[Webinar] Make your heavy equipment machine stronger and sounds better

For any operators, the durability, efficiency, and comfort are key to be sure of when investing in a new heavy equipment machine. Therefore, agricultural, construction, and mining equipment manufacturers are under constant pressure. They have to deliver machines with ever-increasing power, uptime, and productivity in harsh environments while meeting market expectations such as emissions reduction targets and regulations standards. All of that without compromising machine comfort, and durability expected from the end-user. As a consequence, it is crucial for the OEM to test, validate, optimize, and certify heavy equipment machines within these constraints. Those are shorter testing cycles, conflicting performance requirements (such as durability, operator comfort), growing product complexity, and reduced costs.

However, it still remains challenging for the machine testing teams to execute all the testing needs in the most efficient and optimized way. Except if they are equipped with the correct tools., how I explain during the on-demand webinar: Increasing the test efficiency of your machine’s durability and NVH performance using a single platform“. Find out more below or scroll down to directly access the link to register.

Comply with regulations: minimum ticket to sell

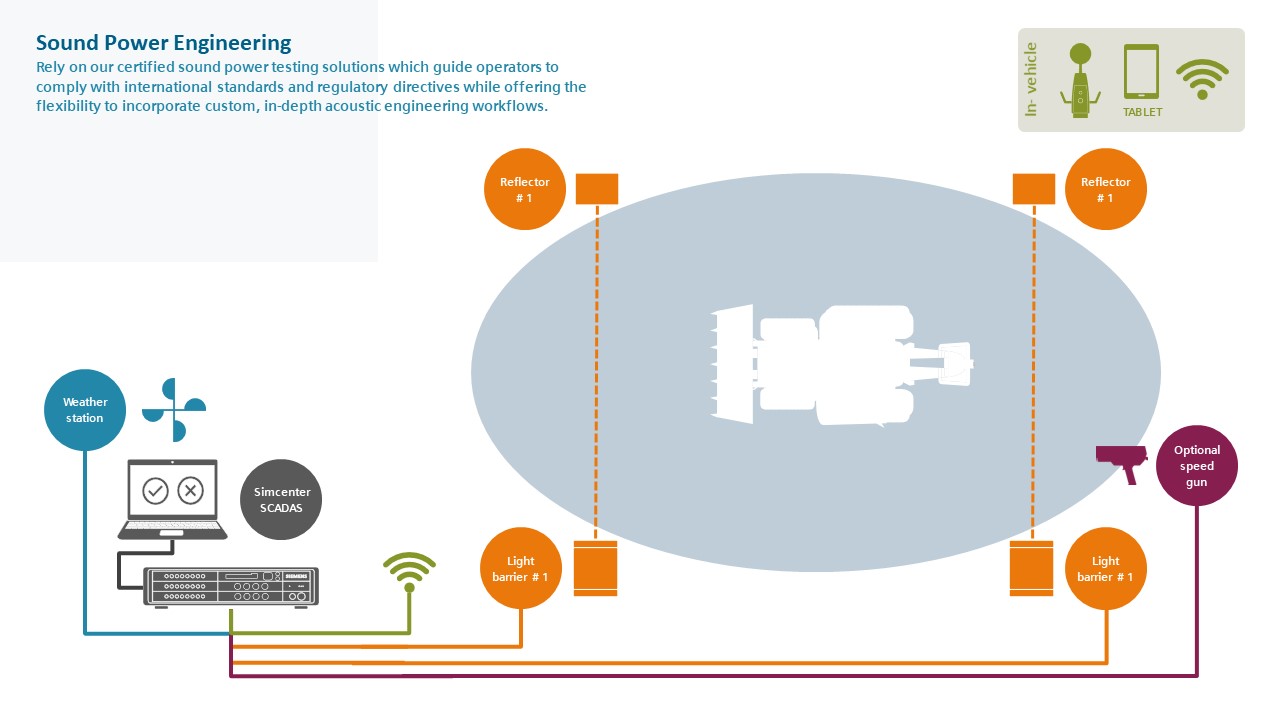

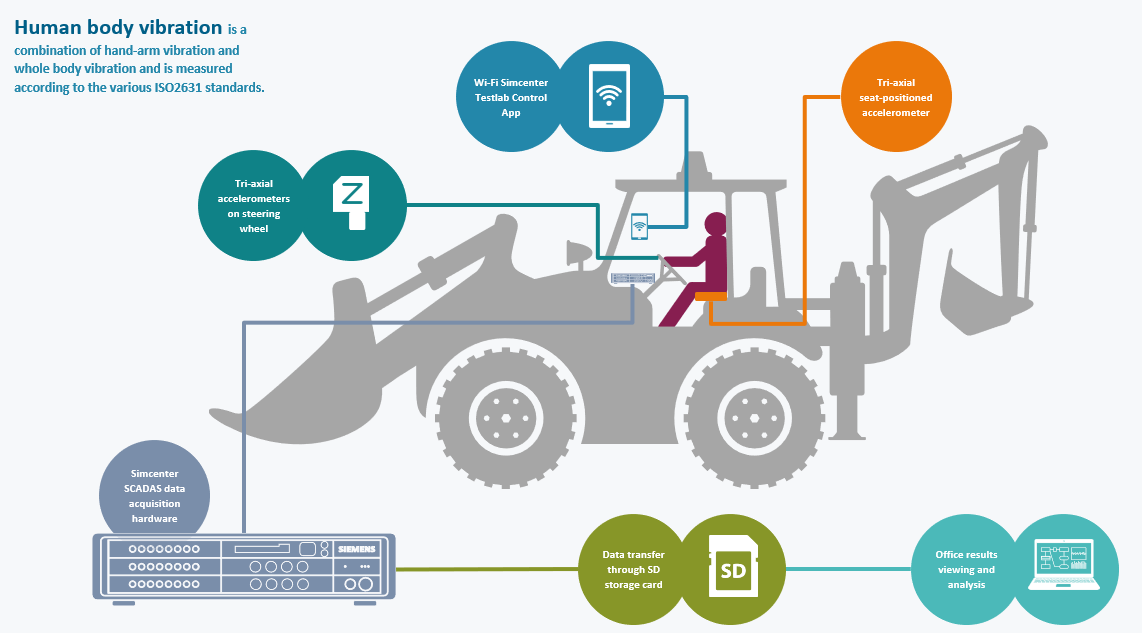

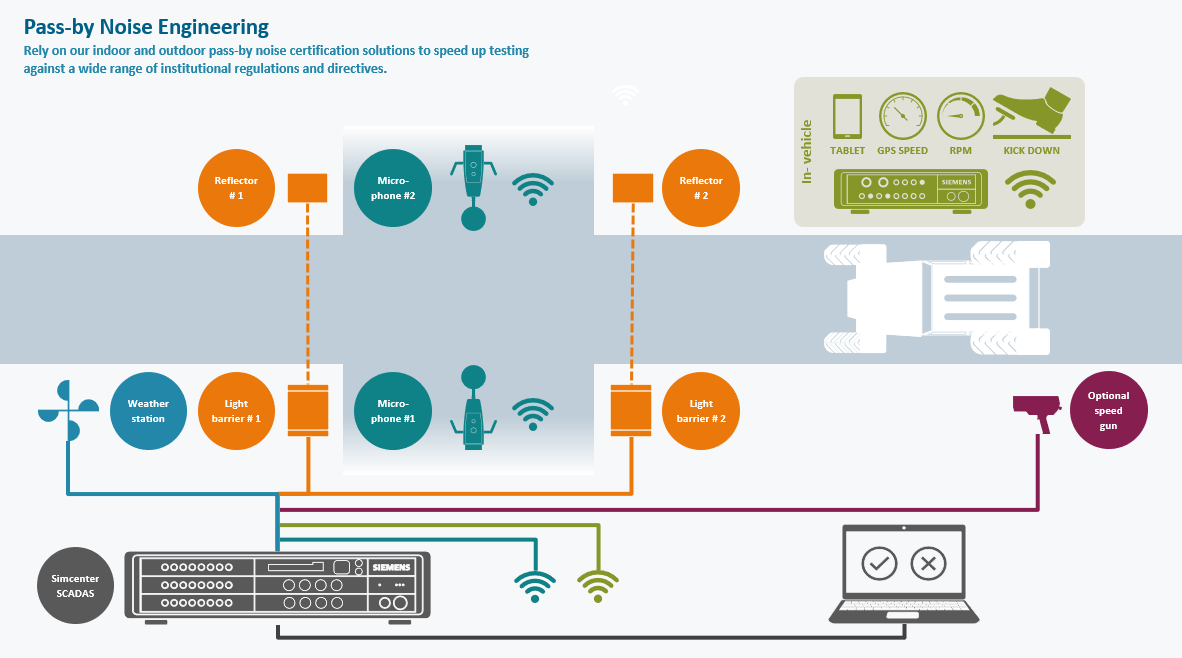

To sell a heavy equipment machine in Europe, manufacturers need to comply with ISO certifications. It is about Sound Power, Human Body Vibrations and Pass-by noise depending on the machine type. These regulations are not mandatory for EU only, since many countries from different continents follow the same requirements. In such a complex certification context, the manufacturer can question: “how can I cover these different ISO certification tests in very limited development time in the most efficient way?“

Sound Power measurement of an earth moving machine

Human body vibration testing (Hand-arm vibration and Whole-body vibration)

Pass-by noise testing of an agricultural tractor

Heavy equipment durability testing: make sure it doesn’t break!

Once manufacturers made sure the heavy equipment machine complies with ISO certifications, they focus on another key attribute the machine reliability.

To bring a competitive machine to the market, OEMs have to ensure machine structural integrity and durability, for any type of environments even the tougher.

Testing example: John Deere 8000 Series Forage Harvester (source: https://www.youtube.com/watch?v=9t2arqcI3z8)

Durability performance is highly dependent on machine design, field conditions (market to sell), customer profile (usage, habits…) and operations. By considering all those criteria, the manufacturer ends up with very high complexity to care on structural integrity and durability.

Heavy equipment NVH and comfort testing: make it sounds better!

In the meantime, durability performance should not be improved at the cost of the operator’s comfort and safety. Parallel to excelling at durability evaluation, manufacturing designs must meet regulatory requirements of noise, vibration and harshness (NVH). This has to be done with an even improved situation of operator’s safety and comfort to gain a competitive advantage.

Designing top-of-the-line machines considers troubleshooting for NVH and systems engineering methods to predict the performance as early as possible.

Sound source localization helps you confirm working on the right problem

All these fundamentals bring us to a very generic need to test the heavy equipment machines against different needs in the most efficient and optimized way.

In this context, I propose to join a webinar on-demand I hosted about ‘Increasing the test efficiency of your machine’s durability and NVH performance using a single platform“. You can join here: How to reduce development cost and time of your heavy equipment without compromising on durability, efficiency and operator comfort

More in details you will see how you can:

- reduce costs up to more than 30% thanks to a single testing platform covering durability, NVH and comfort

- increase productivity by implementing smart test processes

- accelerate innovation by predicting the performance as early as possible

- improve collaboration by reducing gap between test and simulation

Questions or curious about further capabilities of Simcenter testing solutions?

- Visit our website: Heavy Equipment Performance Engineering or contact us.

- Follow us on the blog: bookmark that link

- Read another dedicated blog article about noise regulations: Construction equipment noise levels: How to meet regulations

![[Hyster Yale] How to convert a conventional lift truck into an electric truck?](https://blogs.stage.sw.siemens.com/wp-content/uploads/sites/6/2021/05/HY_Teaser-350x160.png)