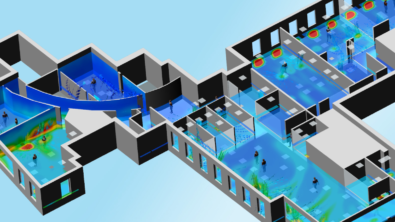

Enhancing designs with flow simulation

Predicting product performance is no easy task – especially when that performance involves fluid dynamics. Traditionally, the work has been difficult to the point that simulation analysis specialists were required to perform fluid and thermodynamic simulations outside of the design phase, driving up development time and costs.

Fortunately, things are changing. Modern simulation tools are empowering engineers to analyze fluid and thermal behavior. They can perform these analyses earlier in the design phase, allowing them to catch and correct errors before the process has progressed too far. In addition to saving valuable design and development time, these simulation tools enable engineers to assess various design concepts and make more informed decisions.

Modern thermal and fluid dynamic simulations enable engineers to create better, higher quality products quickly – and with greater room for innovation. And best of all, these automated tools are easily accessible, allowing engineers to:

- Make more informed design improvements

- Save time during the development process

- Cut costs significantly

- Integrate simulations with computer-aided design (CAD) applications

We recently published an eBook that explores the tangible benefits of flow simulation, and how moving simulation earlier in the design process can be the key to unlocking these benefits.

Front-loading flow analysis improves product performance

By front-loading fluid and thermodynamic simulations in the earliest stages of the product development process, you identify product issues earlier, making them much easier to fix. Learn how simulation-guided design decisions give you more flexibility to experiment with numerous design options, predict the effects of different design concepts to find the optimal choice, and result in higher-performance products.

CFD integration with CAD applications

Integration between simulation and CAD applications is critical for simulation-driven design. CAD applications generate 3D models, drawings and other digital representations of physical parts. Any simulation must functionally represent these designs, and any improvements that originate within a simulation should alter the original mechanical design. Download the eBook to learn more about the three meaningful ways that the best fluid and thermodynamic simulation solutions connect to CAD tools.

Comments