What’s new in Simcenter System Simulation solutions 2022.1

The Simcenter System Simulation release 2022.1 is here! It delivers the next developments to help you build a comprehensive digital twin strategy and ensure state-of-the-art solutions. Our teams have worked hard to answer the industry challenges posed. New features now allow you to model the complexity of any system, safer and faster.

New enhancements in Simcenter System Simulation solutions 2022.1 aim to help you:

Model the Complexity &

Explore the possibilities

Our solutions allow engineers to model the complexity and explore the possibilities of any system. New capabilities allow you to model all the relevant physics such as structures, flow, electromagnetics, thermal, and much more.

Electrification and vehicle dynamics

The first set of applications that we improved were Electrification and vehicle dynamics. We prioritized this due to the recent industry challenges.

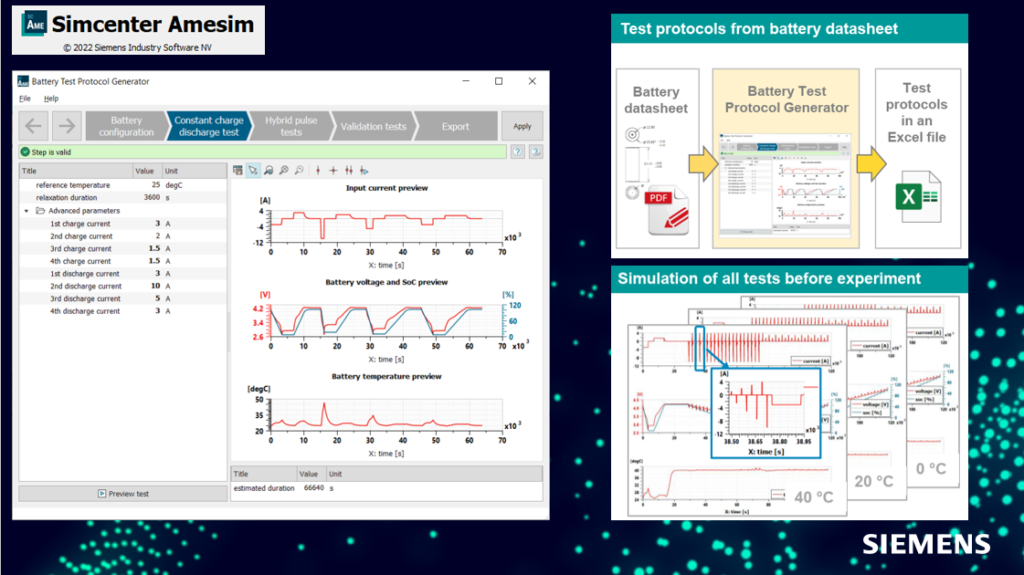

For test engineers who need to perform battery characterization tests, we designed the new Simcenter Amesim battery test protocol generator. The battery datasheet information generates the experimental test protocols. These test protocols are exported directly into an excel spreadsheet, ready for the test technician.

With the tests completed, results can then be processed into the Battery Identification tool for a proper model identification of the battery’s electrical and thermal behaviors.

In Simcenter Amesim 2022.1, we have created a heat exchanger assistant app that offers a complete workflow to build your heat exchanger model with interactive tools to set the geometry and thermal correlations and an automated sketch generation. This means a clear, quick, and robust workflow to create, calibrate and size the heat exchanger model.

We have also updated the proton-exchange membrane fuel cell component model and vehicle integration to widen the design exploration capabilities and facilitate the first model architecture set-up. This is particularly helpful for fuel cell system engineers who need to design, validate and optimize the fuel cell stack balance of plant. Indeed, the updated component helps to quickly evaluate alternative components and control strategies by ensuring the right balance between performance, vehicle range and thermal management is achieved.

Aerospace, defense and marine

The capabilities to study flight dynamics have been extended with two new features. From one side, we implemented a new look-up table-based aerodynamic submodel for 6 degrees of freedom flight dynamics. This allows system engineers to assess any flying conditions, including those over and beyond the overall flight envelope. The look-up table approach will also enable engineers to re-use advanced external aerodynamics CFD results – done through Simcenter STAR-CCM+, for instance – within system-level simulation assessing flight performance with a given propulsion system hybrid or conventional.

The second new feature allows system engineers to model flight perturbances on vehicle dynamics like turbulence or wind gusts and, therefore, validate guidance, navigation, and control algorithms early in the program cycle.

For the marine industry, we have introduced a database of sea routes with three levels of representative weather conditions. This comes with the capability to perform multi-stop and restart along the sea route.

Marine engineers can assess ship performance in realistic conditions with this new capability. With detailed and accurate information on power requirements, they can explore different and innovative possibilities in terms of control strategies and fleet management.

Green energy

With climate change concerns increasing and a renewed focus on sustainability, green energy is becoming an important topic. Green energy applications require the development of new technologies. This includes the use of specific fluids like hydrogen, carbon dioxide and ammonia.

For this purpose we have developed a new two-phase pipe that offers great flexibility to model different system configurations. Thanks to the conjugate heat transfer capability it is possible to model the energy transfer between the fluid inside the pipe and different external surfaces. In addition to this, the drift flux model allows modeling of the relative velocities of the liquid and vapor fractions accounting for slip ratio between the two phases and for the relative volumes of vapor and liquid.

Another important component for system engineers involved in the green energy sector is the multi-path plate-fin heat exchanger for liquid, gas and two-phase fluids. In Simcenter Flomaster 2022.1, we have introduced a modular design approach that allows engineers to easily create heat exchangers with multiple paths. This means that they can evaluate different design options. Besides this modular approach, we also offer pre-built components to provide examples of how multi-path heat exchangers can be built. In this way, engineers can quickly build a library of custom multi-path plate-fin heat exchangers to be reused during their daily work.

Go faster &

Stay integrated

Our solution tools exist within an ecosystem that includes many different software applications, therefore we design solutions to be open and support industry standards. We significantly invest in integration and synergies with tools in the wider Simcenter portfolio and with other solutions within Xcelerator.

Deployment

For a Simcenter Amesim model owner who wants the simulation parameters to be fully controlled without mistakes and well visualized by the model consumer (final user), Simcenter Webapp Server 2022.1 offers multiple parameters visualization such as switches, buttons and sliders. This means that the model consumer can easily change the model parameters in a simple, visual and efficient way and stay secured in the min/max values ranges configured by the model owner. In this way, any risk of simulation mistakes is avoided.

Internet of Things

In this new release, engineers that want to use simulation during the operation of a system can use the new MQTT connectors to connect Simcenter Flomaster to the cloud. This enables them to create a two-way connection with a data broker that can publish information to an IoT-ready platform. For this purpose, Siemens offers Mindsphere where advanced dashboards and historic trends can be quickly analyzed. This provides system operators with additional information through virtual sensing and performance analysis and results in predictive maintenance being undertaken before an issue can arise: overall reducing plant downtime, maintenance costs, and operational expense.

These are just a few of the many new exciting features in Simcenter System Simulation solutions 2022.1,