Technology Issues and Solutions Behind CAD/CAE Integration

Imagine you use a dial-up internet connection. After you learn broadband offers a faster connection and high-speed internet, which allows you to view larger files with more ease, you decide to switch. Without a cable box or DSL, though, you won’t be able to reap the benefits of broadband.

While the above metaphor demonstrates the point, it is a little over-simplified for the case of CAD and CAE integration. You might encounter software that promises to integrate the two, but doesn’t provide a truly integrated experience. It would be like if your broadband connection only worked halfway, leaving speeds lagging behind what they could be.

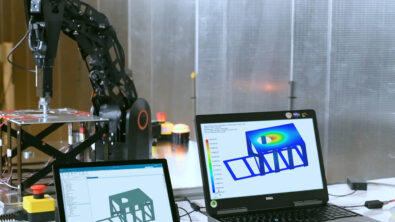

This is what happens when software systems use piecemeal efforts. As Scientific Computing World notes, some CAD vendors have purchased simulation packages in an attempt to integrate their systems. Siemens, however, has developed CAD and CAE technologies alongside each other for more than 40 years. Siemens’ NX CAE is a multidiscipline simulation solution that is built on the same platform as NX CAD, thereby delivering a truly integrated experience.

One of the most common technological issues encountered with piecemeal integration is information loss. Information is lost when data is exported from one system and imported into another through a neutral format. Time is lost when an engineer has to learn an entirely new user interface just because they are performing a simulation task rather than a design task.

NX eliminates such inefficiencies by providing seamless workflows that take a user from design creation to validation in a consistent graphical environment that they know and understand. Needless data transfers and sources of manual errors are eliminated. Providing product development teams with an integrated environment like NX can also encourage earlier application of simulation, or simulation-driven design to become reality.

But, the value of integration goes beyond the benefits outlined above. We’ve talked about how NX Synchronous Technology and associative geometry enable integration. Simplifying and automating the process of creating CAE geometry is another benefit of NX.

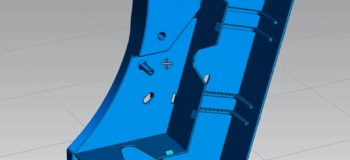

Unnecessary features such as holes or gaps may not affect the CAD design, but they have a huge impact on the time it takes for simulation. Analysts spend a significant amount of time defeaturing and cleaning up CAD geometry in order to perform analysis. Analysts may also spend a lot of effort on generating mid-surface models that are more efficient to mesh.

Simplifying CAE geometry preparation is just another way that CAD- CAE integration in NX improves your workflow, so you can focus on results.

-Amy