Integrated Parameter Management sews together the Digital Thread

Deliver seamless products without program failure

Do you ever face challenges joining your business and development processes to build and deliver products that meet the target of the overall product? Developing a new product or improving the performance of an existing one is a high-risk process with the possibility of many programs failing. To ensure the program delivers the planned goals, all stakeholders participating in the product development must be working towards a set of unambiguous and measurable targets which can be verified at each stage of development. Let’s look at how Siemens can help you overcome this challenge with integrated parameter management based on the Teamcenter platform.

Sew Digital Threads with Teamcenter Parameter Management

What if you removed all of the threads from your bags, sheets, and clothes? What would they be then? Certainly, they would not be useful without the multiple strands sewn together. Where a thread of yarn would connect bags, sheets, and clothes, Teamcenter Parameter Management helps you to sew a digital thread connecting all your stakeholders.

- Capture product targets and propagate them to system and subsystems

- Design system and subsystems to achieve their respective sub-targets

- Verify that the resulting product meets overall product targets

In the video below, see how to collaboratively parameterize the digital thread to set product targets, derive functional and physical characteristics, and close the loop with automated validation of products targets.

The scenario in the video illustrates how product development stakeholders can sew the digital parameter thread all together:

- Hearing the voice of the customer, Ben, the Product Owner, is requesting to increase the non-stop range of a fully-loaded diesel semi-truck to be 2500 kilometers

- Ed, the feature owner, will be evaluating several options to meet the new product performance target, like improving the vehicle fuel efficiency and/or increasing the fuel tank capacity

- Before Linda, the mechanical designer, implements the recommended solution, Sam, will simulate the change through a virtual prototype and validate it would meet the new non-stop range target – Test before you change!

- To close the loop, Ben will review the new solution design. He may not accept it if it violates the safety requirements

Smash Product Goals through Digital Parameter Thread

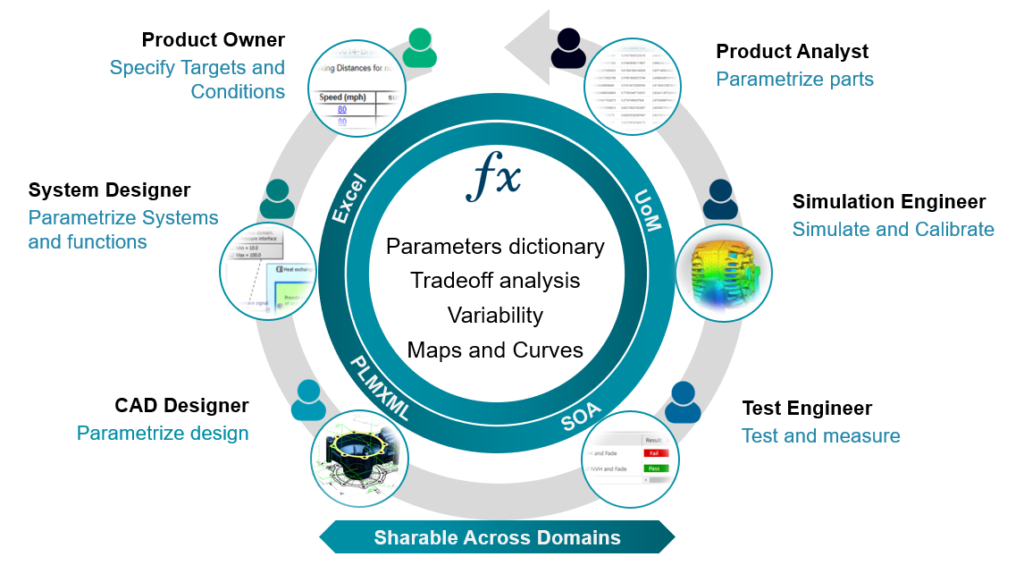

The process of cascading unambiguous and measurable targets is critical in product development, especially for complex systems. You can flow your product goals through the digital parameter thread using Teamcenter Parameter Management integrated with:

- Requirement management to set product targets

- System Modeling Workbench and NX to derive functional and physical product characteristics

- Verification Request and Teamcenter for Simulation to automate design verification and validation.

By enabling your product development stakeholders to sew together the digital parameter thread, you can shorten the product design cycle time, avoid design iterations late in the development cycle, and increase the likelihood that expensive physical prototypes will be closer to product targets and quality. To learn more please visit the MBSE web page or view other blogs on model based systems engineering