Simulation, Analysis and Decisions

While we’re on the topic of abstraction from my previous post, let’s carry it further to simulation. About 15 years ago or so if I’m remembering correctly, we had a movement called the “Up Front” movement. It was primarily CAD vendors moving into the FEA space, trying to sell a little more software The overall thrust was to get design engineers to use some FEA tools. The argument in favor was that getting some analysis results “up front” in the design phase meant you would have fewer changes later in the project when changes become much more expensive in both time and money. The argument against was that design engineers don’t always have the skills of seasoned analysts. It’s the old GIGO technophobe argument (garbage in garbage out).

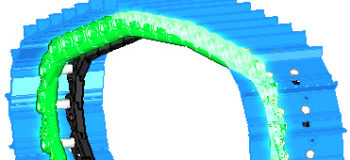

FEA (finite element analysis) is another level of abstraction. But it’s not just a visual analogy like it was for Ug and Um in the previous post. FEA obviously has to go through a couple layers of mathematical abstractions where the math is used to approximate the physical world, and then the user has to understand two things: setting up boundary conditions to model reality and then interpreting the results. Of course the results are meaningless if the setup is incorrect.

In the last decade, you hear the word “simulation” more frequently than “FEA” or “analysis”, probably because these latter words bring with them a more intimidating sense of the need for specialists skills. Lowering the bar for entry into this world brings with it opportunity for a new group of people, with some of the responsibility moving from the analyst level with its need for special training and/or experience to the engineer or designer with mainly mechanical design and design documentation skills. Of course the field mechanical engineering represents a broad range of skills that includes this entire range

We talked about visualization as an abstraction that even non-technical people can learn to grasp, but as the discussion progresses to FEA, the new skill takes not just an understanding of the underlying physics, but also the quirks of the mathematics involved. Intuition is often helpful, but can also lead to incorrect assumptions if you rely on it too frequently without understanding and verification.

While I don’t believe the days of the dedicated structural or dynamic analyst are over, you may not see as many of them as you might have 10 years ago. Faster computers just mean the analysts are taking on more detailed work, but at least some of the load they used to carry is being done up front.

The debate 15 years ago was intense as to whether design engineers should be doing analysis. To some extent it still continues, because design engineers have to make sure that they have at least a passing familiarity with the concepts used in various types of analysis. But today engineering managers understand that the real question is how to get the project done on time rather than who does what work.

Getting at least a ball-park view of whether or not you’re going to need aluminum or plastic can be essential early in the design phase because injection mold tooling and casting tooling are both long-lead items. It might sound crazy to get started on both sets of tooling even though only one will be needed just so you don’t get caught with no tooling when you are so near production can be expensive – but then so is being 3 months late because tooling is incomplete.

So in real projects, it turns out that the analyst might be called much earlier on than they used to be to help determine materials or manufacturing methods, and then called on again after the detailed design is done to act as a prototype check. Design engineers are still doing simulation for geometry or assembly method type decisions, because you can easily get paralyzed by analysis.

In all this, the software we rely on is helping us make better decisions by presenting us with data. The software is not making the decisions for us. We have also used these tools to help us establish better workflows that in turn help us make even better decisions at the appropriate time. We need both the high end and the mid-range tools to help the right people with the right decisions.

Comments