Why perform multi-axis vibration testing?

Multi-axis vibration qualification testing: why bother? Why is this last step in a product development process an important one? And why do renowned universities like the University of Ferrara spend time and efforts to improve what seems like a well-known and well-defined procedure?

In short: to reduce the time spent on testing and increase the fidelity of the results.

What are vibration qualification tests?

They are an essential step in a product development process. They help ensure that the said product will survive the environmental conditions it is exposed to during its lifetime. In particular, they verify that a system, including its subcomponents, is able to withstand the vibrations in its environment during its operational life. As such, they are crucial to prevent premature damage or failure of a system in operation.

Why innovate the vibration qualification test procedure?

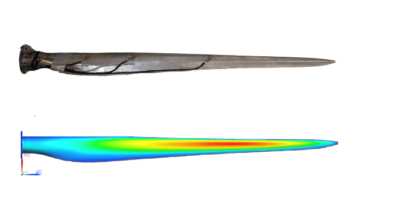

The main challenge of engineers is to replicate the of the system under test with a high degree of fidelity. The engineers are seeking to reproduce an often complex vibration environment in the laboratory. In real-life operational conditions, the vibration excitation of a structure (or complex system) is typically multi-directional.

But, in the laboratory, the system under test is usually placed on a shaker and excited along one to measure and understand its structural response. The current standard procedure for laboratory testing prescribes sequential single-axis tests (called sequential single-input single-output or SISO tests) to replicate multidirectional excitation. This practice has some technical and practical limitations.

- The time-to-failure ratio is grossly overestimated. Sometimes, test teams also witness different failure modes than the ones observed in real operation condition.

- Sequential single-axis testing doesn’t takes into account the interaction between the main excitation sources and paths. Moreover, it ignores the effect of the combined loading on the various stress/strain states and dynamic behavior of the structure.

- Multiple sequential tests are by definition lengthier than a single multi-axis test.

All the above are good reasons to look for a reliable and time-saving alternative. Multi-axial excitation, and more generally multi-input multi-output (MIMO) vibration control tests, are creating a buzz in the dynamic environmental testing community.

Pioneering research with multi-axis vibration testing

The University of Ferrara pioneers research about multi-axis vibration testing. It is the first laboratory in Europe to rely on a 3-dimensional shaker to perform the tests.

So, what does it mean concretely?

Have a look at the short video testimonial below.

Excited to learn more about MIMO and multi-axis vibration testing?

Read the full case study here or check the extensive knowledge base article: Multi Input Multi Output MIMO Testing.