New research shows impact of good data management practices

Word cloud from Tech-Clarity’s new research on data management

Word cloud from Tech-Clarity’s new research on data management

Companies who boast world-class performance for product development rely on effective data management tools, but implementing comprehenisive data management is a still a business challenge for many engineering and manufacturing firms. That’s the word from a recent report from independent research firm Tech-Clarity. The ability to track and store information is becoming increasingly important as products continue to become more complex according to this new research. The report gathers 300 responses about best practices for data management. Responses came from designers, engineering managers and engineering directors. New research from Tech-Clarity on data management

New research from Tech-Clarity on data management

The report’s most importing finding is disclosed in its name: “Design Data Management Maturity Improves Productivity.” It looks at how companies deal with tracking and managing ever-increasing product complexity, managing all the associated technical data that is needed for product development, and the associated engineering and manufacturing workflows.

The results make a strong case for data management and product lifecycle management systems. These systems act as a single source of product data that can be accessed by design and manufacturing teams. To take the analogy of a physical library, when books aren’t stored according to a system, users have trouble finding what they need. The same is true of product data. Employees at engineering and manufacturing firms have trouble accessing the product data they need to do their jobs when they don’t have access to a system that manages that information. Siemens makes two tools, both of which can be integrated with the company’s Solid Edge CAD system, to resolve this issue. Smaller companies can call upon the data management system already built into the CAD software, while midsize and larger companies usually turn to Teamcenter, the Siemen’s PLM tool integrated with Solid Edge.

Data management is an issue for companies no matter their size. A previous Tech-Clarity report, “Best Practices in Managing Design Data,” found that product complexity is a larger driver of data management issues than company size.

Time spent on non added value activities

Companies are finding the capability to track and store information is essential as their products become more intricately designed. Products include more features than ever before—and often incorporate electrical components and software systems in their designs. The survey found that employees at companies without adequate systems spend, on average, more than 15 percent of their time on data management tasks that don’t add value to the product or the company. Nearly one-third of companies surveyed spend more than 25 percent of their time on these non-value-added activities, according to the report.

Proportion of respondents reporting % time spent on non value added data management tasks

Proportion of respondents reporting % time spent on non value added data management tasks

In addition, companies surveyed also reported search-related challenges, which also contribute to productivity losses, as does spending time on repetitive data management tasks. Without best practices in design data management, firms already struggling with poor processes and systems will suffer from even greater productivity challenges, according to this Tech-Clarity research.

Top Performers Turn to Data Management

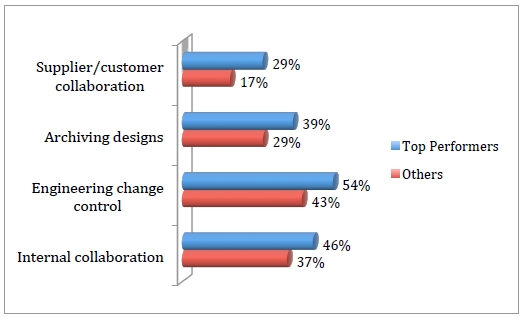

But all is not lost. Tech-Clarity identified the top 24 percent of its respondents based on their ability to design quality, innovative products quickly and efficiently. These companies displayed greater “design data management maturity” than their lower-ranking counterparts, according to the survey. The top performers are, for example, 30 percent more likely to use data management or PLM systems to manage five or more company processes. They’re also more likely to use these tools to collaborate, both with internal company users and external suppliers, vendors, and others.

Beyond common use of data management tools such as vaulting, access control, and CAD-file storage, top performers used their systems for design review and approval, and other functions not readily used by their lower-performing counterparts.

Top performers for product development use their data management systems to control more tasks

Top performers for product development use their data management systems to control more tasks

Cloud file sharing

The survey also found that manufacturers are increasingly using cloud file sharing tools as a component of their data management strategy, and that top performers are using cloud file sharing tools differently than others. For example, top performers that use cloud tools are more likely to implement them with formal processes, while others have ad-hoc processes. And the survey returned hard numbers about just how much data-management systems are aiding company performance.

Impact of high-data management maturity on design efficiency

The Tech-Clarity survey found that companies with “high data-management usage maturity” saw design efficiency improve by two percent, profit margins grow by nine percent and revenues grow by four percent. These companies also found advantages through better integration between CAD tools and design data managements solutions. Those tight integrations led to business performance advantages such as a seven percent growth in revenue and a three percent increase in profit margins, according to the survey. Clearly improving the number of functions supported by design data management solutions provides valuable business advantages that impact both the top and the bottom line. Interestingly the research also showed that top performers foresee higher ROI from future investments in data management than the others in the sample. Top performers see higher ROI potential from extending their data management capabilities

Top performers see higher ROI potential from extending their data management capabilities

Comments