Solid Edge 2020 launched at Realize Live

Democratization of software solutions for product development was a key theme of the Solid Edge 2020 launch at Realize Live today. With the Solid Edge portfolio, leading technology solutions developed and acquired by Siemens are being made available as integrated, packaged solutions that meet the need of start ups, small and medium size manufacturers. Realize Live 2019 includes a comprehensive agenda of presentations, hands-on classes and round tables for Solid Edge users, and Dan Staples and Jon Sutcliffe kicked off the Solid Edge focused sessions with a fast paced presentation to customers, journalists and industry analysts. Here are a few of the highlights of Solid Edge 2020.

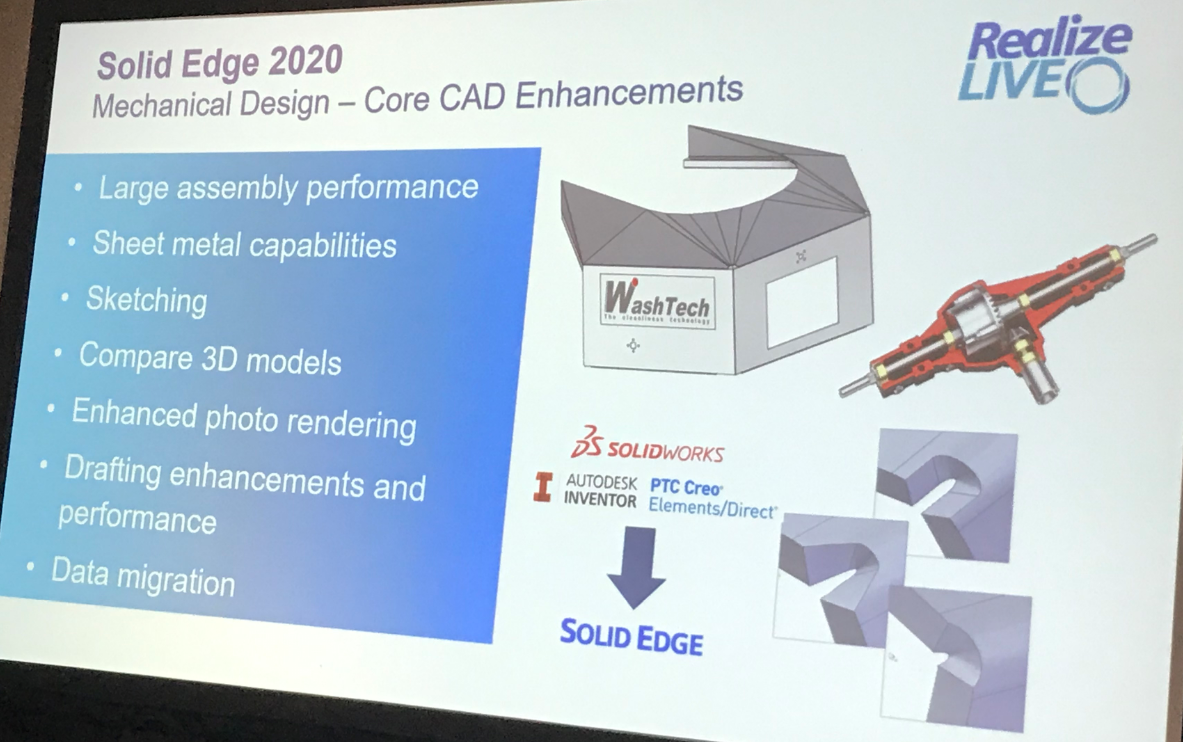

Washtec is an example of a smaller manufacturing company that is taking advantage of the Solid Edge portfolio is Washtec. They have just 16 employees and design and manufacture machines for cleaning industrial components. They have been using Solid Edge since their foundation in 2015, and have recently added modules for electrical wiring design, technical publications and fluid flow analysis and are experiencing significant improvements in their product development process including 60% faster design of wiring circuits, a 20% faster assembly process, and 57% lower product testing costs.

Enhancements to core CAD capabilities include a new 3D compare capability, and new sheetmetal modeling capabilities including bend bulge relief and creating bend definitions for transitioning geometry. Improvements are also made in performance for handling large assemblies and creating complex drawings, and new photorealistic image creation capabilities.

Augmented Reality is one of the new capabilites being added to Solid Edge 2020, enabling digital designs to be evaluated in a real world environment. The process starts in the Solid Edge Portal, a free application for collaborating around design data in multiple CAD formats. Here a QR code is generated from a part or assembly model that has been stored in the Portal. The Solid Edge Viewer is then used to view the model in a real environment. For example, an industrial machine can be visualized in its location on the actual factory floor, or a domestic appliance can be visualized in a real kitchen environment.

Model Based Definition (MBD) is another area of development and offers clearer communication of design intent for manufacturing using 3D drawings. Solid Edge has had capabilities in this area for some time, for example with 3D driving dimensions being placed on 3D synchronous models. New capabilities include the ability to add annotations to 3D models and the ability to create 3D cross sections, also the abilty to create 3D PDF documents with multiple, annotated 3D model views and interactive parts lists.

Reverse Engineering is used to create 3D Solid Edge models from physical components. New capabilities include the ability to remesh models to reduce their file size and make them easier to work with. For example, a reduction in files size from 80MB to 10MB can be achieved. This is one example of leveraging technology from a Siemens acquisition with Siemens acquiring CD-adapco in 2016. Other enhancements include the ability to create sketches based on cross sections of mesh data and the ability to place origins in the optimum position and orientation to facilitate positioning of the model in an assembly.

In the area of additive manufacturing Solid Edge 202 includes new Design for Additive Manufacturing (DfAM) capabilities including the ability to delete voids and to ensure a minimum wall thickness, and the ability to create physical threads and to identify overhangs. A new manufacturing application is Solid Edge 2D Nesting. This enables diverse 2D shapes to be nested in the most efficient way enabling significant savings in material costs for sheet metal components. One distinct feature is the ability to nest a set of shapes across a set of sheets with different sizes, enabling efficent use of available materials.

For those designing electromechanical products new capabilities in Solid Edge Wiring Design include the ability to create ladder diagrams for control panels and the ability to flatten 3D harnesses to create accurate 2D schematics of the required wiring. Solid Edge PCB Design is also introduced with both PCB schematic and layout design modules, and the ability to create 3D models of PCBs for accurate packaging in a mechanical assembly.

Solid Edge Simulation has been significantly enhanced with new dynamic motion analysis. Forces resulting from motion can be calculated and made available for stress analysis. Velocity, force and stress can be plotted for the full range of motion. Transient heat transfer situations can also be analyzed.

The above is just a selection of some of the key new capabilities in Solid Edge 2020. You can find out more on our website or read reviews from Cimdata and 3D CAD World.