With new EV cars, will powertrain NVH testing no longer exist?

by Ricardo Sales

How powertrain testing procedures will shape to develop greener powertrains

Have you ever had to explain to your family or friends what you do at your job? I know that for some people that can be very complicated without making the other person feel even more confused. Let me tell you what happened with me some time ago. In my last visit to my home country, I met with a good friend that I’ll call Mr. Wrong (to avoid exposing him). We went out for a coffee, and after explaining that I had been working with Noise, Vibration and Harshness (NVH) testing for powertrains, his first statement was: “Your job will not very important in the future, right?” Then, he continued… “Electric cars are quiet, right? So, if their powertrain is quieter, why would you have to test it?”

My reaction? I put a smile on my face, drank my coffee and started to explain to Mr. Wrong why he was… wrong in his statement.

Is it really a silent drive?

I invited him for a drive in a hybrid vehicle that I rented for some days. It was a nice car, but I knew I could prove my point while driving it around.

First, I started by showing him the “new noises” present in these types of vehicles, but with a focus the noises linked to the electric powertrain. We went on the road and while doing a first acceleration I asked him “Do you hear this sound? Like a tonal (and very annoying) sound?” Then, I started to push the brakes and asked again if he could hear that new noise too. Lastly, I drove at high engine speeds so I could show him a famous sound that is more prominent in electric drive mode: the gear whine noise.

The first sound was the tonal noise coming from the inverter. This is a device that converts DC power to the AC power used in an electric vehicle motor . The second was the sound generated by the gearbox while regenerating power during a braking event. Finally, the gear whine noise caused by vibrations generated by gears as they mesh; a result of imperfections caused by design, loading, temperature effects, and manufacturing variations.

Quieter but not silent…

Mr. Wrong felt at that moment that he could be wrong… I started to explain to him how the engineering behind powertrain testing development is changing, keeping my job important, and not only important, but also more exciting!

Powertrain testing development is adapting its procedures and testing methodologies in order to cope with these new challenges. Manufacturers aim at reducing the number of physical prototypes both for engines and cars. This means that being able to predict, through simulation supported by testing, as many functional attributes as early as possible in the development is a must to front load the development process.

How hybrid and electric vehicles’ development is evolving

Mr. Wrong was excited about the conversation and asked me: “What about these hybrid vehicles? Are they any different?”

In the first EVs, a lot of trim was used to “solve” some of these acoustic problems. However, this solution is not ideal as it can be costly and it can increase the vehicle’s weigh (while the goal is always to reduce it). Engineers are being pushed to solve these issues during the development cycle. For that reason, new methods and ways of testing need to be implemented into the process. All of this with the extra complexity represented by new NVH behaviors and the need to adapt the measurement techniques to be able to acquire high quality data.

When it comes to the testing of a hybrid powertrain, there are a few things that are different with regular ICE engines:

- There are more than one motor/generator/engine that don’t necessarily run at the same or directly related speeds.

- Measuring RPMs in electric motors is not so straightforward and requires new methods.

- The high frequency noise from the inverter required new analysis tools, as they have different signature with the so-called “off-zero orders”.

- With electric motors are rather quiet (not silent), gear box noise (mainly gear whine) has become a bigger issue (as we experienced during our drive).

Mr. Wrong immediately said: “Powertrain testing procedures became much more complex and time-consuming!” And at that moment I felt that we were almost on the same page! 😊

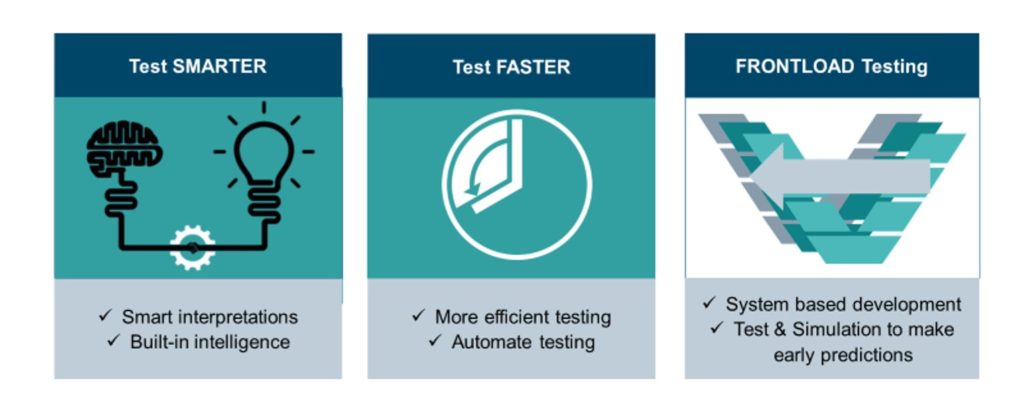

More complex yes, but not necessarily more time consuming. Engineers must test smarter and faster, and they really do that effectively.

ICE Powertrain: New control strategies for greener drivetrains

But what about the cars equipped with an internal combustion engine? Are the powertrain testing procedures unchangeable for these vehicles? Fortunately (for my job), the answer is no.

The constant push towards “green” powertrains with lower emissions, higher performance and efficiency, made it necessary to implement new control strategies for these powertrains. These control strategies (such as cylinder deactivation) have a negative effect on NVH, both from a noise emission perspective, as from a torsional vibration perspective. It has become extremely important to make the right trade-off or balance between different performance attributes in order to develop a good engine.

Mr. Wrong, who was at that point convinced, asked me how powertrain methodologies are evolving to support powertrain engineers during the development of new powertrains. I thought: “What a great question Mr. Wrong!”

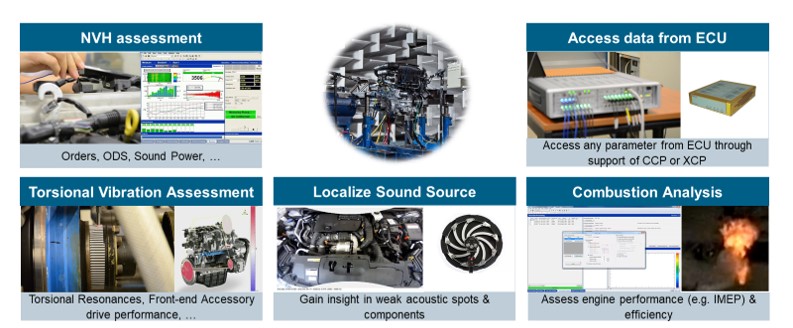

Powertrain testing procedures and development are adapting to be more efficient and bring more insights in all phases of the development. Engineers needs to test smarter and faster in order to cope with complex powertrains and their control strategies. It’s very important for the NVH engineer to go beyond pure NVH testing in order to balance the different attributes of the powertrain. All of this by unifying different data streams used for a variety of analysis engine power/efficiency/combustion, emissions, torsional vibration, noise, etc. Integrating them into one single data acquisition and processing system allows for analyzing the effect that one attribute has on another much easier, and supports the idea of being able to balance attributes effectively.

New technologies to boost your efficiency

The new available technologies are enabling new methodologies that have as big focus the contribution between test and simulation. By increasing this cooperation, the engineers will be able to front-load powertrain testing procedures in the beginning of the development cycle, which represent a huge gain in efficiency. Corecting problems and changing designs in the initial phases of development, while still working with system simulation models, is much easier and cheaper and ensures quality throughout all the phases of development.

High quality data is needed in order to validate the models used in these calibration activities. The focus must now be put on the quality rather than the quantity. We used test to validate the performance of the system, we now use test to feed CAE workflows.

Finally, innovative new methods and ideas are developed to predict the NVH behavior of powertrains even before their integration in the vehicle prototype. Component-based Transfer Path Analysis is a method that allows the transfer of vibration loads and acoustic radiation measured on a test bench to be reformulated into a form that allows them to be accurately used in a full vehicle simulation.

Finally Mr. Wrong was convinced and very quickly said he was “wrong”, and that I was “right”! After that, we changed the subject because, after all,… I was on vacation!

If you want to learn more about how this topic, please follow this free on-demand webinar.