What’s New in Simcenter 3D 2020.2

Chronic chaos is not a suitable environment for accomplishing complicated tasks with multiple variables and moving parts. Meeting complex engineering challenges requires an efficient and orderly approach. However, having the right tools and framework can make a world of difference in how quickly and faultlessly these challenges are met. This is why product engineering teams need a unified and shared platform for all simulation disciplines. Simcenter 3D offers such a platform with leading-edge analysis tools, more productive workflows and demonstrably consistent results. With Simcenter 3D 2020.2, we make it that much easier to meet these challenges by continuing to enhance on four unique strengths:

| Multidiscipline Integration | Perform more simulation types from an integrated environment |

| Faster CAE Processes | Spend less time modeling, and more time on engineering |

| Openness and scalability | Simcenter 3D can be adapted and integrated into workflows as needed |

| Ties to the digital thread | Connecting simulation to your development process |

Multidiscipline integration

Introducing Simcenter 3D Materials Engineering

| Materials are being introduced into the market at unprecedented speed. A new material can be a new chemical, or a combination of existing materials, and to that end the number of possibilities becomes almost infinite. Novel manufacturing processes such as 3D printing are enabling new shapes, but make material microstructures much more variable and complex. In this release, we launch the first phase of integration of the Simcenter Multimech solver, acquired with MultiMechanics in late 2019, with Simcenter 3D to create a new Simcenter 3D Materials Engineering product. This ultimately gives you the ability for virtual material characterization to simulate how non-uniform materials behave and accelerates product development by predicting failure in advanced materials. |

Vibration Fatigue

Successfully predicting where failure will most probably occur is critical for good product design, safety, regulatory or other damage related catastrophic issues. New in 2020.2 is the Harmonic Event that handles frequency based loads like sine dwells and sweeps and any combination of them. This applies to scenarios such as the wind force acting on a turbine or wave load on offshore installments. Compared to a computationally more expensive time domain simulation, this is an efficient fatigue analysis approach.

| Highlights of other new investments for multidiscipline integration include: | |

|

Faster CAE processes

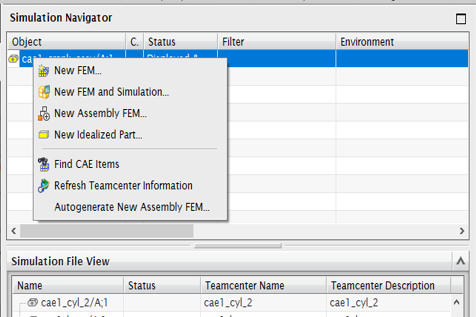

Seamlessly create FE assemblies from product configurations in Simcenter 3D 2020.2

Simcenter 3D software can be used in a managed environment with Teamcenter® software for integration. You can create, store and access your product simulation data in a Teamcenter database. It combines the power of Simcenter 3D for efficient simulation modeling with the power of Teamcenter in storing and retrieving data in a controlled fashion.

In this release, we have streamlined the Assembly FEM (AFEM) creation from product assembly configurations in your data management system. The Structure Map capabilities of Teamcenter Simulation Process Management can be run seamlessly from within Simcenter 3D. While the automation is executed on the Teamcenter Simulation server, you always stay within Simcenter 3D Pre/Post. This helps strengthen the collaboration between design and simulation.

Restart Multiphysics Thermal-Structural Solutions

Now you can easily restart the structural portion of a coupled thermal-structural multiphysics solution from a structural preload. Many multiphysics models start with the same structural preload conditions; simplifying the restart reduces the solution run time and allows more design studies to be performed in less time.

Open and scalable

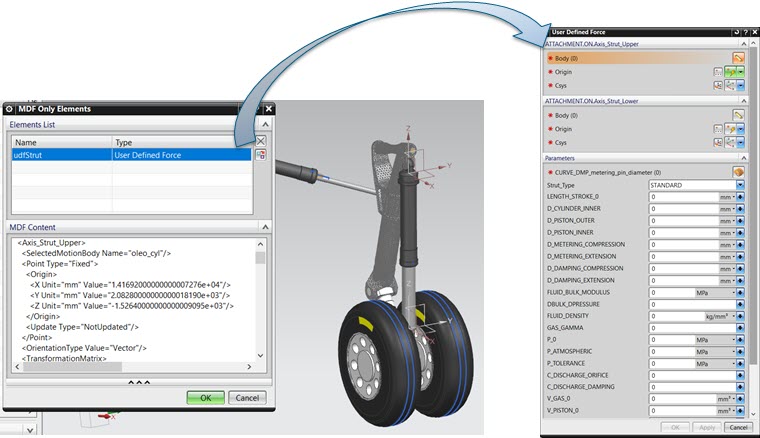

Customized Solver Subroutines

In 2020.2, Simcenter 3D Motion and Simcenter 3D Specialist Durability offer a unique openness to users who wish to customize solver methodologies. Users can create and write their own solver force function, fatigue solution or customize the existing solver routines for use during computation.

Examples include user defined

- Force formulations into the motion solver through a dedicated user interface

- Fatigue method and methods to define local fatigue parameters

- Mean stress influence methods

- Damage accumulation rules

Manage Material Data in the Right Format

| Recent improvements in Teamcenter make it straightforward to manage material data and export that material data in the right format for your simulation tool – whether that’s Simcenter 3D or a third-party CAE tool. The latest versions of Teamcenter and Active Workspace allow analysts to leverage enterprise material definitions (single source of truth) in simulation workflows by exporting material data to solver specific formats such as for Simcenter Nastran, Abaqus, Ansys or others. |

Ties to the digital thread

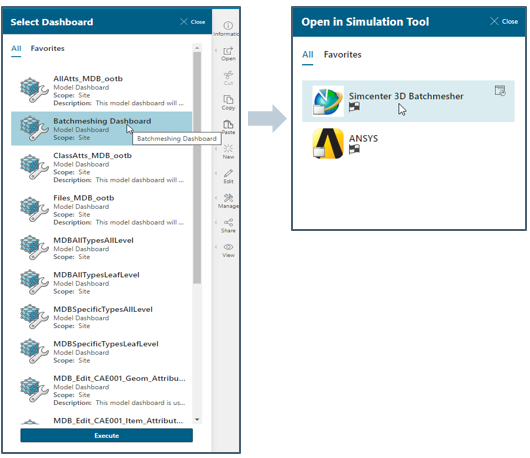

Simulation Dashboards

Simulation data management is key to keeping your simulation processes tied to the broader digital thread for product development, and Simcenter 3D’s connection with Teamcenter is how we achieve that. In Active Workspace, simulation dashboards provide a clear view of the status of the models and analyses. The latest release can execute simulation dashboards with added flexibility by allowing different input methods such as query, BOM, folder and selected objects.