Top 10 FloTHERM V10 Features – #5: FloSCRIPT

Flo. As far as prefixes go, I don’t know of another company that uses one so consistently for product branding, well apart from Apple. ‘Flo’ comes from ‘Flow’ and was part of the naming of Flomerics (Flow-Numerics), the company that first developed FloTHERM (flow-thermal) and FloVENT (flow-ventilation). FloMOTION was a favourite branding (animated post-processing module). Other completely unrelated Flos include Flo Rida, Flo Jo and Auntie Flo. We still use this prefix (though try to steer clear of too much conFlosion) and when it came to naming a new automation scripting technology we developed for FloTHERM V10, the name was obvious; FloSCRIPT.

Scripting allows for instructions to be stored/recorded/replayed that would otherwise have to have been done manually in the GUI. As such, scripting can do no more than would be possible manually. What it can do though is to automate such tasks. Automation saves time and can be used to impose quality and consistency on the simulation process.

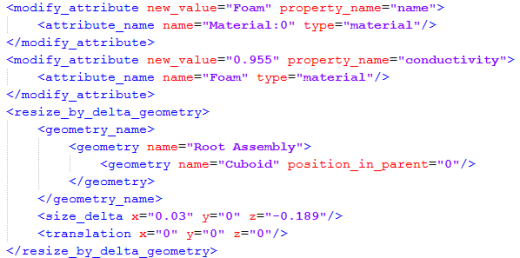

Each FloTHERM session is logged to a FloSCRIPT file, the last 5 session scripts are retained (in the \flosuite_v10\flotherm\WinXP\bin\LogFiles directory). FloSCRIPT is XML based, with each operation performed in the new Project Manager / Drawing Board window being logged.

Each FloTHERM session is logged to a FloSCRIPT file, the last 5 session scripts are retained (in the \flosuite_v10\flotherm\WinXP\bin\LogFiles directory). FloSCRIPT is XML based, with each operation performed in the new Project Manager / Drawing Board window being logged.

An obvious application for this technology is when it comes to communicating with customer support. Gone are the days where a user would have to remember and recount the steps they went through when helping a support engineer replicate the steps leading to the issue being reported. Now it’s simply a case of sending the FloSCRIPT file whereupon the support engineer can replay it (using [Project/Run FloSCRIPT…]) to repeat the steps directly.

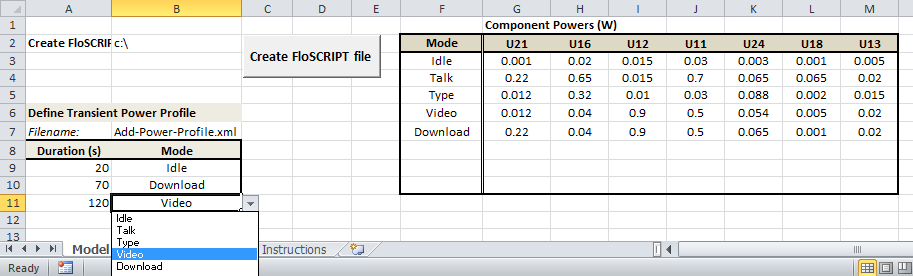

Although FloTHERM has a wealth of functions and features, often these operate at a lower level than the input might be defined at. Sure, it’s possible to define a transient variation of power dissipation as a function of time, using inputs such as start time, end time, power multiplier, attachments of such transient attributes to those objects that should vary their power dissipation in time (e.g. via RefDes of all actives). However this is somewhat removed and cumbersome when compared to how the input might be considered by the user, e.g. ‘the device should be in idle mode for 20 seconds, receiving data for 70 seconds then play video for 120 seconds’ where a table of power dissipations reflects these differing modes of operation. FloSCRIPT can be bought to bear on this, enabling the input to be phrased intuitively, and for the FloSCRIPT to do the low level implementation of this input.

A FloSCRIPT generating spreadsheet example is installed to \flosuite_v10\flotherm\examples\FloSCRIPT. It enables capture of the simulation intent directly. A lookup table indicates the various power dissipation levels, per RefDes, for each mode of operation of the model. The transient power profile itself is captured via a Duration vs. Mode table. The ‘Create FloSCRIPT file’ button then runs Visual Basic scripting to convert the input into a series of commands that can be applied to a loaded model, again via [Project/Run FloSCRIPT…].

Running the FloSCRIPT on a loaded model will, in one click:

- set the model to transient

- define the overall transient solution time

- define appropriate time patches with efficient time step distributions

- create transient attributes that specify the power dissipation vs. time

- attach the transient attributes to the relevant thermal attributes (using RefDes as the keying)

If you have to demonstrate the thermal compliance of your model in a number of differing customer environments then such an automation may save you a massive amount of time.

FloSCRIPT together with FloXML provide a wealth of other automation opportunities. Byron Blackmore gave an excellent overview of both automation technologies in this webinar, well worth checking out.

If I had an independent report to prove it I’d say that, unlike any other comparable CAE tools, it’s the inherent simplicity and subsequent robustness of FloTHERM’s underlying technology that enables FloTHERM to be automated to this extent and that, although other tools purport to have similar technologies, attempting to automate them is compromised due the amount of manual intervention required when the automation fails. I don’t though, so I won’t.

10th June 2014, Ross-on-Wye.