How Solid Edge ST10 will impact digitalization at Kimball

Ricardo Espinosa from furniture manufacturer Kimball International participated in our beta program for Solid Edge ST10 and presented his perspective at the launch in Indianapolis. This short video interview captures some of Ricardo’s thoughts on Solid Edge ST10. Kimball International has been using Solid Edge and Teamcenter since 2003 and have around 60 licenses of Solid Edge and 300 of Teamcenter. They have seven manufacturing plants in Indiana and are growing fast, you can see their products in many hotels and offices. Using Solid Edge and Teamcenter has been critical for Kimball’s digitilazation strategy, where they use 3D digital models throughout the product lifecycle,enabling them to shorten the time for introducing new products to the market.

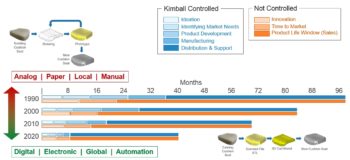

Kimball’s digitalization strategy is helping them to shorten product development cycle time and bring new products to market faster

Kimball’s digitalization strategy is helping them to shorten product development cycle time and bring new products to market faster

One of the key areas that Ricardo comments on is how ST10 will help them work better with the .STL files that they work with. They use library parts (lamps, cushions, arm rests) in .STL format when designing furniture and when creating high quality renderings of their furniture in an office or hotel environment, and thay also scan some of the parts that they purchase when no CAD model is available. Ricardo believes that ST10 will help them integrate these mesh based models into their product development workflow more easily. And within the core design capabilities of ST10 they particularly like the new “clone” capability where they can easily place a specific part such as a dowel in the many different places it is used in an assembly – Ricardo believes this will save significant time in the design process.

Kimball uses Teamcenter extensively, but they also see an opportunity to use the built-in data management capabilities that have been enhanced in ST10 at one of their smaller sites. The fact that the user interface is similar between built-in data management and Teamcenter will help their designers use either system with minimal training. You can read more about Kimball’s use of Teamcenter here.

Comments