3 takeaways from the SEU16 3D printing expert panel

Suspension mounting 3D printed by Craig Hall

Suspension mounting 3D printed by Craig Hall

We had an excellent group of Solid Edge users and industry experts to discuss 3D printing and additive manufacturing on our expert panel at SEU16 last month. The panel was chaired by industry analyst Monica Schnitger – you can access a video of the panel here – but the audio is a bit hard to follow in places so here is a summary of the panel discussion:

3 key takeaways for me were:

- Solid Edge users are successfully using their own 3D printers for prototyping and tooling today.

- Review the components you manufacture and use a service bureau to print selected parts in a variety of materials before investing heavily in your own hardware.

- Engineering expertise is still required to take full advantage of fast developing 3D printing and additive manufacturing techniques.

- Solid Edge users are using their own 3D printers today for prototyping and tooling

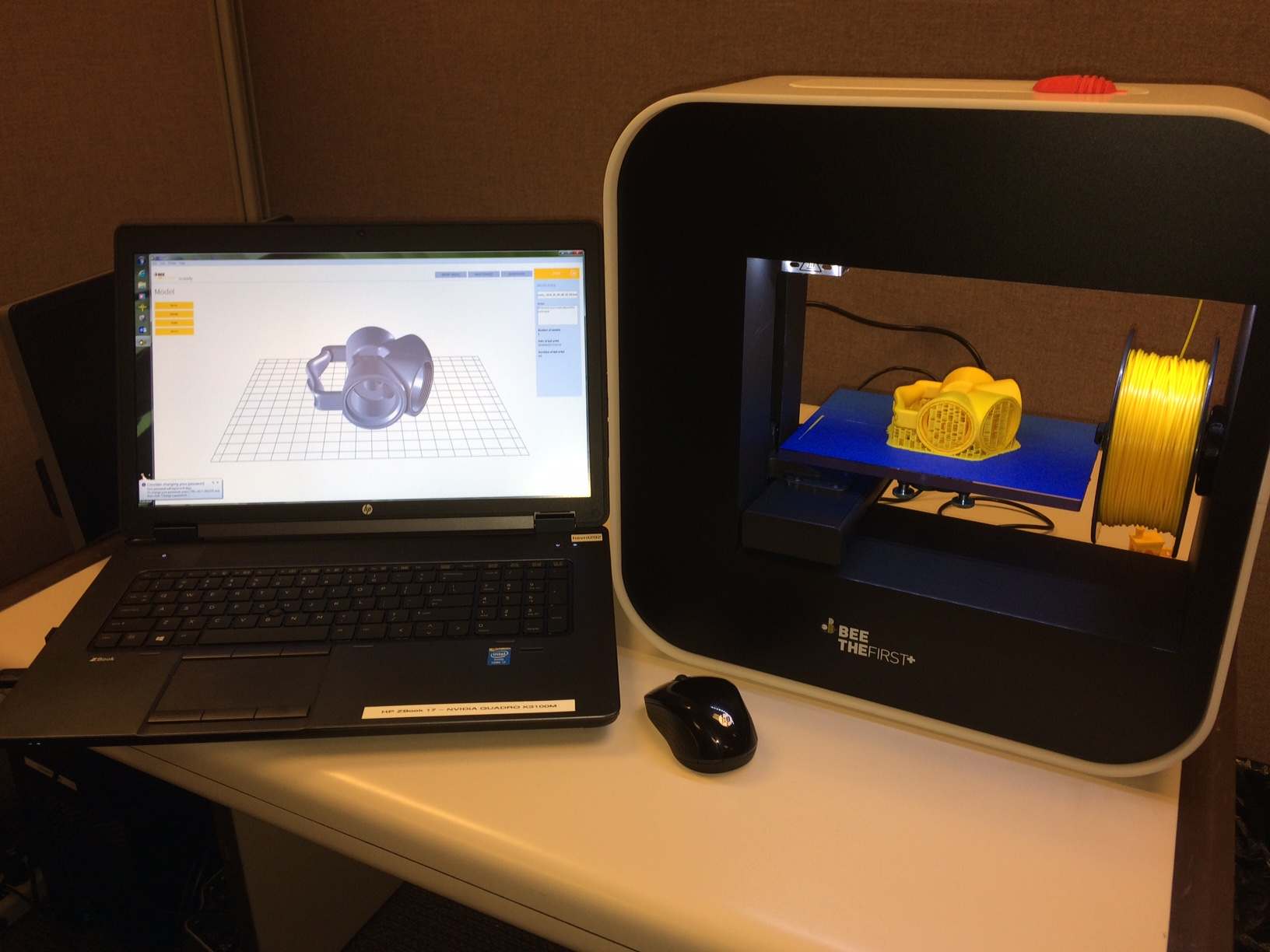

We had two Solid Edge customers on the panel – Craig Hall from Craig Hall Designs and Richard Willoughby from Ditch Witch. Craig showed us a suspension mount prototype that he had printed on his own 3D printer, the final part will be machined from steel. Creating the 3D prototype had enabled him to discuss and agree the design with prospective customers, work with his machinist to decide how best to manufacture the final part, and actually attach the suspension rods to the prototype part to check on clearances and tolerances. Richard Willoughby from Ditch Witch described a rock saw that they manufacture that has complex tooling requirements. Using their 3D printer they were able to create the welding bit holders that they use during the fabrication of the saw in a fraction of the time comparted to their previous manufacturing method. John Reilly from Mark Forged, a provider of 3D printers for composite parts, recommended that smaller organizations can easily start out with a desktop type printer and make rapid progress along the learning curve. That is one of the ways that we in the Solid Edge marketing team have been educating ourselves about this new technology area.

Desktop 3D printers can be used to create your first 3D printed prototype parts

Desktop 3D printers can be used to create your first 3D printed prototype parts

2. Review the components you manufacture and use a service bureau to print selected parts in avariety of materials before investing heavily in your own hardware.

Stephan Kühr from the 3D printing service provider 3YOURMIND recommended that manufacturers examine their inventory of parts, and then choose a small sample of those parts that could be suitable for additive printing. Stephan mentioned looking at size, complexity to manufacture using traditional methods, desired material type and opportunity cost if you don’t have the part in stock as some criteria for the selection process) and have them printed in a few different materials by a 3D printing service bureau. This will enable you to see for yourself characteristics like price, surface finish and strength. You can find out more about the 3YOURMIND plugin for Solid Edge here.

Ed Israel from Plural Additive Manufacturing proposed something similar – actually walking through your warehouse, picking out parts and asking yourself what the current manufacturing process is, could the part be made from plastic instead of metal and is it a good candidate for 3D printing? Ed recommends you pick a few of these parts and get them printed. He also gave an example of an aircraft seat component for the Airbus A320 that they were able to manufacture that was stronger and had 45% less weight than the existing component.

- Engineering expertise is still required to take full advantage of fast developing 3D printing and additive manufacturing techniques

The final takeaway I got from the panel is that there still a huge place for engineering excellence in this area, working hard to develop your knowledge and by implementing good engineering practices.

John Reilly mentioned how they had application engineers who were skilled in component selection and design for additive manufacturing, and how they are publishing blog posts to help their customers improve their own skills.

Philipp Tietjen from Siemens PLM Software talked about how introducing these new manufacturing processes gives your more scope to optimize your designs, for example by utilizing more organic shapes that would be hard to manufacture using traditional engineering processes. And by incorporating honeycomb structures into certain areas of the component to reduce weight and material usage while maintaining strength. Philip also mentioned how Siemens is working closely with the 3D Printer suppliers like Mark Forged and Plural Additive Manufacturing components to determine how components can be best oriented for 3D printing, and how the printing process parameters influence the quality of the final product.

We are always interested to hear more from our Solid Edge users who are using 3D printing and additive manufacturing techniques!

3D Printing expert panel at SEU16

3D Printing expert panel at SEU16

Comments