The Rising Demand for Routed Electrical Collaboration

A couple of weeks ago, I published an article that focused on the need for collaboration between electrical and mechanical engineers called It Takes Two: Modern Circuit Board Design. In it, I wrote that the development of circuit boards really does require some tight work back and forth between these two types of engineers because there are constraints on both sides that need to be satisfied.

Well, circuit board design isn’t the only aspects of smart, connected products that require electrical and mechanical engineers to work in concert. Routed electrical systems, composed of wires, cables, and harnesses is another aspect. That’s what we’ll be diving into with this post.

Harnesses: The Nervous System of Smart, Connected Products.

Before we get into the details, let’s revisit the anatomy of a smart, connected product. Sensors are the senses. Embedded systems made of software, processors, and circuit boards are the brains. Antennas are the voice, allowing products to communicate with anything else. Actuated components act as the muscles of the product, allowing them to affect their environment and their operation.

All that stuff has to be interconnected. Sensors send data to the embedded system. Embedded systems send data to the antenna to talk with IoT platforms. Embedded systems send signals to actuated components.

Connecting all those things and delivering power to them is the purpose of a harness. In that way, it is the nervous system of the product.

Harnesses: Logical and Physical Representations

A key thing to recognize about harnesses is that they have two markedly different representations: a logical one and a physical one. Let’s talk about each for a moment.

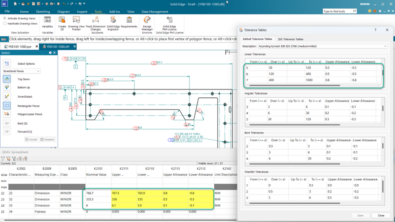

The logical representation of a harness is its diagram or schematic built in an ECAD application. It shows which wires connect which sensors, antennas, circuit boards, and actuated components. In this representation, everything gets connected with wires. Developing this logical representation is the responsibility of the electrical engineer.

The physical representation of a harness is the routing of wires and cables through the 3D mechanical assembly in MCAD application. This is where those wires and cables are geometrically represented, starting from connectors, coupled with other wires and cables into harnesses, passed through channels, and terminated with other connectors. Routing the harness through the 3D mechanical assembly is the responsibility of the mechanical engineer.

Harnesses: Collaborative and Iterative Design

Seems like the electrical engineer could develop the logical diagram, pass that underlying connectivity information to the mechanical engineer, and allow them to route the harness, right? Well, yes. That’s what happens in the first pass. However, that’s not the end. That’s the beginning.

Like anything that is designed, there are constraints.

From an electrical perspective, there are all sorts of requirements that have to be satisfied. If a wire delivering a signal is too long, then that signal might be too weak to register at the electronic endpoint. A wire delivering high voltage power might give off an electromagnetic field that interferes with electrical signals so that one might need to be shielded or routed on its own.

On the mechanical side of things, there are constraints too. Certain wires in a section of the product might be required to have a drip loop so that liquids can drip harmlessly instead of going into the connector. They might need to avoid certain areas of the product where there are active linkages that might pinch and cut cables.

So this isn’t a one pass activity. Both the diagram and the routing need to be checked against constraints. If there are problems, they need to be resolved. Yet, those problems are rarely something that is fixed simply. The electrical engineer and mechanical engineer need to both assess potential solutions, citing each of their constraints.

That’s why harness design is fundamentally a collaborative and iterative design activity between an electrical and mechanical engineer.

Right Combination of ECAD and MCAD

This combined need-to-work-together-collaboratively is something that software solutions can address. In fact, it is crucial that the ECAD and MCAD applications pass associative changes back and forth to enable this kind of iterative and collaborative design effort.

In a recent post titled Harness Design: On the Critical Path, I wrote about some key capabilities of ECAD and MCAD applications in order for electrical and mechanical engineers to accommodate more change so harnesses could be designed concurrently with electrical endpoints. Those capabilities are imminently applicable here as well.

“A critical new capability that has recently emerged is tighter associativity between the ECAD application used to develop the harness’ schematic and the MCAD application used to route that harness’ wires through the 3D mechanical assembly. As a power, network, or other requirements for an electronic endpoint changes, the electrical engineer makes a change to their harness schematic. It might be to change the wire type, its color, switching wires, or something else. Once that is done, that change is seamlessly and automatically propagated to the harness design in the 3D mechanical assembly. This concept of associativity provides some control to the electrical engineer and the mechanical engineer involved, allowing them to visualize what has changed. However, it also gives them the capability to quickly and easily make that change to the routing. This is one way that these two engineers can more readily accommodate change.”

This capability, to associativity pass changes back and forth, is a critical enabler for designing harnesses collaboratively and iteratively. However, there is another capability that allows electrical and mechanical engineers to address more complicated design issues: interactive highlighting.

“Now all changes to the constraints on harnesses, however, aren’t so simple. Some don’t just require a change to the wire type. In some cases, a whole set of wires must be replaced and rerouted. That might require collaborative and iterative work back and forth between the electrical and mechanical engineers. That, though, brings up some challenges. An electrical engineer can’t easily look at the harness routed through the 3D mechanical assembly and understand how it relates to the harness schematic. The mechanical engineer can’t easily look at the harness schematic and understand how it relates to the 3D mechanical assembly. Each needs their familiar context to have a collaborative and iterative discussion.”

“This is where the second key capability comes into play: interactive highlighting. It may not seem groundbreaking, but in these circumstances, it is crucial. The idea is that a wire in the harness schematic can be selected and the corresponding wire in the harness routed through the 3D mechanical assembly highlights simultaneously. The same is true going the other direction, selecting wires in the 3D mechanical assembly and seeing it highlight in the harness schematic. This interplay, back and forth between ECAD and MCAD applications, is a key enabler to having collaborative and interactive discussions about how to resolve a complex change to a harness.”

This means of interactive highlighting while still allowing each engineer to work in their preferred environment where they can visualize changes is crucial.

Recap

- Harnesses are the nervous system of smart, connected products. They connect sensors, embedded systems, antennas, and actuated components so they work as a single whole.

- Harnesses have a logical representation, a diagram developed by the electrical engineer, and a physical representation, the harness’ routing through the 3D mechanical assembly.

- It takes more than a simple handoff from the electrical engineer to the mechanical engineer to design a harness. There are constraints and requirements that must be checked along the way. Problems must be resolved collaboratively and interactively between the pair of engineers.

- New capabilities, including tight associativity and interactive highlighting between ECAD and MCAD applications, are crucial to enabling electrical and mechanical engineers to address design issues in the development of harnesses.

Alright, folks. That’s my take. Let me know your thoughts in the comments below.

Comments