Solid Edge University Chicago Day 1 Recap

Solid Edge University Chicago is underway, and the day is off to a solid start here in the Windy City. We’re at DMDII—short for the Digital Manufacturing and Design Innovation Institute—one of two centers UI Labs has to revitalize manufacturing in America, where they have not only embraced the future of manufacturing, they are truly living it. I’m joined by more than 40 Solid Edge experts, customers, and partners for an exciting two days during which we will network, share insights, and of course learn more about how people are using the latest technological advancements in Solid Edge 2019.

John Miller, Senior Vice President of Mainstream Engineering, kicked things off with a short welcome this morning, during which he touched on how much we at Siemens value the opportunity to hear directly from you, our customers and really engage in these exchanges of dialogue face-to-face. The most valuable part of these events, at least for me, is the connections we build and the conversations we have together, because that is truly where we can gain real insight into what other people are doing and the innovative ways in which they are using Solid Edge. The passion and excitement is quite catching. There is a lot happening in the design and manufacturing space today!

We talk a lot about digitalization and the ways in which it is completely transforming product development across all industries today, but I was surprised to learn that it’s really SMBs, or small to medium businesses, that are able to capitalize on the competitive advantages of digitalization faster than their larger enterprise brethren. Of course, it makes sense when you consider the size and scope of some larger organizations—Change in such companies can be slow, and it often takes longer to adopt newer technologies and fully integrate those into the existing processes. The key takeaway? If you are a small-medium business and you’re NOT seizing the opportunity to digitalize your business, you need to start because it is a significant chance to get ahead of even larger companies.

Next we heard from Dan Staples, Vice President of Mainstream Engineering Product Development, and Craig Ruchti, Application Engineer, who gave us a high-level introduction to Solid Edge 2019. Of course there is far more information than anyone could cover in a single hour-long session, let alone a paragraph in a blog post, so I will just share a few of the highlights. (Check our knowledge base for details of each new feature added in Solid Edge 2019!).

First, generative design is not just for aerospace and automotive applications. Think about this—if you reduce material weight by 25%, as one of our customers did, every fourth part you produce is free! In terms of core CAD functionality, which is what most people ask about when it comes to what’s new in Solid Edge 2019, auto-simplify stands out for its ability to quickly and easily simplify geometry with the push of a button to easily share geometry with others without giving away proprietary information.

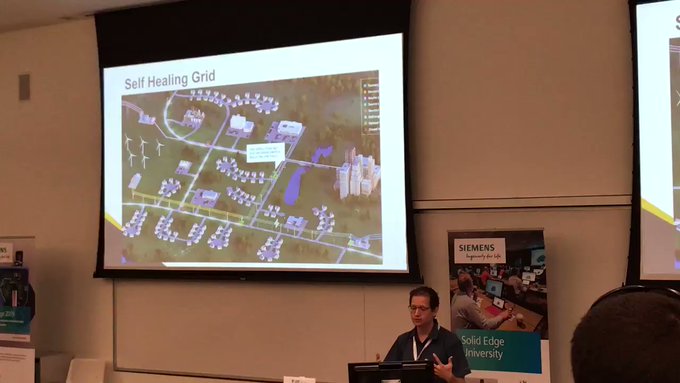

One of my favorite presentations though came from Carl Breving of S&C Electric Company. S&C Electric is a global provider of equipment and services for electric power systems.With more than 3,000 employees, it is second largest manufacturing company in Chicago. Among the company’s many specializations are smart grids and self-healing grids. The self-healing grids in particular are captivating, because they have the ability to isolate faults and restore service within seconds to minutes, compared to the traditional timeframe of hours that many of us are familiar with.

Self healing grid by S&C Electric Carl Breving #SolidEdgeU Chicago #SolidEdge pic.twitter.com/kz1tg28pmb

— Marianne Stokes (@stokesautomatio) September 17, 2018

S&C Electric has been using Solid Edge since v1 in 1996, and they do a lot of interesting stuff in the realm of customization and integration with different systems and apps to accomplish their needs. In the area of automated design systems, they recently moved to Siemens Rulestream in order to have a standard platform and interface for design automation development. By capturing knowledge and storing it as rules in this system, they are able to retain the knowledge and expertise of teammates that would otherwise be lost as these individuals leave or retire from the company. For example, Carl mentioned that one rule they stored captured the knowledge of two employees with a collective experience of 95 years! Isn’t that amazing? I’m hoping to have a chance to speak with him more for a follow up blog that will explore the cool things S&C Electric is doing a bit more in depth, so stay tuned!

Comments