Is your heat exchanger stressing you out?

Robert Yerkes and John Dodson first developed a relationship based on empirical data that human performance increases with stress, but only up to a point. Further stress leads to decrease in performance, giving a classic bell-shaped curve. A constant amount of stress can then lead to chronic fatigue.

Heat exchangers are no different. They go through possibly millions of transient thermal cycles. The cycling thermal changes cause stress in the heat exchanger material, leading to fatigue.

Thermal fatigue of brazed aluminum heat exchanger (BAHX) was identified by the U.S. Chemical Safety Board (CSB) as the main reason for the 2016 Enterprise Products Gas Plant Explosion in Pascagoula, Mississippi.

“More than 500 gas processing facilities operate across the country and the use of similar heat exchangers is common. Extending the life cycle of equipment at these facilities requires more robust inspection protocols. Operators shouldn’t take the risk of waiting to find a leak because, as this case demonstrates, that leak could result in a catastrophic failure.”

According to the Chemical Safety Board:

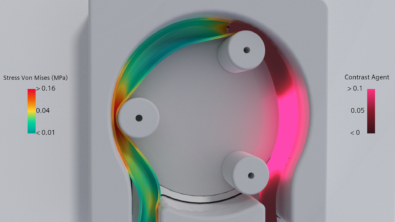

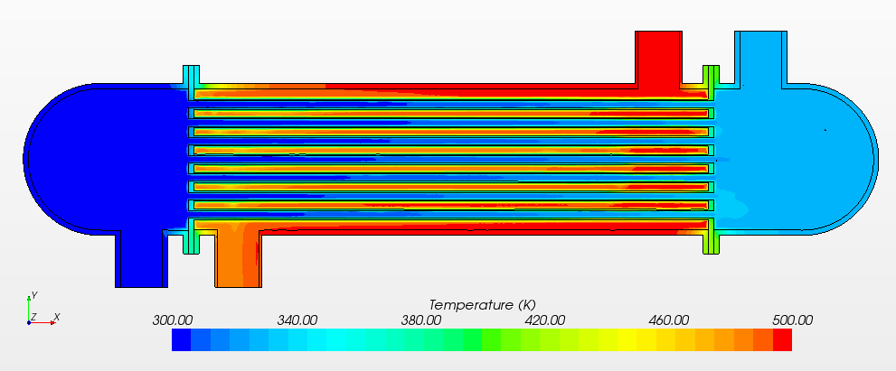

Fluid Flow simulation

Performing fluid flow simulation with Simcenter STAR-CCM+can give a understanding of the thermal behavior of the flow inside a heat echanger. Often time, it might give insights to improve the flow behavior to enhance the thermal performance: parameters such as tube spacing, baffle spacing, entry/exit nozzle spacing, internal flow diverters can make a huge impact on the performance.

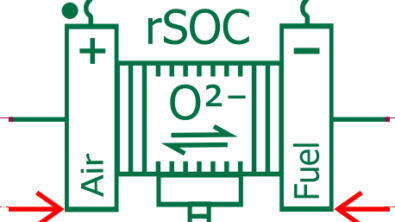

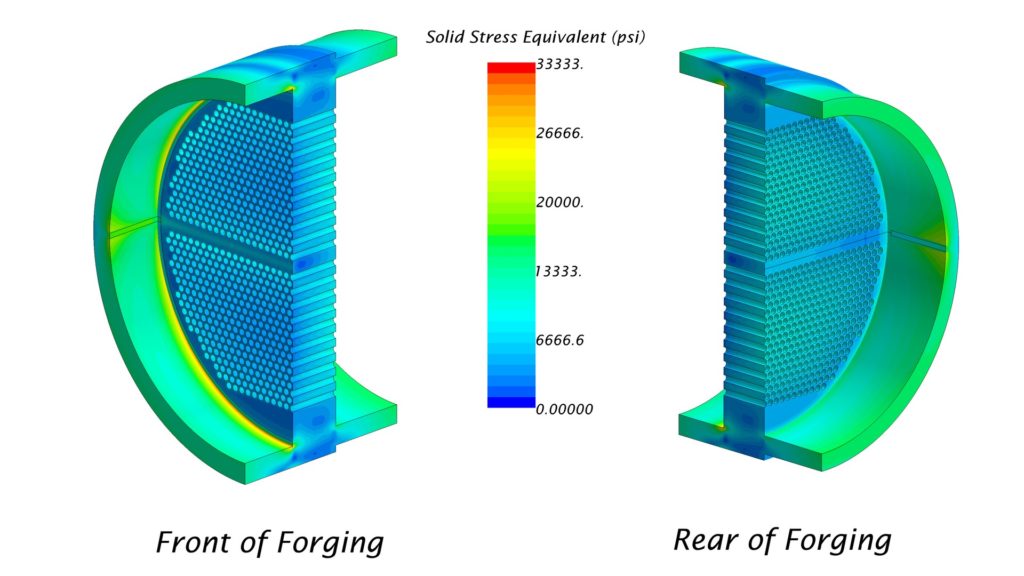

Stress Simulation

But the story doesn’t end here. STAR-CCM+ allows you to seamlessly transfer the thermal imprint to the solid parts of the exchanger to perform a full fledged stress analysis. This allows you to evaluate the design not only for the process performance but also for the mechanical integrity

Don’t let fatigue and stress of your heat exchange equipment impact your stress levels. If you would like to know more about Aspects of Heat Transfer in the Process Industry: Design, Analysis and Troubleshooting of Heat Exchangers and see a real life case study, you can learn more by watching this webinar.

https://www.plm.automation.siemens.com/global/en/webinar/heat-exchanger-cfd/68787