“Frontloading” Simulation Results in Optimized Products

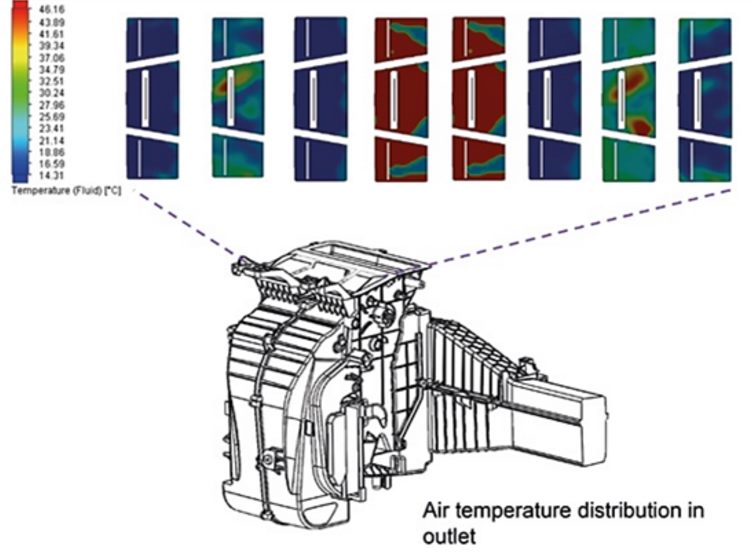

Air flow analysis in an automotive heater + air conditioning unit

Air flow analysis in an automotive heater + air conditioning unit

Many engineering organizations are frontloading simulation, including Computational Fluid Dynamics (CFD), by moving it to the beginning of the design cycle. By making early fluid flow and heat transfer simulation the responsibility of designers rather than specialists, manufacturers can slash the design cycle, lower their engineering costs, and achieve a superior return on investment. Engineers design and analyze early in the design process to discover potential design flaws, then redesign, meaning they can iterate quickly to get to the optimal product design.

Specialized analysts can still step in later in the project, but they will be working with parts that need fewer and smaller design changes than they would without the frontloading process. The designs also meet specifications without being overdesigned. The key to frontloading is the use of fully integrated CAD and analysis software. These integrated systems allow engineers to move quickly and seamlessly between product design in 3D CAD, performance analysis, and redesign.

The recent integration of FloEFD from Mentor Graphics with the Solid Edge CAD system from Siemens PLM brings the ideal solution for frontloading CFD into a modern, easy-to-use CAD system. The FloEFD tool helps design engineers conduct CFD analysis early in the design process. Now embedded in Solid Edge, FloEFD offers intelligent technology that helps engineers set up and analyze problems quickly, it helps reduce overall time to a solution by as much as 65 to 75 percent compared to traditional methods and products.

Riding in Comfort

Take, for example, the Pan Asia Technical Automotive Center in Shanghai. The center engineers Shanghai General Motors vehicles as well as acting as one of six global GM technical development and design centers. With the huge increase in car ownership in China, drivers are seeking high levels of comfort, including air-conditioning that maintains a uniform temperature throughout the passenger cabin.

Ensuring uniform temperature is a matter of engineering and airflow. Automated gates act as control valves inside the air conditioning unit and determine the hot and cold airflow “mixing ratio.” The “hedge angle” and “area ratio” of the cold and hot airflow channels have an important influence on the temperature and uniformity of the final mixed airflow that is delivered to the cabin.

FloEFD was used to optimize performance of this air handling unit early in the design processEngineers at the technical center used FloEFD early in the design process to examine a range of hedge angles for hot and cold airflow channels and determine how best to design the air conditioning unit, according to Lu Ping, an engineer at the center. “The software showed ways to improve design performance to achieve an optimized design and at the same time reduced our overall cost of development,” Ping says. Engineers found a hedge angle of 120 degrees and an area ratio of 39 percent respectively to be optimal for maintaining uniform cabin temperature, he says. They subsequently engineered the unit to reflect this optimized hedge angle and area ratio.

FloEFD was used to optimize performance of this air handling unit early in the design processEngineers at the technical center used FloEFD early in the design process to examine a range of hedge angles for hot and cold airflow channels and determine how best to design the air conditioning unit, according to Lu Ping, an engineer at the center. “The software showed ways to improve design performance to achieve an optimized design and at the same time reduced our overall cost of development,” Ping says. Engineers found a hedge angle of 120 degrees and an area ratio of 39 percent respectively to be optimal for maintaining uniform cabin temperature, he says. They subsequently engineered the unit to reflect this optimized hedge angle and area ratio.

“We adopted FloEFD for this study because of its ease of use in meshing when compared to the tetrahedral or prismatic meshing approaches in traditional CFD codes,” Ping says. “We found that FloEFD gives more accurate and more efficient CFD simulation results. Since it works within the mechanical CAD environment, it is a highly engineered universal fluid flow and heat transfer analysis software.”

You can find more details of this case study here. And just a note that this is the third in a series of posts on fluid flow and heat transfer analysis. The first focuses on industry challenges in this area, and the second discusses FloEFD for Solid Edge.