Pushing Synchronous as a CAD Admin

You might have noticed that I’m not exactly neutral in the Synchronous vs Ordered debate. Synchronous was part of the reason for me to start looking at Solid Edge in the first place. So I’m always interested in what people have to say when they want to talk about Synchronous. The last two Solid Edge University events have been great in this regard, there have been some presentations that really stuck with me.

SEU14 brought the much anticipated presentation from Melissa Schultz, which I wasn’t able to make it to personally, but the PDF version of her powerpoint presentation has finally made it to the Solid Edge Knowledge Base. SEU13 brought an unexpected presentation on the topic of Resilient Modeling, given by Dick Gebhart, focusing on a method to make ordered models stable, and mixed Synchronous/Ordered models supremely editable. This blog post is really a collision of those two presentations, and a hope for more real world applications of great concepts like these in the future.

Let’s start with Melissa Schultz’s SEU14 presentation. It was entitled Switching Your Workforce To Synchronous. As the CAD Admin, Melissa had the task of updating the skills of their 70+ Solid Edge users. Most of her presentation talks about management tools used to guide these users who were highly skilled at Solid Edge ordered techniques, and give them some competence with Synchronous tools.

She identified a set of facts and myths that the users seemed to hold:

Fact: Joa users have great Ordered modeling skills

Fact: Ordered is the way we’ve always done it

Fact: If each user only works on their own files, ordered isn’t that bad

Myth: Sync only works for product design, not machine design

Myth: Lose control of the model

Myth: We NEED the history

Another set of facts, however, suggested that learning Synchronous methods would be in everyone’s best interests:

- New features focused in Synchronous

- Ability to have Ordered and Synchronous in the same file

- Remodeling parts because someone else’s file didn’t update

- L-o-n-g wait times when regenerating complex models

- Large assembly models could be helped by smaller file sizes

- Internal strategic plan to reduce engineering time – need to find a way to meet goal

There were obviously a lot of details involved in getting everyone to agree to the training, and to get them to take the training, and she had to address more than just misgivings about the technology – she also had to show how the new methods fit into the internal company standards, and establish new Solid Edge Synchronous best practices. It is an entirely different way of working, after all. Along with the training, she had to coordinate an actual project to work on, and guarantee support would be available for those working on the new project.

She found some general attitudes changing over time, during the training:

• Day one: Confusion/Frustration

• Day two: Useful for someone else

• Day three: I could use it.

She set up a little competition:

• Race – Sync vs Ordered

• Half synchronous, half ordered (then switch)

• Make specific changes

• Existing ordered model created by a good user

• Was changed many times (common for a custom OEM)

• Took time to understand PathFinder

• Showed transfer to Synchronous

• Ordered ½ went from laughing to mad

• Sync users had fun calling out when they were done

The big ideas driving the change, as I read her presentation seemed to be:

- Decreasing engineering time

- Allow anyone to work on anyone else’s models

- Ability to use newly developed features in Solid Edge

I wish I had been able to see Melissa present this in person, but in the end, the transition sounds like it was successful, with maybe a few users reverting to ordered “regardless of the benefits”. We are all familiar with people who approach change that way.

One of the training points that Melissa listed in her presentation was Mixed Ordered and Synchronous Information. This is the point where I get really excited. I believe that the best way to use Solid Edge is to mix ordered and synchronous techniques, and this is where Dick Gebhard’s Resilient Modeling comes in. You can go straight to Dick’s website at ResilientModeling.com. The original idea for this is that you can use this method with any CAD program and make stable models. It is essentially a structured best practice modeling system. But here at Solid Edge, I’m more interested in how you use Resilient Modeling with Solid Edge than with anything else. When you use it with Solid Edge, there’s a big hidden bonus. If you have gone to the website mentioned above, click on the Solid Edge button, and then certainly watch all the videos, but most importantly, watch Chapter 8.

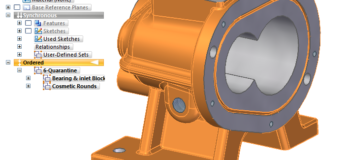

The bonus is that the base prismatic shape that most of your CAD models are made from is highly editable in Synchronous. When you remove all the detail features like rounds, holes, extruded text, draft, etc, your basic shape is very well suited to Synchronous editing. I’m not so interested in the rest of the categories that Mr. Gebhard has invented, but the split between Synchronous and Ordered features as outlined in his Chapter 8 video is perfect. You can do this with a model that was created in Solid Edge Ordered, or to some extent even an imported part. This way of organizing features removes some of the most common reasons for Synchronous edits failing, and it also helps you avoid some of the weaknesses of the parent/child dependencies.

Making models using a highly structured format can be tedious. It pays off later in terms of editability of your parts, and also that anyone can pick up any part, and be able to make changes. These ideas should sound familiar from Melissa’s presentation. The big benefits of Resilient Modeling when implemented for Solid Edge have to do with that Chapter 8. Moving the core prismatic features to Synchronous, and leaving the detail features, thin wall, holes, fillets, etc. as ordered features.

Making models using a highly structured format can be tedious. It pays off later in terms of editability of your parts, and also that anyone can pick up any part, and be able to make changes. These ideas should sound familiar from Melissa’s presentation. The big benefits of Resilient Modeling when implemented for Solid Edge have to do with that Chapter 8. Moving the core prismatic features to Synchronous, and leaving the detail features, thin wall, holes, fillets, etc. as ordered features.

My point is that if Resilient Modeling, or some portion of it, were to be more widely recognized as a best practice for Solid Edge, where you combine the strengths of Synchronous Technology and Ordered methods, CAD administrators like Melissa would not have to work so hard to sell Synchronous Technology to her users. The combination of methods is not a compromise, or even a tilt of the hat to ordered stalwarts, it’s a combination of methods in such a way that the weaknesses of each method are minimized. In the spirit of minimizing weaknesses, Melissa mentioned in her presentation that there would be some exceptions to where you can use Synchronous, and you would have to use ordered – linked part copy, complex bends, and known bugs. I add to that list complex surfacing features. If your plan doesn’t accommodate limitations, which are a reality of CAD usage, it will quickly fall apart when users run into a little adversity.

In addition to having a good method to present to users, we also need a good way of talking about the technology. By necessity all CAD users who have worked in the last 20 years or so are familiar with history-based CAD methods. We’re all familiar with the recipe analogy for history-based model making. But when you say “Synchronous Technology”, few really know what you are talking about. We need a simple phrase that encapsulates the idea of Synchronous. My vote is for something like “selection-based design intent” and you can add “without parent/child dependencies” if you think it needs it.

The fact that the Resilient Modeling scheme emphasizes adherence to standards should appeal to CAD administrators. But a lot of companies don’t have a formal CAD admin position or the person who satisfies that function doesn’t have any real power. Maybe the sales cycle is the best place to sell this sort of ideology. I’m not sure how we should best evangelize these ideas, but CAD admins selling Synchronous to users could benefit from the idea of Resilient Modeling. Maybe some form of Resilient modeling should be built in to Solid Edge itself.

Comments