How much do ‘U-Value’ good thermal insulation? Part IV

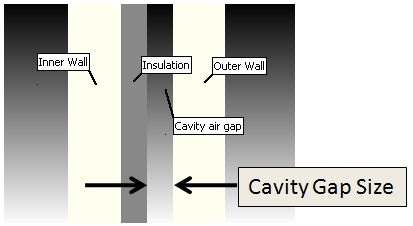

100mm block, 50mm insulation, 50mm cavity air gap then 100mm block make up an external wall that in theory comply with a building regulation overall wall U-Value of 0.3 (W/m^2K). This got me thinking about the 50mm air gap. Why 50mm? What if it was 75mm or 10mm? Stagnant air is a great insulator, a small gap would tend to stagnate the air and might improve, reduce, the overall U-Value. A large gap would have lots of air, ok, it’d be moving more freely but intuitively a bigger gap should make it more difficult for the cold to penetrate from the outside. With FloVENT at my disposal I’d be mad to consider actually building some walls and doing some physical testing. CFD based software simulation makes such studies achievable, quickly, easily and requires no building skills (thank goodness as I have none).

Someone once said that there’s no such thing as a single useful CFD simulation. It’s only when you start to look at variants of a model do you get the benefit of insight and understanding into why something behaves the way it does. Armed with this mentality I defined a parametric study in FloVENT’s ‘Command Center’ to set-up, simulate and compare the results of the effects of varying the gap size from 1mm to 100mm.

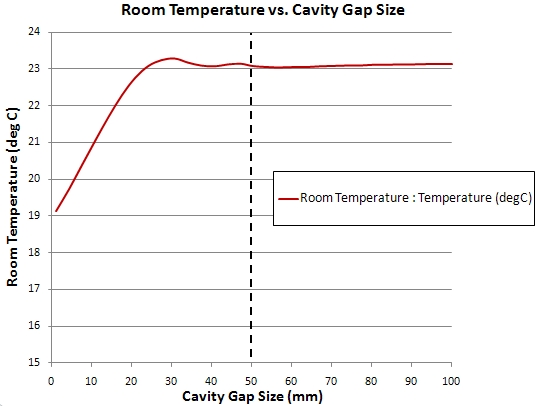

The most obvious parameter to look at to see the effects of the gap size is the internal room temperature. The outside ambient air is fixed at 2degC, a fixed power dissipation is set inside the room to represent a heater and the model set up such that that heat (W) can only go through the vertical external wall. Here’s the resulting plot of room temperature vs. cavity air gap size:

The vertical dotted line shows the original gap size. There is a small improvement in overall resistance at about a 30mm gap size but then the resistance goes down (U-Value goes up) dramatically as the gap size reduces. Most interesting though is the observation that after 50mm, there is no effect on the overall resistance. I’d like to think that numerous studies by a building control and regulation engineer arrived at this value and also that he was using FloVENT to do so!

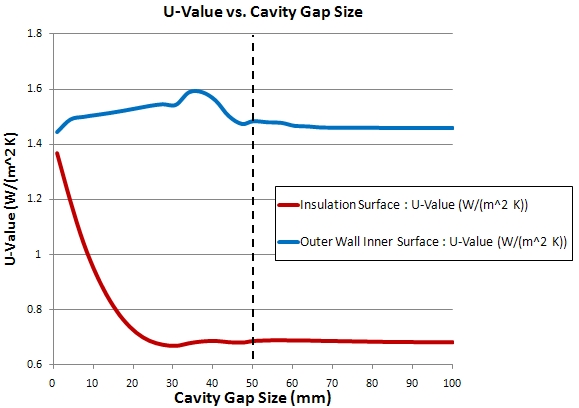

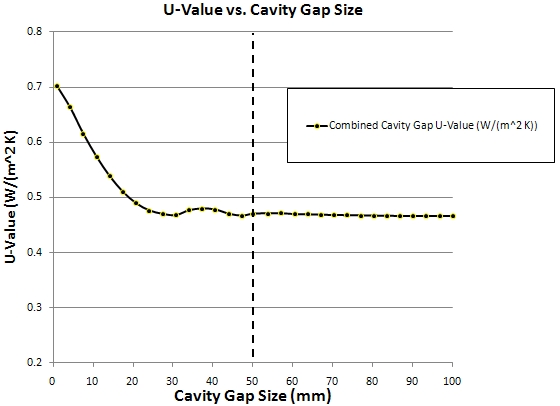

U-Value is a measure of the ease by which heat can pass through something. The required maximum overall U-value of 0.3 is for the entire wall construction, from room temperature to outside temperature. Local U-Values can be determined at any point (rather vertical plane) within the wall. A U-Value exists for the left side of the cavity air gap, where the heat passes from the insulation to the air. Another U-Value exists for the inner surface of the outer wall, where the heat passes from the air gap to the outer wall. Plotting the variation in these two U-Values with gap size provides further insights…

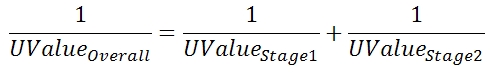

Heat passes very easily from the insulation to the air when the gap size is reduced. For the inner surface of the outer wall the opposite is true, a little. If you have say two U-Values indicating the ease by which heat passes sequentially through two stages you can combine these into a single U-Value that represents the overall U-Value for the cavity. Time for an equation and for that I’m sorry.

Using the above to combine the U-Values for two sides of the cavity we get:

So, by isolating the effects of the cavity air gap on the overall U-Value we can at least observe that you can decrease the gap size to about 30mm without an adverse effect on increasing U-Value and having gap sizes up to 100mm (and extrapolated well beyond that) will have no subsequent beneficial or detrimental effects.

Hey, hold on Robin, you could have figured that out from your first room temperature vs. gap size plot! True young padawan but at least this way I’ve introduced how FloVENT can be used to drill down to specific areas of a model to start to find out why the U-Value changes as it does. What is special about the heat transfer from the insulation to the air? Why is that much more sensitive to the gap size? Why is it that the gap size has no effect when > 50mm? All good questions, to be answered next time.

17th Febrary 2010, Nottingham