized based on the insights their digital twin delivers and even the wildest shapes could be realized thanks to advanced manufacturing processes such as additive manufacturing. Finally, in-situ real world data acquisition can be used to feedback experiences from the field into the design process and result in a continuous improvement loop.

Surfing is a watersport, so it is no surprise that among the tools that are of paramount importance to deliver insight into a surfboard’s performance is CFD. “To me Surfboard CFD is a design tool that should become an intrinsic part of the design process.” Luca says. “A knowledge gaining tool, indicating what is really happening, what are the physics that are making a good or a bad shape, fin, board.”

Now the question remains, what are the engineering attributes gained from Surfboard CFD that translate into speed, agility, control (safety) and stability? In cycling, applying CFD is a little easier because all you want to do is reduce drag. In surfing using CFD will be about defining multiple properties of a board: “In the first place, this can be the forces and moments, lift and drag, ultimately also lift and drag distributions.” Luca explains.

The state of CFD in the surfboard industry

Despite these challenges and opportunities, the state of CFD in the surfboard industry is lagging: “At best you will find a limited use of CFD looking at a fixed board or a single fin under steady state flow conditions.” Luca explains. And while this type of simulation already delivers the initial guidance on a design’s performance, it will only have limited value to achieve the complex goal of virtually designing customized attributed boards. Therefore, an important first step towards more relevant predictions is further increasing realism in the CFD simulations.

Considering transient maneuvers on the surface of a flat ocean with a moving board that undertakes a prescribed motion is a significant first step. This includes events such as turns or stalling. “Using these types of simulations in conjunction with real surfing experiences you already can get a valuable engineering understanding of what a surfer feels during these maneuvers.” says David “and compare different board and fin designs and gain detailed insights, how differentiators in the design are affecting core performance indicators” Luca adds.

The humpback whale project: Assessing the value of Surfboard CFD

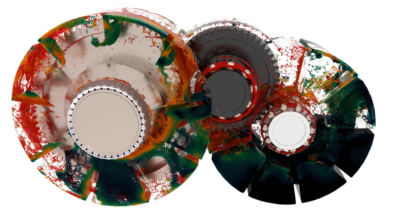

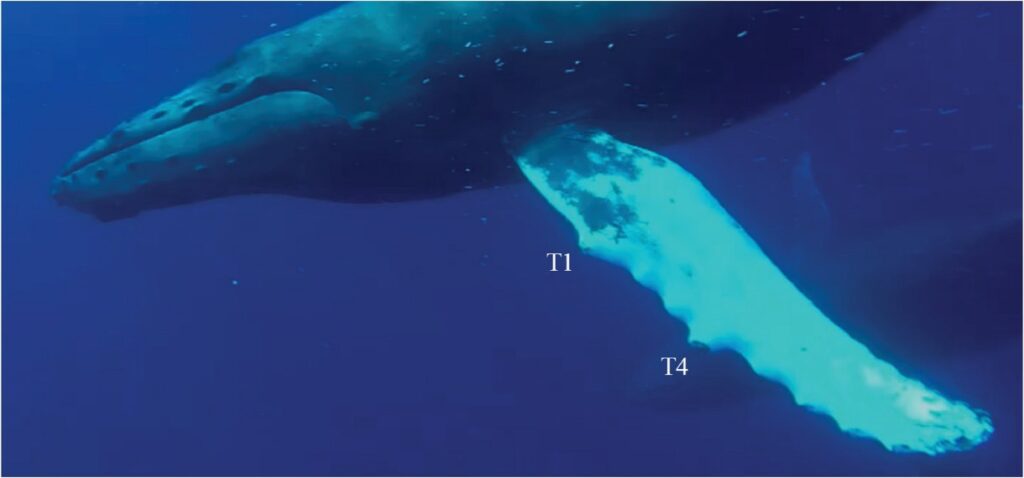

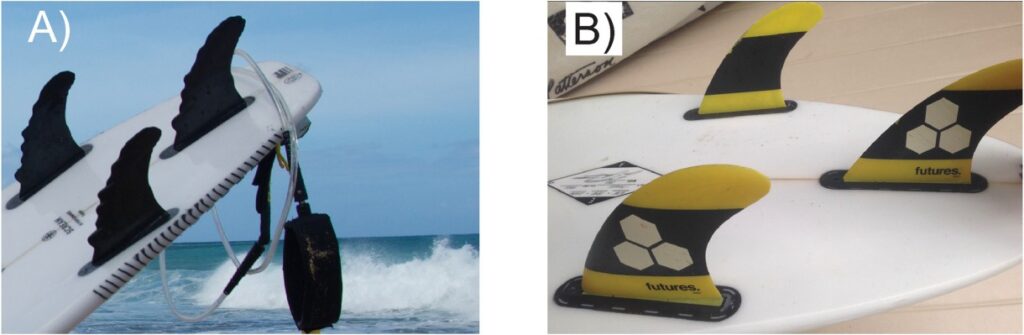

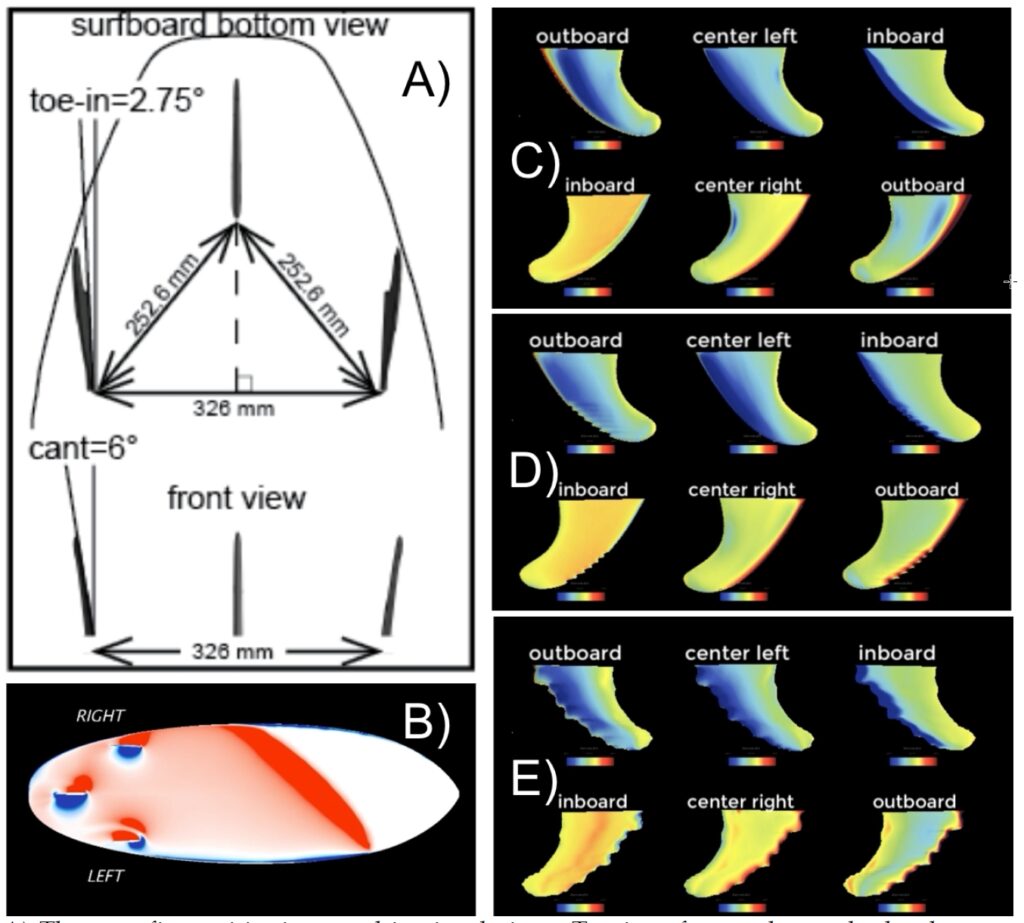

To assess the value of CFD for surfboard engineering Luca, David and Marc started a joint project exploring non-standard fin designs to provide improved performance and safety. The goal was to compare standard surfboard fins with those inspired by the fins of humpback whales, resulting from a classical biomimicry approach.

Why humpback whales you might ask? It is well known in maritime biology and the marine industry, that unique flipper designs give the humpback whale extreme maneuverability. Leading edge bumps, also known as tubercles, improve stability of the whale’s movement through the water by two major mechanisms: First, they foster a delayed stall, meaning the whale can increase the fin’s angle of attack further before flow detachment separation occurs, leading to a loss of control. Second, even under stalling conditions the drop of lift over drag does not happen suddenly, as the angle of attack increases but more gradually. Finally, humpback whale fins are known to be more efficient, meaning less energy is required for the whale to move at a given speed.

All that said, the hypothesis for surfboards was considered. Humpback type fins featuring tubercles, should provide enhanced control during a cutback, when a surfer rapidly changes direction.

Gathering big data in the ocean

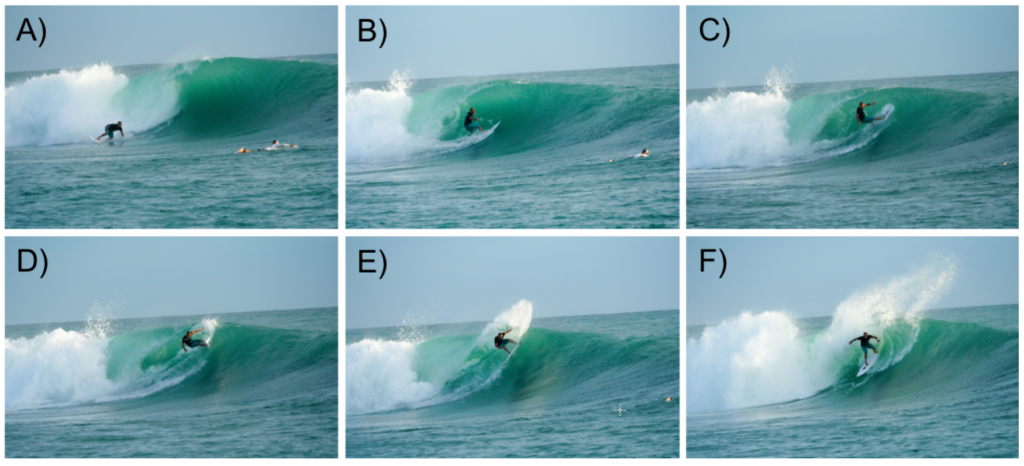

To really assess the value of CFD, the engineers at NablaFlow analyzed this hypothesis with simulation and compared them to the experiences gathered in the field or – to be precise – the ocean. In a first step, GPS sensors with 9-axis motion sensors were used to collect data on nearly 2,000 surfed waves. Data was collected from four surfers of differing skill levels, ranging from intermediate, advanced through to top-ranked professional. On their shortboards with a three-fin configuration some surfers used one of three different fin types: a standard commercial fin; grooved fins; and the 3D-printed, humpback whale-inspired fin with typical tubercles.

The first, unsurprising, experimental result the engineers observed was a positive correlation between surfer skill level and the roll, pitch and yaw rates during a cutback. That is, a more skilled surfer will be able to push a more aggressive, faster turn. Those averaged turn rates for each respective surfer level and fin type from the field research then went into simulation to define the prescribed motion of the respective board and fins.

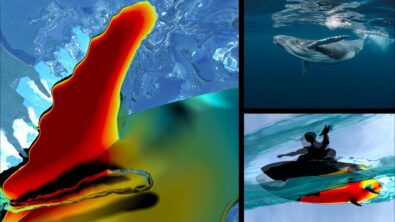

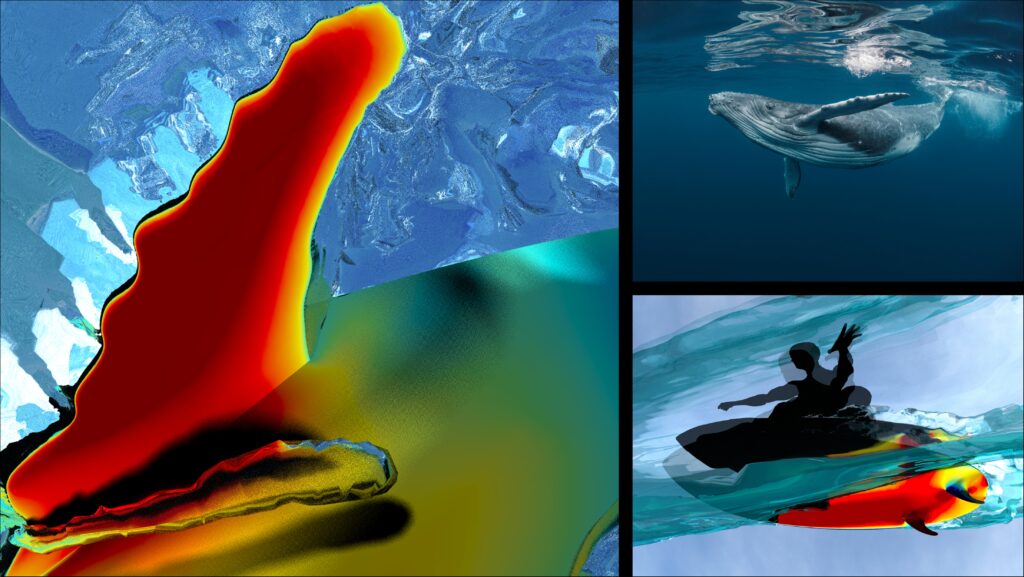

Flatwater Surfboard CFD

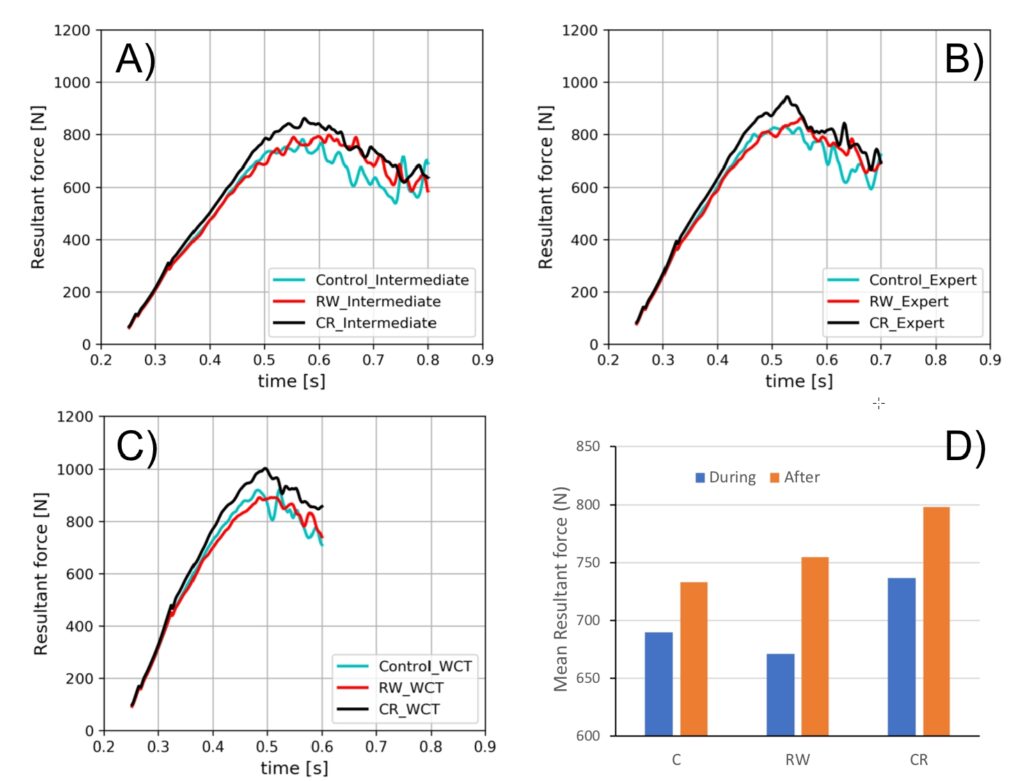

Transient CFD simulations using Simcenter STAR-CCM+ on a flatwater surface were conducted and the sustained resultant forces relative to the rider direction were monitored over time during the respective turns. In a nutshell these forces represent how much the surfer must push to realize a given turn rate.

And while the flatwater surface clearly still is an approximation compared to the real ride on a breaking wave, it offers relevant engineering insights, that are impossible to gain from steady state simulations and rather expensive to obtain experimentally on a regular basis.

Validation of the Surfboard CFD predictions

The CFD simulations predicted lower forces for the whale-inspired fins (RW) during the turn suggesting a less-skilled surfer could generate faster and more powerful turns using those fins. Likewise, in the field statistically significant cutback performance improvements were seen when surfers used the whale-inspired fin. In line with field results, the CFD predicted that an expert surfer performed closer to a world class surfer when using the whale inspired fins, but not when using control fins. The lower resultant forces acting on whale-inspired fin designs during cutbacks suggests that fins with tubercles are more maneuverable compared to the fin designs with grooves and a smooth surface. In surfing parlance this would translate to improved ability to “pivot” more easily. In contrast, the study also reveals that fins with a grooved surface always exhibited the highest mean resultant forces at the most negative angle. In other words, the greatest overall force in opposition to the rider, usually described by surfers as the “hold” to the wave.

The magic of Surfboard CFD – all data at all times in all places

It’s not only the absolute values of forces that reveal insights on the surfboard performance. Looking at the temporal fluctuations of forces reveals clear indications of the stability of the board during the maneuver. A steadier force for the surfer to respond to during the cutback and recovery means a more stable, hence easier to control, board. As the fluctuations in force especially towards the end of the turn reveal, the CFD simulations suggest that the whale-inspired fins should give the best control – in line with the measurements. Further beneficial to a steadier ride is the tubercles’ tendency to a delayed more gradual stall, both observed in CFD and experiment.

While the whale-inspired fin offers more maneuverability and stability, the study also showed that conventionally grooved fins could be more suitable for speed generation or “drive” in surfing parlance. This could suggest that they perform best in wave conditions where speed generation and increased hold on the wave are required.

Surfers could therefore enhance their surfing experience depending on the type of surfing they want to achieve. Fins with tubercles would lead to more maneuverability, whereas fins with grooves would result in increased ability to generate speed and hold compared to fin designs with smooth surfaces.

The deep dive – unrivaled insights from Surfboard CFD

The insights coming from CFD do not stop at those integral numbers. The big insights come from the simulation where all relevant data is always accessible at all locations of the board at all times of a maneuver. That said, the engineer and surfboard designer will not only be able to digitally predict a surfboard’s performance, but they will be able to truly understand and correlate integrated performance numbers with local flow conditions and ultimately take targeted corrective actions for performance improvements. In the whale-fin project a detailed analysis of the CFD results from Simcenter STAR-CCM+ showed the importance of the respective fin-fin and fin-board interaction of the three-fin design depending on their particular shape.

The increasing variability of control forces in all designs towards the end of each turn is resulting from turbulence from both the board and fins.

Towards the end of a turn, the center fin receives heavy turbulence coming off the right fin and the right rail. Yet, the right fin in the control set always had a significantly lower mean resultant force and least negative direction, suggesting degraded performance due to interactions with turbulence from the surfboard’s side, or rail. Ultimately the detailed flow analysis also reveals that the whale-inspired fins provide a “damping effect” to the turbulent flow meaning less turbulence is affecting the maneuver.

Ventillation effects on ride experience

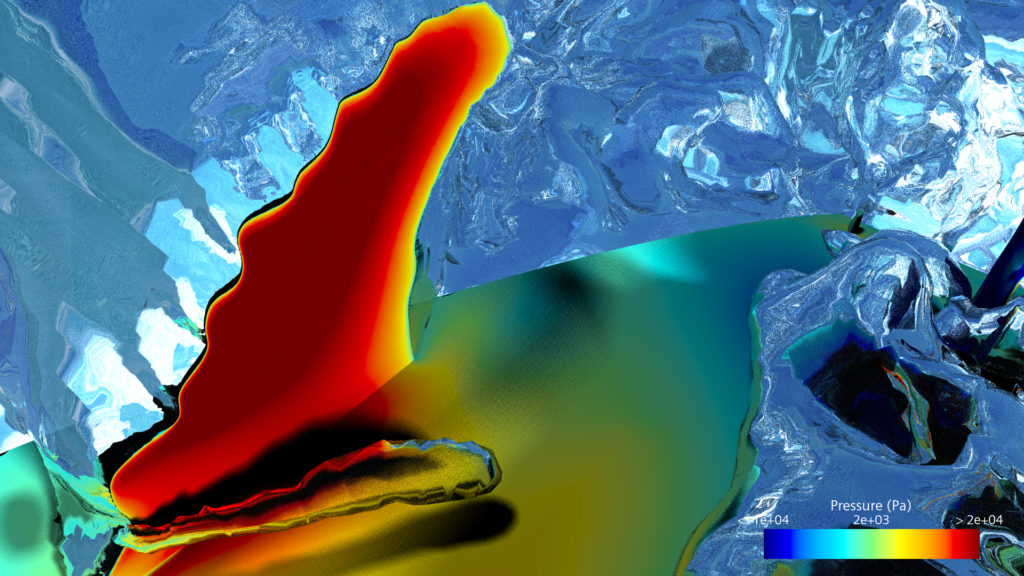

In addition to the turbulent perturbation of the water, the CFD proves how ventilation i.e., air mixing with water also appears to occur along the right rail, impacting the fins towards the end of each turn. Ventilated flow is turbulent, but more importantly its density is highly variable, which can further significantly impact a fin’s lift characteristics.

Understanding those fluid mechanics finally allows the designer to understand how the whale-inspired fins are able to produce the lowest force variability, up to 27 percent less than the control fin. The ultimate validation came from a skill level eight surfer, during the field testing. Right after he did a turn on his board equipped with the standard fin, the wave caught up to him and he fell off. “After he didn’t make that heat”, David explains, the guy came over to me and said “Man, if I had that whale fin I could have kept going!”.

In conclusion, even though a perfectly flat water surface does not represent real wave breaking conditions, CFD results matched well with field research to predict relevant trends. In a first pilot project the engineers proved how simulation truly helps to confirm what surfers feel – and even understand why they feel it from an engineering perspective. “This is the first time ever validation of surfboard CFD riding the wave.” David concludes “and CFD matched field results” Luca adds with a smile.

Beyond flat waters – The digital Teahupo’o

But Luca and his team at NablaFlow want more for their CFD models, they want a wave and they want the board moving on that wave.

Ten years ago, this was not even thinkable. But these things are possible today.

Luca Oggiano

So, Luca took his Laptop and Simcenter STAR-CCM+ and started to replicate none other than Teahupo’o, the legendary wave on the southwestern coast of the island of Tahiti, and one of the most famous yet most dangerous surf spots on this planet. The goal is clear: Even more realistic CFD models and conditions for board and fin testing delivering even more realistic insights. Detailed insights that not only qualitatively match the experimental data but truly predict the ride of the wave and reveal the details of board-wave interaction in various realistic maneuvers.

And while his first attempts are still limited to a linear prescribed motion of the surfboard, the ride of the digital twin of Theaupo’o already delivered some initial unexpected insights. Looking at the three fins – central, crest side and thrust side fin it turns out that in the tunnel “it is the thrust side fin that is taking all the beating”. Luca explains “This is something I would not have expected. In all honesty I would have expected the wave side.”

Riding the digital wave

Asked about the future, Luca says “I see a very bright future for the sports of surfing. In this specific moment there is a synchrony of events. Everything is at the right place.”

Surfing is getting into the Olympics, wave pools are popping up all over the world, there is technology available like additive manufacturing and advance in-situ data mining. And of course, CFD but also Finite Element Methods to simulate fluid dynamics, stiffness, damping and fluid structure interaction of the surfboard will be a continuously important game changer.

And CFD will not stop at the board, digital wave pool design and tuning will be a completely new application area. And finally, when it comes to equipment and you compare to other sports like cycling, surfing is a complete virgin field.”

Luca Oggiano, Surfer and Engineer

So, clearly, it’s time for surfboard industry to ride the digital wave!

If you are now keen on riding the digital wave, more about multiphase CFD simualtion in Simcenter STAR-CCM+ can be found on our Website and in these insightful blogs on faster VOF simulations and Hybrid Multiphase.