Why Should You Use CFD?

Do engineering decisions seem to be getting harder?

If you feel that way, you’re not alone. Tech-Clarity research consistently finds that products are becoming more and more complex. With that increasing complexity, engineers must consider more factors when making design decisions. There are more components, more configurations, more electronics, more materials, and more regulations, just to name a few. It’s a lot to think about, and it’s not easy.

Engineering Decisions Are Critical to Product Success

Engineers are rockstars for their companies. It’s the work they do that makes products amazing, innovative, and cool. Without talented engineers, companies would lose much of their power to become competitive.

Our research at Tech-Clarity finds that the essential product qualities that will make products competitive over the next five years are:

- Product quality

- Reliability

- Cost

These are precisely the qualities that are impacted by engineering decisions. Consequently, if engineers aren’t empowered to make the right decisions, products will be less successful in the market. Unfortunately, with growing product complexity, the right decision is becoming more difficult. In fact, recent Tech-Clarity research finds that engineers lack confidence in their decisions 28 percent of the time. That’s a lot of opportunity for improvement.

The Value of Simulation

To help improve that confidence, simulation can be one of the best tools for an engineer to get better insight. With simulation, engineers can evaluate multiple options to better inform their decisions.

In a recent webinar about the importance of CFD, I made a comparison to a Simpsons episode, Itchy & Scratchy Land. In this episode, Homer decides reading a map will take too much time, so he throws it out, and instead tries to get to Itchy & Scratchy Land by relying on his gut instinct. He makes it, but the result isn’t pretty. Given how sophisticated today’s products are, making design decisions without the aid of simulation is much like trying to get somewhere without a map. You’ll get there, but you’ll probably run into some problems.

Why CFD?

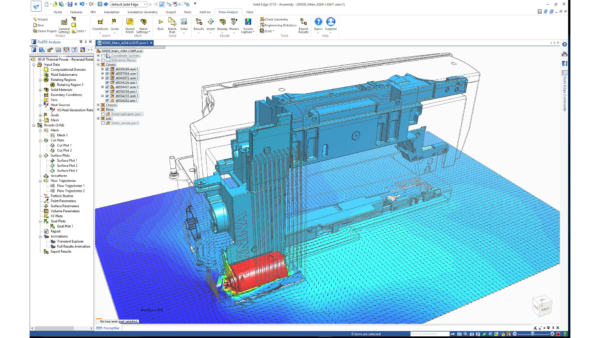

With the increase in product complexity, there is also an increase in the number of physics involved. This means that beyond just structural simulation, you may also want to consider some additional physics, which requires other analyses. One that is growing in importance is CFD, or Computational Fluid Dynamics.

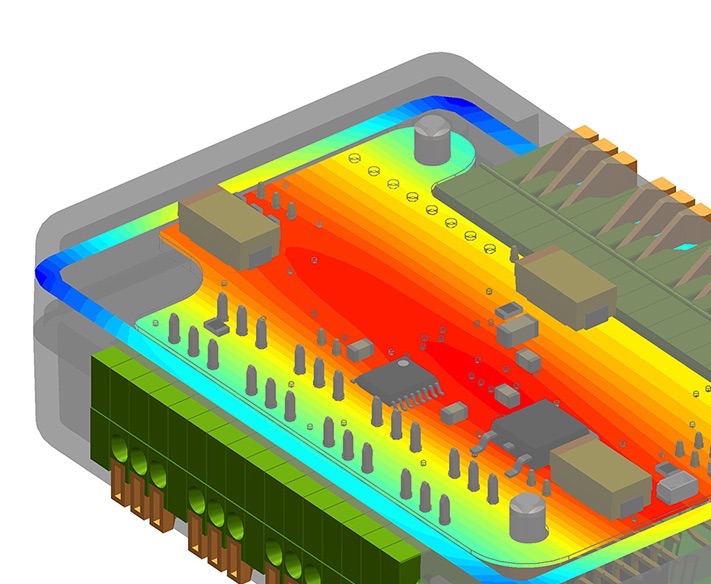

CFD analyzes the flow and interactions of fluids, so it includes both liquids and gases, and can analyze natural phenomenon such as airflow. With the increasing amount of electronics in products, CFD has become especially important. It can help you avoid some of the most common problems during product development that lead to failure.

Practical Uses for CFD

With CFD, you can easily answer important questions, such as:

- Will this product overheat?

- Can I avoid a heat sink?

- Which fan should I use?

- Will the product be too loud?

You can then take necessary actions, such as:

- Adjust the geometry for better cooling or flow

- Use a less expensive fan or pump that will still meet performance requirements

- Improve the aerodynamics of your design

- Identify noise sources and work to minimize them

Armed with these results, you can:

- Lower energy and fuel costs for your customers

- Ensure electronics don’t fail prematurely

- Ensure performance requirements are met

- Lower product cost by avoiding over-engineering

Often, decisions like this have an impact on the rest of the design, especially if you make fundamental changes to the geometry. Unfortunately, if you wait until the design is complete to do this type of analysis, it will be much harder to explore options. Late in the design cycle, too much of the design will be too far along. Major changes will be too disruptive and likely lead to errors. If you can get insights like this early on when you are first making decisions, you’ll end up with a much better design.

Learn More

To learn more about CFD, how it can help, what to look for in a solution, and a demonstration of the Solid Edge solution, take a moment to watch the on-demand webinar, Are you using CFD during design?

The following video provides a brief introduction to the webinar:

Comments