FloEFD for Solid Edge introduced at SEU16

A new computational fluid dynamics (CFD) solution for Solid Edge was announced today at SEU16. FloEFD for Solid Edge from Mentor Graphics is embedded within Solid Edge and provides comprehensive but easy-to-use capabilities to analyze many different fluid flow problems; this solution helps users optimize their designs at an earlier stage in the product development process.

There have been several CFD solutions available to Solid Edge users but these typically require the users to export their geometry from Solid Edge to a separate application to perform the analysis. This is itself a tedious process but also makes it hard to incorporate changes in the design into the analysis.

Mentor Graphics describes FloEFD for Solid Edge as the only frontloading computational fluid dynamics (CFD) analysis tool that is fully embedded in Solid Edge. Frontloading CFD refers to the practice of moving CFD simulation early into the design process where it can help design engineers examine trends and eliminate less desirable design options. FloEFD can be used to analyze heat transfer and aerodynamic issues across many industries (process plant, industrial equipment, HVAC and refrigeration, consumer products, automotive, aerospace and electronics for example) and covers many analysis types (stationary or transient flows, heat transfer, forced and natural convection, radiation heat transfer, rotation, fans and heat sinks, thermal and electrical contact resistance for example).

Some of the many analysis types supported by FloEFD in the process and industrial equipment industry

Some of the many analysis types supported by FloEFD in the process and industrial equipment industry

I spoke with Richard Ozaki and Chris Watson from Mentor Graphics at SEU16 and two key differentiators that they pointed out for FloEFD for Solid Edge are that firstly it is embedded within the Solid Edge environment for faster analysis setup and easier handling of design changes, and secondly the advanced meshing techniques they use are much faster than other solutions and require minimal simplification of your CAD models.

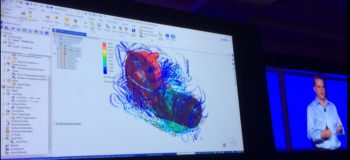

Chris Watson from Mentor Graphics introducing FloEFD for Solid Edge at SEU16

Chris Watson from Mentor Graphics introducing FloEFD for Solid Edge at SEU16

You can check out more details on our FloEFD for Solid Edge web page.

Comments