Experiment vs. Simulation, Part 3: JESD51-14

The JESD51-14 standard was published in November 2010, prepared by the JEDEC JC-15 Committee on Thermal Characterization. It outlines a new process to measure what is the most common IC package thermal metric, Theta_jc. This is the thermal resistance between the die and the package case face. More specifically the face of the package that is to be cooled by an external heatsinking method. Theta_jc wasn’t a new metric that required a new method to be proposed to measure it so what was the motivation for this standard? You can learn more about something when considering -why- that thing was done beyond -what- the thing actually is.

A thermal resistance has units K/W (or DegC/W, take your pick). It is a formed by temperature difference divided by a power dissipation. The power dissipation being the amount of power consumed by the package that is dissipated as heat (in most cases, all of it). The temperature difference is difference between the junction temperature and the temperature of the case face. The classic method to measure Theta_jc is to record the consumed power, use an electrical test method to measure the temperature of the die and a thermocouple to measure the temperature at the case face. It’s this latter part where most of the problems lie.

The package case face is totally covered by the heatsink. To measure the case face temperature using a thermocouple you drill a hole through the heatsink, insert the thermocouple through that and try to ensure the thermocouple bead just records the package face temperature and is not affected by the surrounding heatsink. A method that is susceptible to variations when repeated by different engineers/companies. Even more so with small packages that have a case face area similar to the size of the thermocouple bead. Also there is the issue of what temperature to measure when the temperature variation across the case face is not uniform (as can be the case, even with high HTC heatsinks and especially for packages with large die to case size ratios). The maximum temperature sure, but how do you know where that is exactly?

The primary use of Theta_jc is as a comparison metric to enable end users to judge the relative thermal performance of different packages, often from different suppliers, to determine which is thermally more attractive (i.e. the one with the lower Theta_jc, or a more cost effective Theta_jc). To enable decisions based on such comparisons to be made successfully one would need to ensure that all Theta_jc values have the same, and small, measurement error. And yes, even measurements have errors, as do simulations, in fact nothing is ‘accurate’, the only thing to strive for is usefulness. Sorry, best to stop there before things get a bit too philosophical. Thermocouple approaches introduce too many large and variable errors. It was this that fact that drove the need for a new standard for the measurement of this prince of thermal metrics.

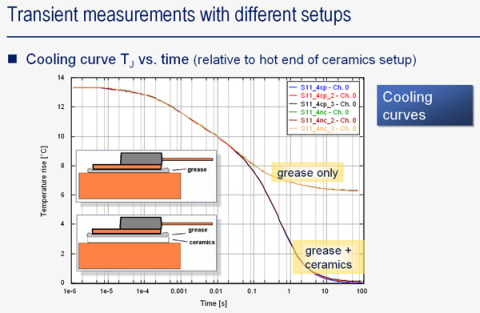

JESD51-14 details the ‘Transient Dual Interface Method’ (TDIM) testing approach. I won’t attempt to a better job at describing the method than Andras Poppe has already done in a previous blog. I will however shamelessly copy his picture that gives a graphical overview. It’s a neat concept. Change the condition over the whole case face between two transient (power down) measurements and note the dT in time at which the Tj vs. t curves deviate.

JESD51-14 details the ‘Transient Dual Interface Method’ (TDIM) testing approach. I won’t attempt to a better job at describing the method than Andras Poppe has already done in a previous blog. I will however shamelessly copy his picture that gives a graphical overview. It’s a neat concept. Change the condition over the whole case face between two transient (power down) measurements and note the dT in time at which the Tj vs. t curves deviate.

I have come across many questions and been part of a few deep discussions about the comparison between thermocouple and TDIM measured Theta_jc values. Are they comparable? If so, how? Most of the time such discussions turn back to the basic fact that JESD51-14 details a repeatable approach to determine a thermal metric that can be used during component selection phase of the design process. Safe ground.

However these discussions start up again when people start using Theta_jc for prediction / simulation purposes.

“But it’s only meant to be a metric!”

—“I know but it’s the only bit of thermal data I can find and I need to determine how hot this package will get in my product”

“Can’t you get a detailed FloTHERM model?”

—“Tried that, the supplier wouldn’t provide it, too much proprietary info would be contained within it”

“What about entering into an NDA with them to cover the supply of a detailed model?”

—“What, by Monday!?”

It’s the lack of thermal models that is driving thermal engineers to use whatever they can for simulation purposes. Theta_jc included. Next time I’ll cover some pros and cons about doing this.

22nd February 2012, Ross-on-Wye