Teaching CAE 3D simulation with Simcenter

Advice from professors and professionals around the globe teaching CAE 3D simulation with Simcenter

A customer recently told us that some people in her organization think that the CAE world is sorta a “hocus-pocus” land where engineers just wave a magic wand and voilà, everything is OK. Ask anybody working in CAE today and certainly, those in academia who teach CAE every day and they will tell you differently. Behind all that “magic” is a solid understanding of engineering processes and lots of hard work modeling complex issues. So you can guess that getting students to really understand this “magical power” of CAE simulation and how to use it properly in a collective simulation and testing engineering environment can be a challenge.

One of the main reasons is that CAE simulation covers a large and growing set of engineering disciplines. And CAE simulation and the world of digital twins are moving towards an interdisciplinary approach rather quickly. So how do you teach something that is constantly evolving to industry needs? We’ve asked professors who teach Simcenter from all corners of the world to explain how they handle the challenge of teaching in the evolving world of simulation.

Understanding the basics

Ask any expert and they will say that, first and foremost, understanding CAE requires a solid understanding of basic engineering methods, mathematics, and physics before diving into the details. So starting Engineering 101 with a crash course in Simcenter CAE simulation solutions is not the ideal place to start.

“We start with the basics, which is rather conceptual. Typically, the only software interaction might be a bit of scripting in MATLAB for the first year. But towards the end, we lift the cloth so to speak, and show the undergrad students what they would use later on when they start to deep dive into the subjects,” explains Dr. Bert Pluymers, Senior Industrial Research Manager at KU Leuven’s Department of Mechanical Engineering. “For this, Simcenter is the standard for all courses we teach. This includes both Simcenter simulation and testing. It’s all Simcenter.”

Where some of Simcenter started: Leuven, Belgium

The fact that Simcenter is taught at the KU Leuven as a standard isn’t surprising. Historically, KU Leuven has always had a close relationship with Siemens and Simcenter. (Editorial note: Some readers would remember that part of what is Simcenter today was originally owned by LMS, a small Belgian spin-off from KU Leuven.)

“Later, as the students advance, we teach data acquisition and full-blown 3D simulation. We are talking about courses on finite element modeling, noise control engineering, and vehicle dynamics to name a few,” explains Dr. Bert Pluymers. “In the end, we are preparing students to take a role in industry at some point and they will have to use Simcenter and Simcenter-related tools. It is our duty to get them familiar with this.”

Besides building a good engineering knowledge base, one of the challenges is teaching problem-solving and how to use the Simcenter simulation tools optimally to solve engineering problems.

Adds Dr. Bert Pluymers, “CAE and simulation has become quite interdisciplinary these days. To solve real engineering problems, it is more interesting to have students build up digital twins in a lab using the tools that industry uses. It is important to let the students really see how these interdisciplinary elements work together and how the Simcenter idea of 1D, 3D and testing works. This is really an enabler. I might add that Simcenter Amesim is quite popular with our student projects as well as our master thesis projects, including those we do together with Siemens as a partner.”

As Dr. Pluymers said, students using Simcenter 3D tend to be working in a masters or more specialized environment. That being said, it isn’t just about the nitty gritty details of stress analysis or electromagnetics or CFD or multi-body dynamics, CAE used correctly in a collective engineering process can be a valuable tool to optimize product design quickly.

Onwards to Brookings, South Dakota, USA

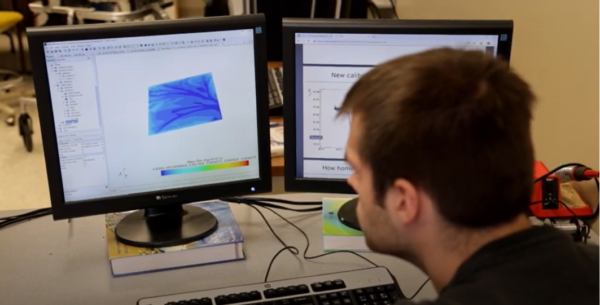

Let’s jump over from Leuven, Belgium to Brookings, South Dakota, USA and Dr. Stephen Gent, Associate Professor of Mechanical Engineering, South Dakota State University. He has been teaching thermal fluids engineering and applied CFD for more than 9 years to undergrads and graduate students and Simcenter STAR-CCM+ is the primary tool he promotes.

“One of the main challenges teaching the simulation tools is being able to get the students to pick up the technology behind the tool and to be able to turn that back to what they have previously experienced during their studies as well. Simcenter STAR-CCM+ has been really good to work with because they have a lot of tools and resources that we can use in our courses to help enlighten our students,” explains Dr. Stephen Gent, Associate Professor of Mechanical Engineering, South Dakota State University.

His first and second year students, who may be part of the engineering program or another STEM discipline, are introduced to Simcenter STAR-CCM+ in what he refers to as a “crash course” in the software.

“Within 2-3 weeks, after very intense training, they are able to develop initial models and get some reasonable results,” he adds. “They gain confidence in using the tools and build up their skillsets and expertise from there.”

Watch the full interview with Dr. Gent here.

Dr. Gent is also quick to point out that it isn’t just about being a wiz with a software package. It is all about being able to use the tools in a way that is hands-on. This is why more and more colleges and universities are combining theory with active practice in the lab, more advanced in-house internships with industry partners and the ever-popular student racing project. Which takes us even further west than South Dakota to…

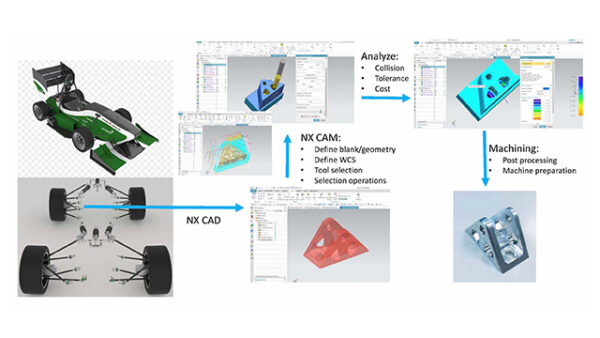

Xiangyang, China and Formula Student China

So while the rest of the world was rather hunkered down this year, let’s turn our attention to China and more specifically the 2020 Formula Student China event, which was held in Xiangyang, Hubei province from November 9th to 14th, 2020. Around 170 university-level SAE Formula Student racing teams competed in various challenges such as technical design presentations and racing on the tarmac. There were 67 Formula Electric teams, a record 30 Formula Autonomous teams, as well as 67 Formula Combustion teams.

Student teams were introduced to a wide range of Siemens tools including Simcenter Star-CCM+, the de facto standard tool for the simulation and analysis of aerodynamic packages and cooling systems for Formula Student worldwide (As well as major professional Formula One teams, we might add.) If you want to learn more about Siemens at Formula Student China, you can read the full blog here.

Onwards to New Delhi, India

With the global adaptation of digitalization this past year, things are changing at lightening speed. So let’s scoot over to New Delhi, India where Prof. Anoop Chawla has some more specialized experience teaching an industry-standard Simcenter tool. Prof. Anoop Chawla, a Henry Ford Chair & Professor at the Department of Mechanical Engineering at the Indian Institute of Technology in New Delhi explains,

“My students were excited to get an exposure on specific tools. For example Simcenter Madymo is widely used in the industry. They could use this to effectively understand multi-body simulations, their use in occupant safety design and their advantages vis-à-vis full finite element-based simulations. Overall, the experience they gained from that experience software would serve them well in their engineering careers ahead.”

More resources Simcenter 3D CAE solutions

So to wrap this up, the Simcenter Learning Platform is a great resource for students and professors alike. You can find Tech Tips video library, knowledge based articles, free curriculum downloads for certain product lines, an open forum as well as the learning advantage platform for digital learning.

Besides quick reviews of Simcenter for CAE simulation tech tips videos to integrate into curriculums, engineering professors can get students introduced to the basics with free curriculum packages, like this one of Simcenter STAR-CCM+ and Aerodynamics. Following the curriculum guidelines, students can access short lessons utilizing video and assessments as well as interactive lab exercises which let students navigate through at their own pace.

Teaching Simcenter CAE simulation solutions: Digitalization platforms, support tools and yes even a textbook

Digital platforms, other support tools (including yes even an old-fashioned text book) and industry experiences are opening up the world of 3D CAE simulation with Simcenter to students from all over the world. They are getting first-hand experience and exposure to this industry standard and this, in many cases, translates to invaluable work experience. We’ll hear more about this shortly in our upcoming blog to wrap up the Simcenter Academia series this academic year.