The Latest in Teamcenter Easy Plan

What’s New in Teamcenter Easy Plan?

I’m happy to share that we’ve introduced new functions with the latest release of Teamcenter Easy Plan to help you and your teams work more efficiently in your manufacturing process planning initiatives.

With each new release of Easy Plan, we aim to deliver the best possible manufacturing planning user experience with our award winning manufacturing process management technology.

Below are some of the highlights of the latest release of Easy Plan. To get a closer look at what’s new, contact your Siemens or partner sales representative.

Author Electronic Work Instructions More Efficiently

In the area of Electronic Work Instructions authoring, you can now re-sequence images and visuals by renaming them. You can add symbols, and allow the application to assist you in proposing assigned parts for the text. You can now add background parts to the visual instructions, and identify where assembly level product manufacturing information (PMI) is defined in the engineering bill of materials (EBOM).

- Manage background parts for graphical work instructions

- Rename visuals for re-sequencing

- Add symbols to the textual work instructions

- Auto-complete consumed parts and assigned resources

- Find where assembly-level Product Manufacturing Information (PMIs) are defined in the EBOM

Find where assembly-level PMIs are defined in the EBOM in Easy Plan

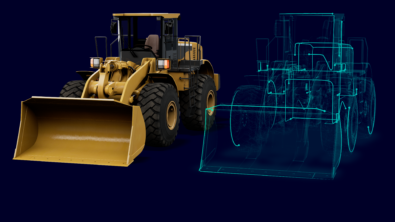

Optimize Your Work With 3D Viewer

You can also work more efficiently with the 3D viewer. You can view the assignment indications in a graphical way, easily select multiple parts in the viewer, and make sure your operations are revised before modifying product views.

- View 3D Assignment Indication

- Select multiple parts in 3D viewer

- Show/hide multi objects in the 3D viewer

- Revise an operation for authoring product views (using Teamcenter Visualization)

Improve Engineer to Order Processes

In the area of process planning for the Engineer to Order (ETO) industry, you can now also author small products that do not require a high level breakdown. You can set time and variant information on operations, assign reference parts to operations and share files on the cloud with partners.

- Add variant formula to operations in Assembly planning and Work Instruction tasks

- Assign Reference Parts to Operations

- Plan small products with classic BOP

Improve Build to Order, Build to Stock, and Configure to Order Processes

In the areas of Build to Order (BTO), Build to Stock (BTS) and Configure to Order (CTO), you can now set the occurrence type for assigned parts and tools in an operation to distinguish between parts that need to be consumed in the stations, from parts that need to be in the station for different purposes. You can use MTM graphical data cards when performing detailed time analysis. You can create scope flows between process areas in the plant BOP.

- Set occurrence type for assigned parts and tools

- Use MTM graphical data cards for detailed time analysis

- Author flows between different levels of the plant BOP areas (Scope Flows)

Share Manufacturing Process Planning Information in the Cloud

Easy Plan now supports an easy and secure way of collaborating with users internal and external to your organization – using Xcelerator Share. It’s as easy as identifying the files to share, and specifying an Xcelerator Share project with assigned users to share the data with.

Manufacturing BOM (MBOM) Management Enhancements

The MBOM Manager has been enhanced to enable work package creation using items instead of revisions. This removes the need to create dedicated work packages for each revision, helping you to work more efficiently. In addition, you can now copy paste, cut paste, check in, and check out parts. Usability enhancements have also been added to the toolbar commands. Also, you can leverage a usage BOM for manufacturing, where you can assign usage parts from the EBOM to the MBOM.

- Create Work Package using items instead of revisions

- Copy-Cut-Paste parts in MBOM

- Check-in Check-out parts

- Improved usability for MBOM Management toolbars

- Align Usage BOM with MBOM

Rulestream Automation for Process Plans

You can now leverage the rules defined in the Rulestream application for automatic generation of process plans. For example, an expert can define the rules in Rulestream as a one-time action, then as a planner, you can generate the Bill of Materials, Bill of Process, and part assignments in a single click. The rules defined in Rulestream will be used for structure generation. You can also add capabilities to operations in a product BOP in the operation library tree.

- Automatically create process plans using Rulestream

- Define operation capabilities in a product BOP

Why Manufacturing Process Planning with Teamcenter Easy Plan?

Easy Plan will help you shift your manufacturing planning activities earlier in the product lifecycle, and enable collaboration between manufacturing and design teams, providing early visibility to potential issues. Easy Plan, built on the Teamcenter PLM backbone, supports a digital thread for controlled and consistent data flow between manufacturing execution systems, and design and manufacturing engineering.

- Author, analyze and manage manufacturing plans more efficiently

- Communicate plans throughout your organization and extended enterprise more effectively

- Immediately access optimization and validation tools directly from your process plans

Learn More About Teamcenter Easy Plan

See a demonstration of Easy Plan here.

Explore Easy Plan at your own pace with a free software trial.