MCAD Design Management and Model-Based Enterprise (MBE): More than a 3D Model and PMI

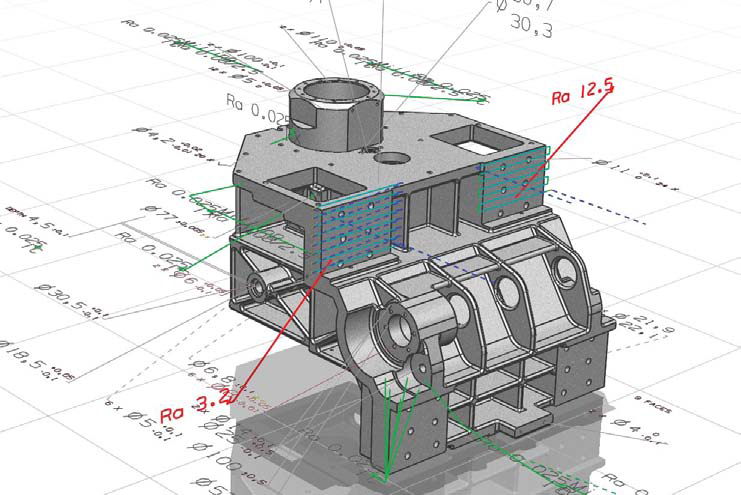

MBE more than 3D model and PMI We hear a lot today about companies trying to improve productivity and product quality by establishing Model Based Design, Model Based Definition (MBD), and Model Based Enterprise (MBE) initiatives in their MCAD and Multi-CAD design management environments. Traditionally, these initiatives involved processes for the management, control, release and exchange of 3D models and Product Manufacturing Information (PMI).

Organizations such as INCOSE, NIST, MBE.org and others define MBE as having seven levels of maturity, or gates to success:

-

- Level 0: Drawings centric – Primary deliverable: 2D Drawings

-

- Level 1: Model centric – Primary deliverable: 2D Drawing and neutral CAD model

-

- Level 2: Model centric – Primary deliverable: 2D Drawing and native CAD model

-

- Level 3: Model based definition – Primary deliverable: 3D annotated model and light-weight viewable

-

- Level 4: Model based definition – Primary deliverable: 3D annotated model and light-weight viewable via PDM

-

- Level 5: Model based enterprise – Primary deliverable: Digital product definition package and TDP

-

- Level 6: Model based enterprise – Primary deliverable: Digital product definition package and TDP via the web

MBE and the Digital TwinAs you can see in these levels of maturity there is a big jump from level 2 to 3, which requires moving off of 2D drawings as well as from level 3 to level 4 which entails moving to Product Data Management (PDM). Through each of these levels you can see the product data, or Digital Twin beginning to mature, but since the models evolve, multiple configurations or variants are involved and many stakeholders across the entire value chain add or modify the information throughout the products entire lifecycle, this type of product information on is not enough.

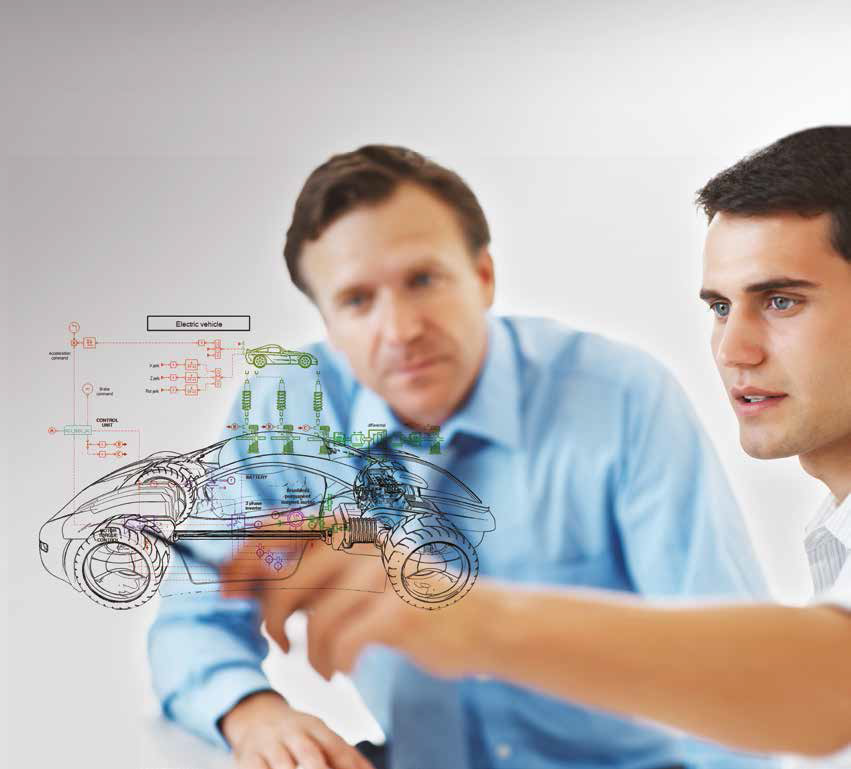

To truly improve productivity and product quality requires the implementation of a Product Lifecycle Management environment that enables an integrated Model Based Enterprise (MBE) approach that not only fully embraces the delivery of Technical Data Packages associated with the Digital Twin, but also connects the processes, procedures and information from across the entire design through delivery value chain referred to as the Digital Thread.

Digital Thread encompasses the processesOnly as companies adopt effective MBE initiatives and mature their digital thread and digital twin capabilities will they be able to improve productivity, increase quality and transform their business processes to achieve greater business value. Regardless of where you are in your adoption of an MBE initiative, Teamcenter can support all the functions and levels associated with management of the Digital Twin and Digital Thread.

For more information on the terminology, issues and benefits of MBE initiatives, please review the Lifecycle Insights eBook on the MCAD/Multi-CAD Design Management page of the Siemen PLM website entitled CAD and PLM crucial to enabling MBE initiatives.

About the author Dennis George is a marketing manager for Siemens PLM Software’s Teamcenter PLM software. Through his involvement with a number of market segments, Dennis has gained valuable insight into the issues, flows, and processes employed in the design and manufacturing of software-driven electronic systems and components